Mems light valve, manufacturing method thereof, and display device having the mems light valve

A manufacturing method and light valve technology, which are applied in optics, optical components, static indicators, etc., can solve the problems of high power consumption and large moving distance of MEMS light valves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

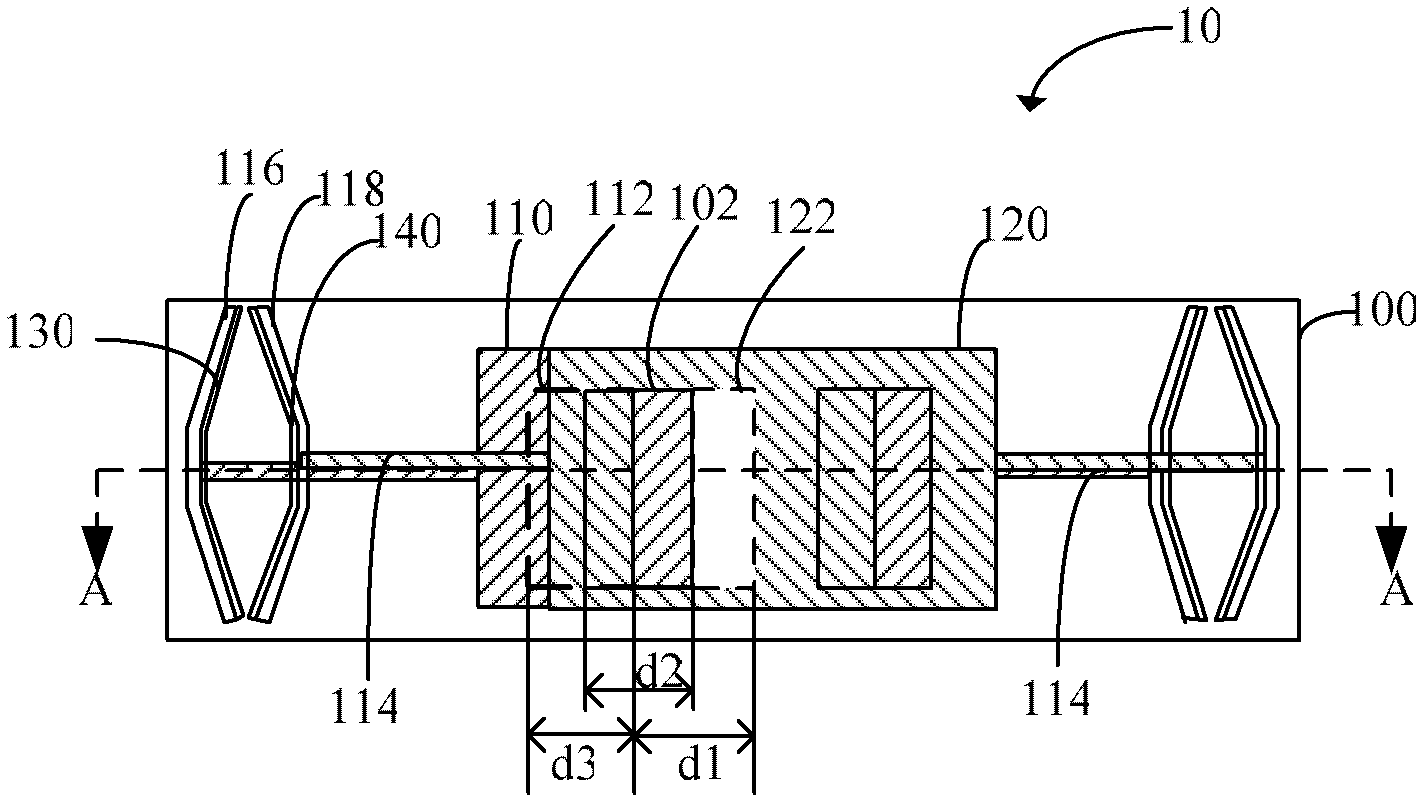

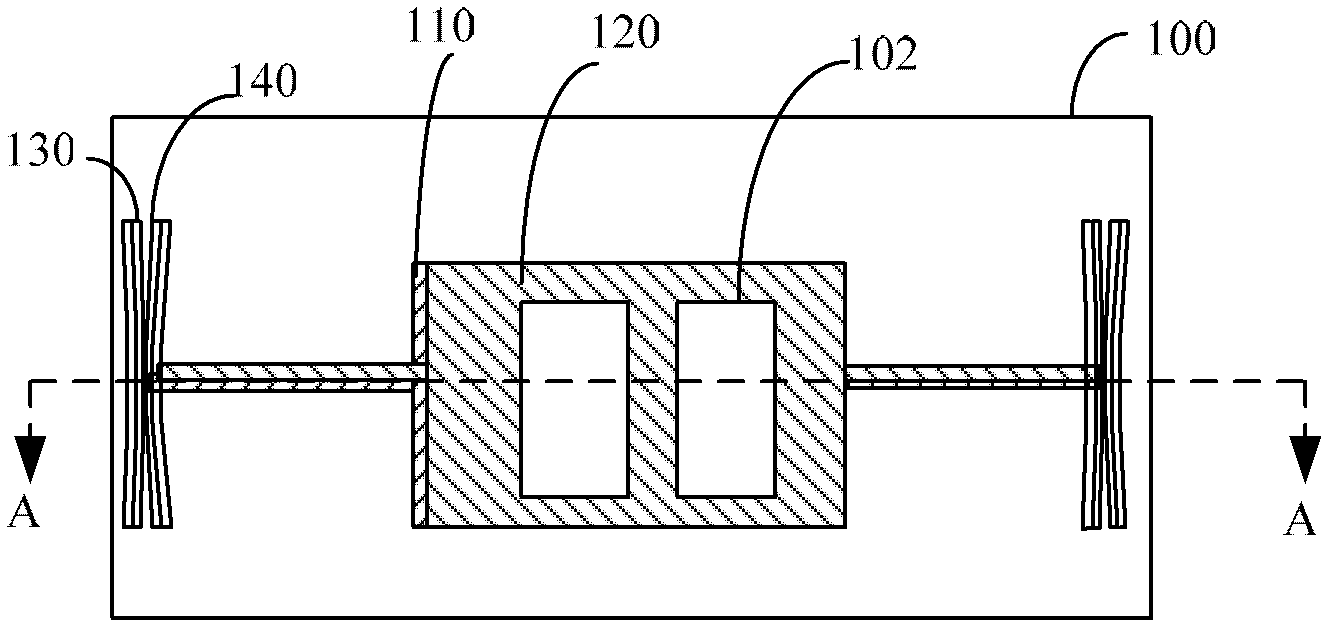

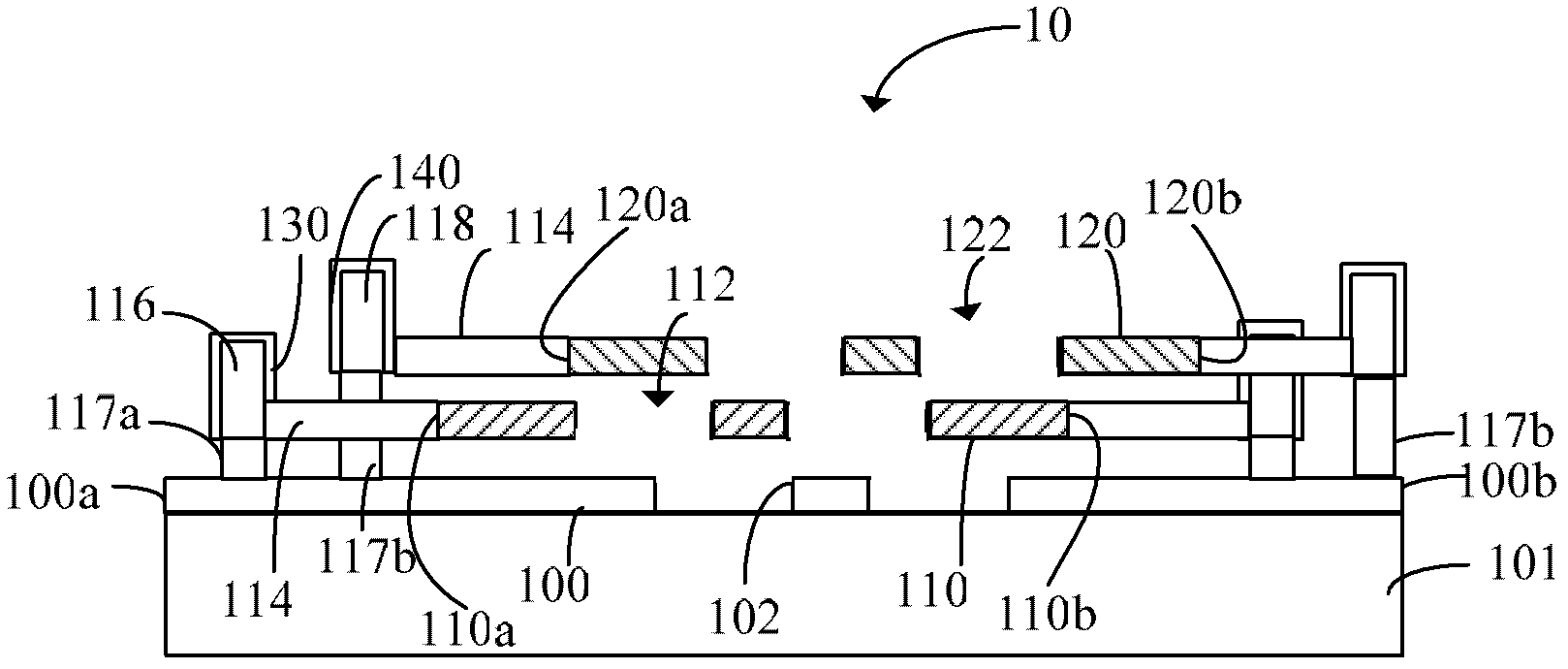

[0065] figure 1 is a schematic plan view of the opaque state of the MEMS light valve in the first embodiment of the present invention; figure 2 It is a schematic plan view of the light-transmitting state of the MEMS light valve in the first embodiment of the present invention; image 3 yes figure 1 The MEMS light valve shown along the figure 1 