Building material composition containing aeolian sand and preparation method of building material composition

A technology for building materials and aeolian sand, which is applied in the field of building material compositions containing aeolian sand and its preparation, and can solve the problem that Brandt cement cannot support qualified strength, aeolian sand is not suitable for building aggregates, and high doping content and other problems, to achieve the effect of reducing production cost and preparation difficulty, easy production and deployment, and high doping amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

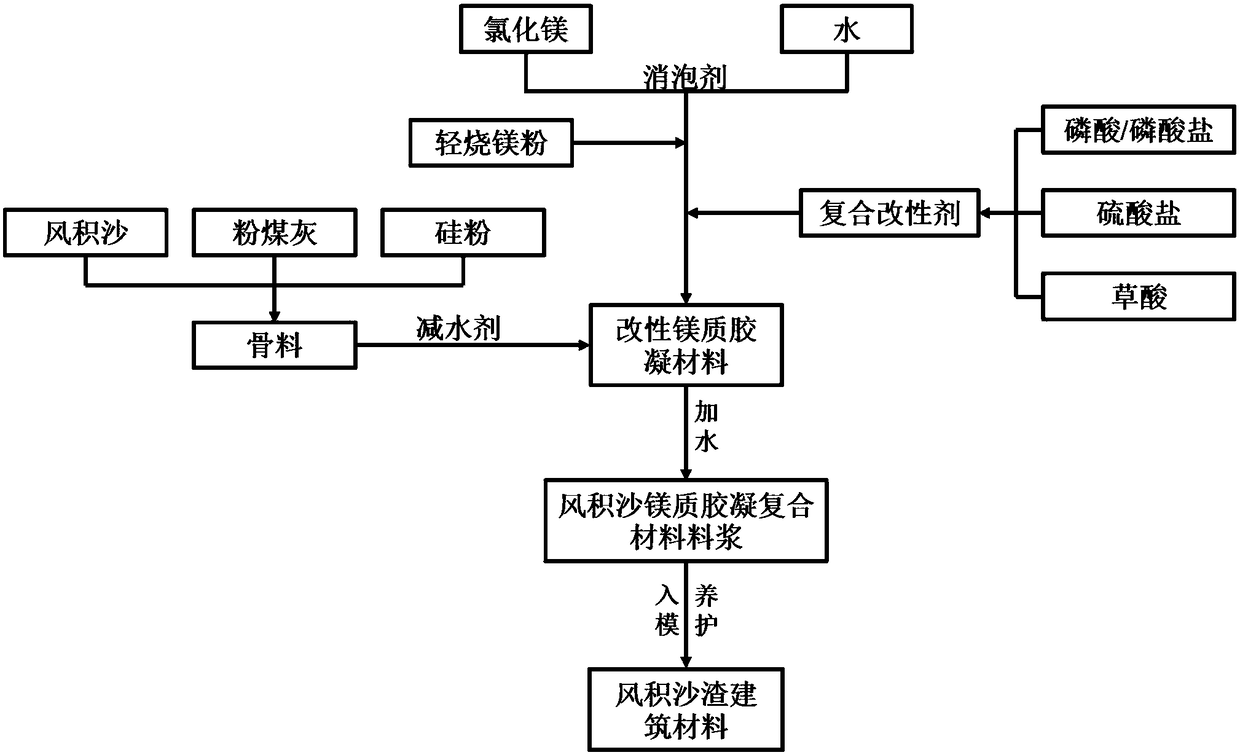

[0033] A preparation method of a building material composition containing aeolian sand, comprising the following steps:

[0034] (1) Magnesium chloride brine preparation: the magnesium chloride is configured into an aqueous solution with a concentration of 20% to 30%, an antifoaming agent is added, and fully stirred until the magnesium chloride solution foam is eliminated and becomes a clear solution;

[0035] (2) Preparation of composite modifier solution: the following composite modifier raw materials are proportioned by weight: phosphoric acid and / or phosphate 5~40%, sulfate 10~80% and oxalic acid and / or sodium oxalate 0~ 50% soluble in water;

[0036] (3) Preparation of modified magnesia gel material: add light-burned magnesia powder to the magnesium chloride aqueous solution prepared in step (1), stir for 2 to 5 minutes, and then add the composite modifier prepared in step (2) In the solution, continue to stir for 3 to 5 minutes;

[0037](4) Aggregate mixing: adding aeo...

