Desert area migratory dune land railway bed construction method

A technology of railway subgrade and construction method, applied in the directions of roads, roads, tracks, etc., can solve the problems of sparsely populated, difficult to build transportation access roads, and a large number of railways, and achieve the effect of shortening the line mileage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

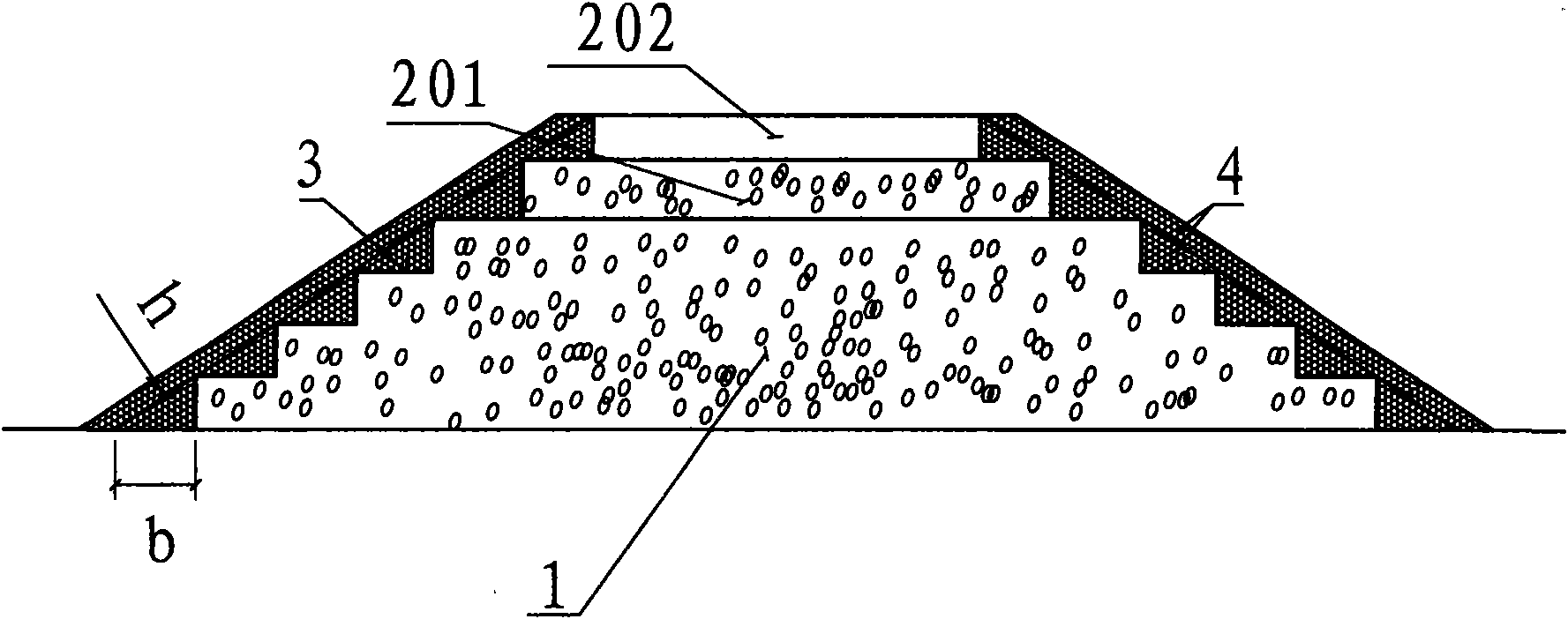

[0019] For the construction method of the railway subgrade in the mobile sand dune area in the desert area, the preliminary work is the same as that of building railways in other areas, and the subgrade measurement is carried out first. In order to prevent the control piles from being submerged due to the action of mobile sand dunes, the measurement control piles should be buried firmly, and protective piles should be set around the control piles; for the convenience of water, water wells should be drilled along the road construction, and the number of wells suitable for water consumption should be determined according to different distances ; Then construct according to the following steps:

[0020] A. Leveling and rolling: the original ground is leveled and rolled; the subgrade surface is 25 meters, and pure aeolian sand is spread on the rolled subgrade surface;

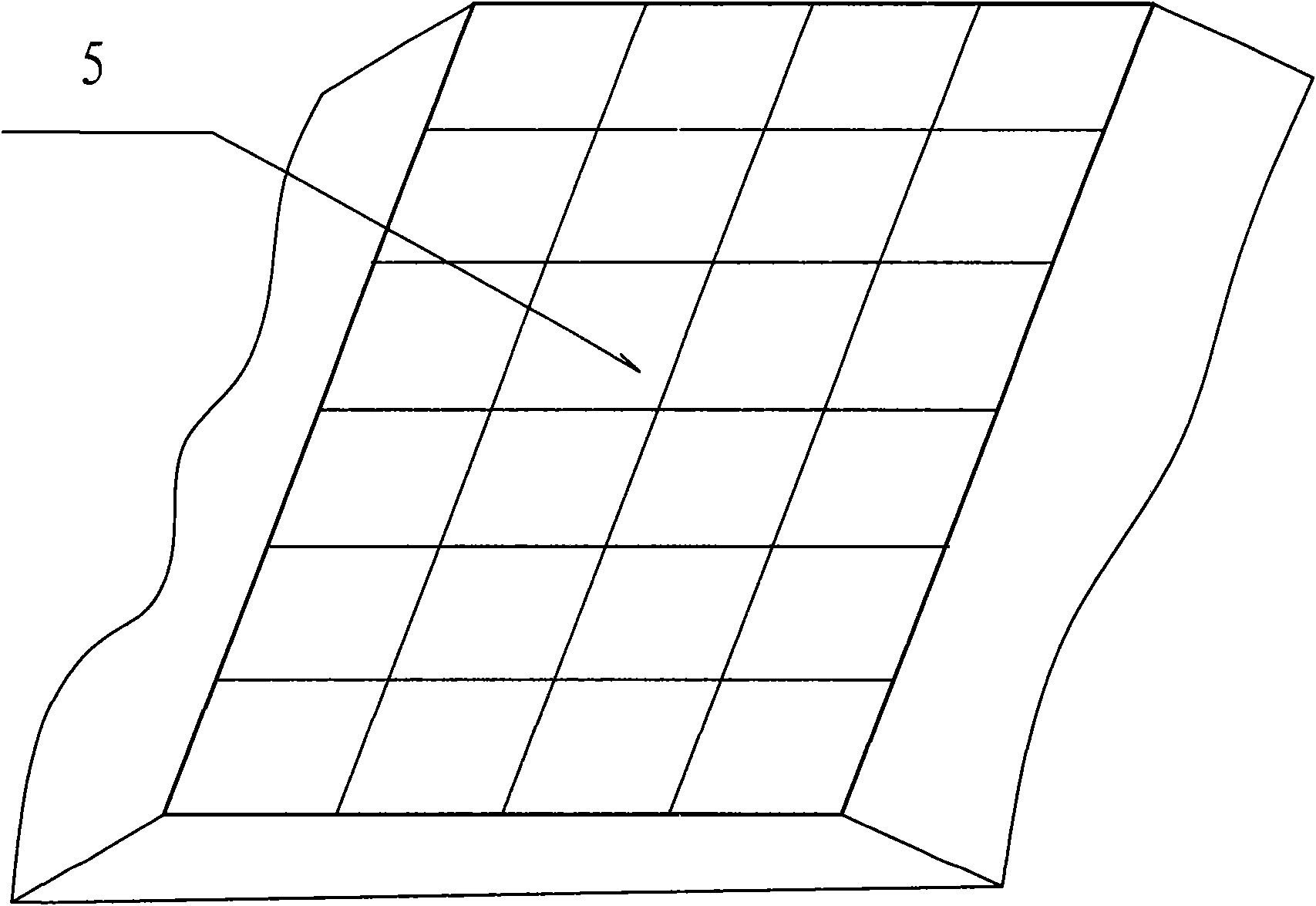

