Drilling, grouting and sand-throwing process of ground surface of mined-out region under highway

A drilling technology for highways and ground surfaces, which is applied in infrastructure engineering, construction, soil protection, etc., can solve the problem of high cost of full filling materials, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

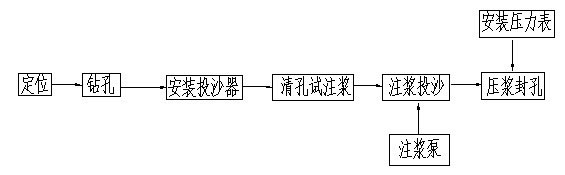

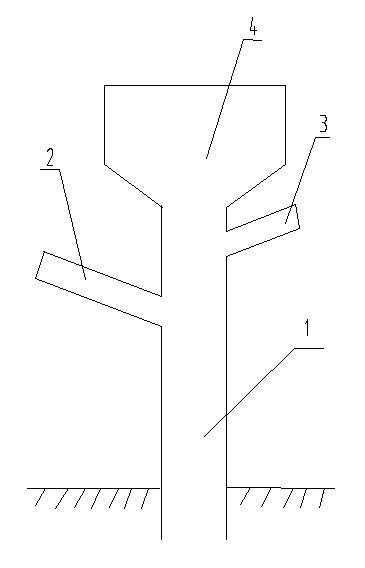

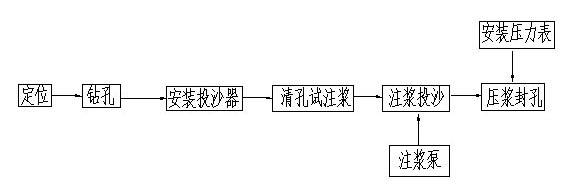

[0032] Such as figure 1 , 2 Shown:

[0033] 1. Surface drilling, grouting and sand throwing technology in gobs under the expressway, including drilling, pulping and grouting and sand throwing technology, of which:

[0034] Drilling includes fixed point, drilling rig installation and hole forming,

[0035] Fixed point: use theodolite or total station measuring instrument to carry out field stakeout according to the designed hole position;

[0036] Drilling rig installation: find out the hole position according to the mark set in stakeout, and install the drilling rig;

[0037] Hole forming: After the drilling rig is positioned, use a composite drill bit to open the hole, maintain the wall of the hole with the retaining conduit, drill to the lower retaining conduit 3-5m away from the stable bedrock, and reduce the drilling diameter at the lower part to 89mm. The final hole of the roof of the drop belt or goaf;

[0038] 2. The pulping process is carried out according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com