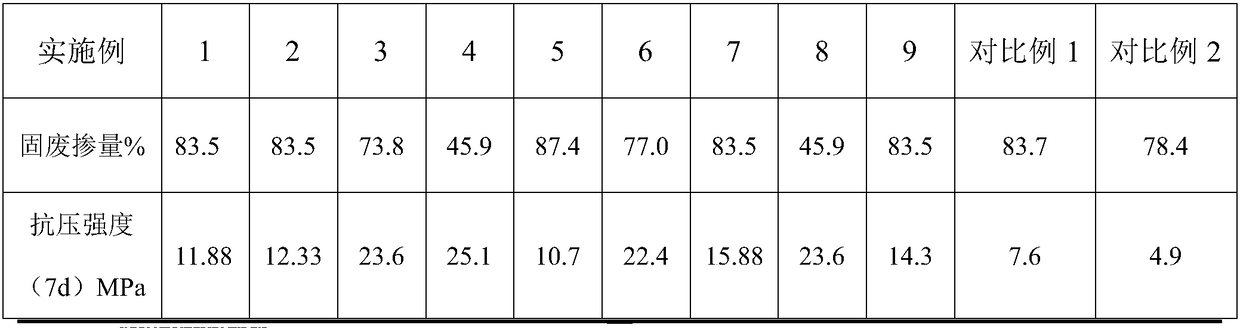

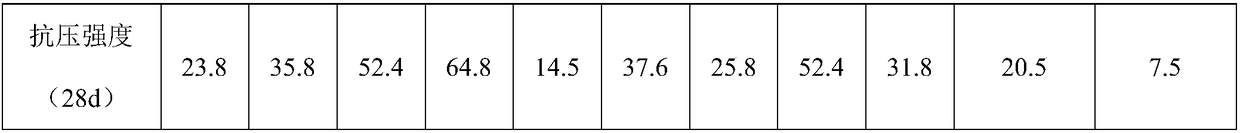

Embodiment 1

[0043] Such as figure 1 As shown in the process, this embodiment provides a method for preparing a building material composition containing aeolian sand, comprising the following steps:

[0044] (1) Magnesium chloride brine preparation: the magnesium chloride is configured into an aqueous solution with a concentration of 26%, and 1.5 g of emulsified silicone oil defoamer is added, and fully stirred until the foam of the magnesium chloride solution is eliminated and becomes a clear solution;

[0045] (2) Preparation of composite modifier solution: dissolve 1.95g of phosphoric acid and 2.9g of ferrous sulfate in 35.15g of water, stir evenly, and configure 40g of composite modifier solution;

[0046] (3) Preparation of modified magnesia gel material: add 195g of light-burned magnesia to 156g of the magnesium chloride solution prepared in step (1), stir for 5min, then add the composite modifier solution configured in step (2) 40g, continue to stir for 3 minutes to fully mix the m...

Embodiment 2

[0053] This embodiment provides a method for preparing a building material composition containing aeolian sand, comprising the following steps:

[0054] (1) Magnesium chloride brine preparation: the magnesium chloride is configured into an aqueous solution with a concentration of 20%, and 4.5 g of high-carbon alcohol fatty acid complex defoamer is added, fully stirred until the magnesium chloride solution foam is eliminated and becomes a clear solution;

[0055] (2) Preparation of composite modifier solution: dissolve 2g of phosphoric acid, 2g of trisodium phosphate and 2g of oxalic acid in 34g of water, stir evenly, and configure 40g of composite modifier solution;

[0056] (3) Preparation of modified magnesia gel material: add 195g of light-burned magnesia to 284g of the magnesium chloride solution prepared in step (1), stir for 5min, then add the composite modifier solution configured in step (2) 40g, continue to stir for 3 minutes to fully mix the materials;

[0057] (4) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com