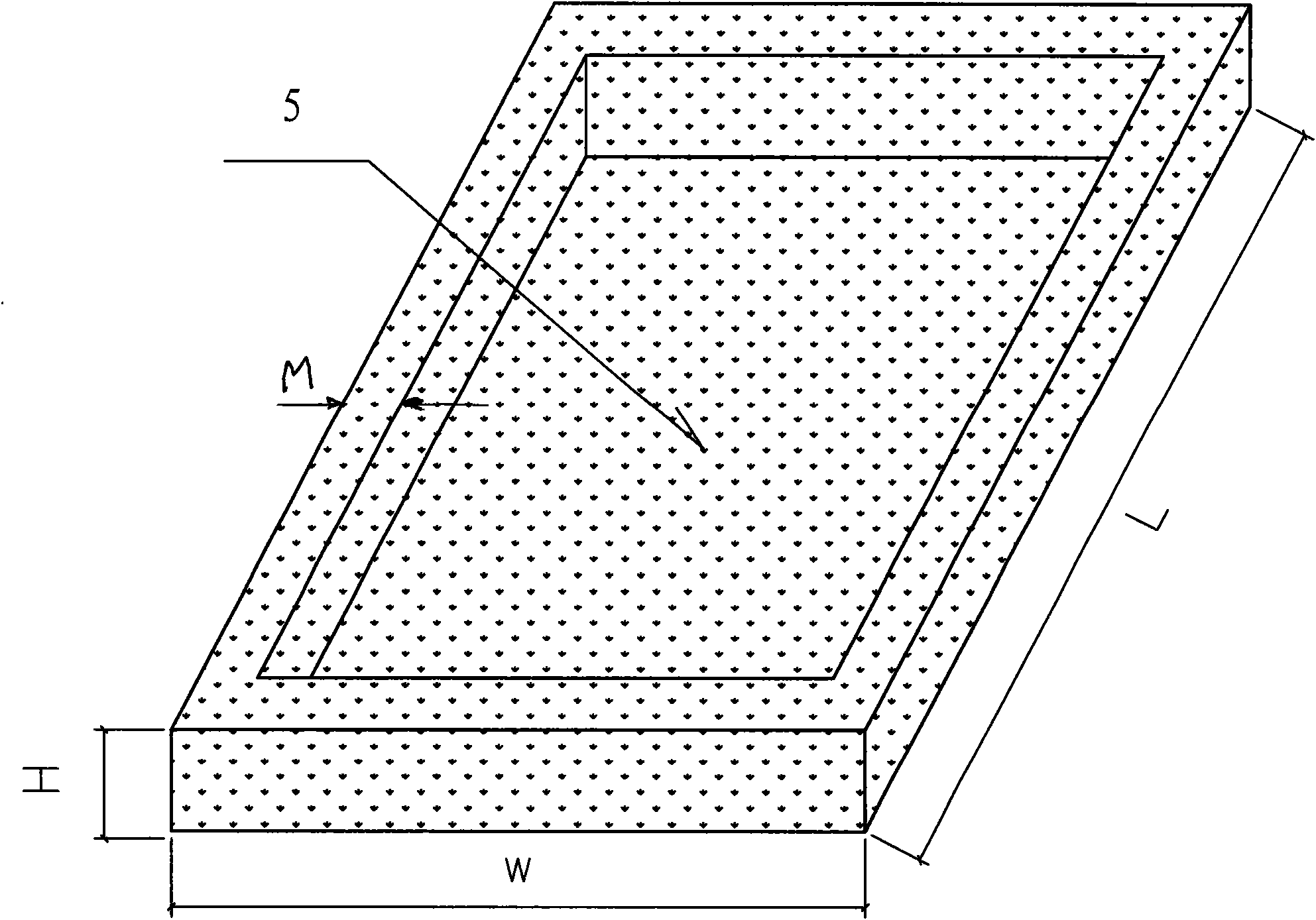

[0021] B. Set up grid cofferdam: see figure 2 and image 3 , divide the pure aeolian sand paved on the subgra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com