The schematic diagram of the cross-sectional structure in the A-A direction shown; Figure 4 yes figure 2 The MEMS light valve shown along the figure 2 The schematic diagram of the cross-sectional structure in the direction A-A is shown. Combine below Figure 1 to Figure 4 Specific examples of the present invention will be described.

[0066] combined reference Figure 1 to Figure 4 , the MEMS light valve of the present invention includes: a fixed grating 100, a first movable grating 110 and a second movable grating 120 stacked in layers; a first electrode 130, which is connected to the first movable grating 110; An electrode...

no. 2 example

[0083] Figure 6 is a schematic plan view of the MEMS light valve according to the second embodiment of the present invention. In the second embodiment, as Figure 6 As shown, the fixed grating 200 is circular and has a circle of openings on it. Of course, the openings can also be an array of openings arranged in an array along the circumference. In this embodiment, only one circle of openings is used. Take this as an example.

[0084] The first movable grating 210 is circular and stacked parallel to the fixed grating 200 . The first movable grating 210 has a plurality of openings 212 , and the openings of the first movable grating correspond to the openings of the fixed grating. The first movable grating 210 is correspondingly arranged above the fixed grating 200. The intersection points of the same diameter and the circumference of the first movable grating 210 are respectively connected with suspension rods 214. The suspension rods 214 are connected with the first elastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com