Construction method for processing aeolian sand roadbed base through impacting and grinding

A technology of impact rolling and wind treatment, applied in the direction of roads, roads, road repair, etc., can solve the problems of large settlement, low water content, loose aeolian sand structure, etc., and achieve the effect of reducing engineering costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings of the description.

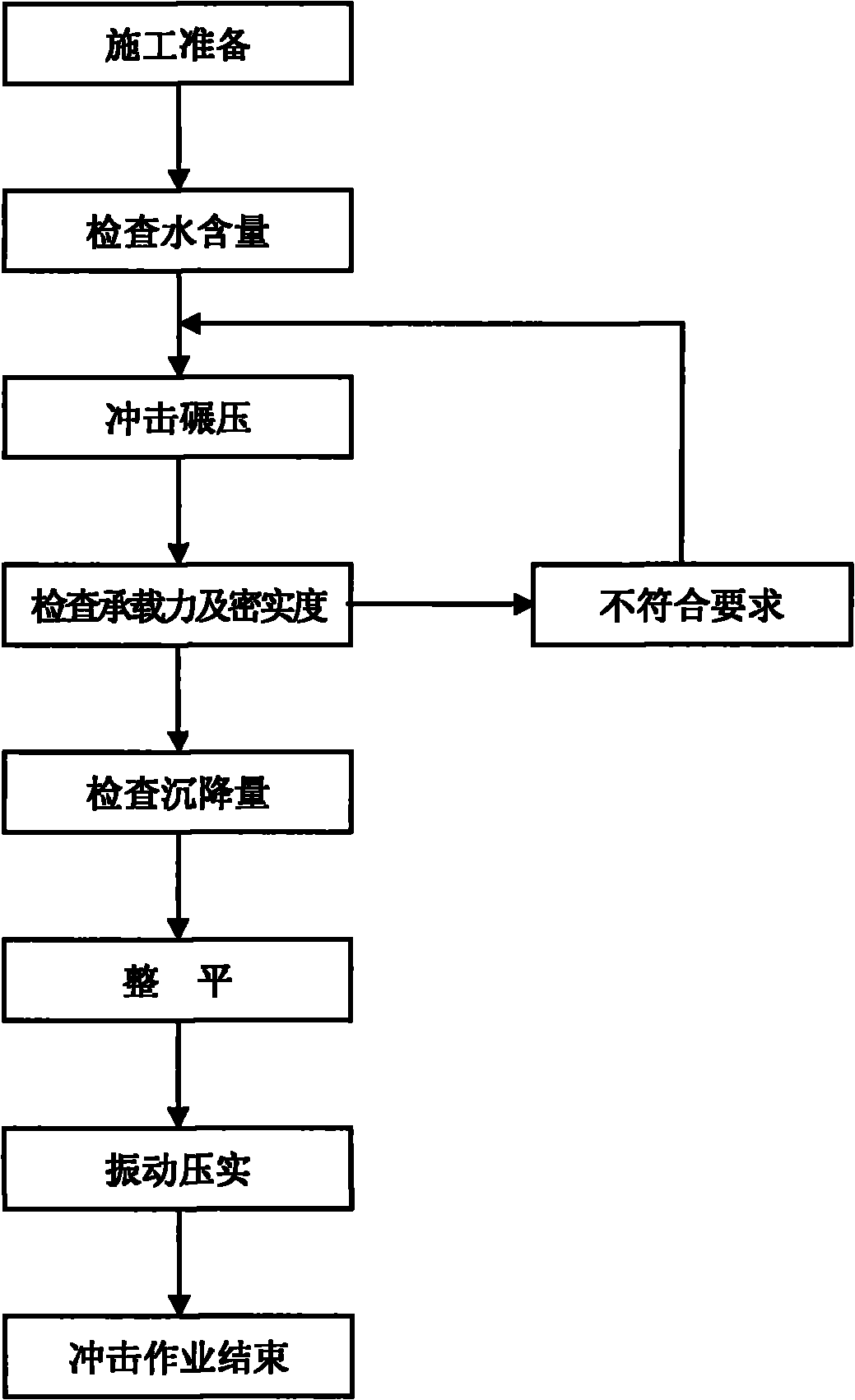

[0024] Introduced with the selected YCT25A triangular impact compactor, such as figure 1 As shown, its construction process is as follows:

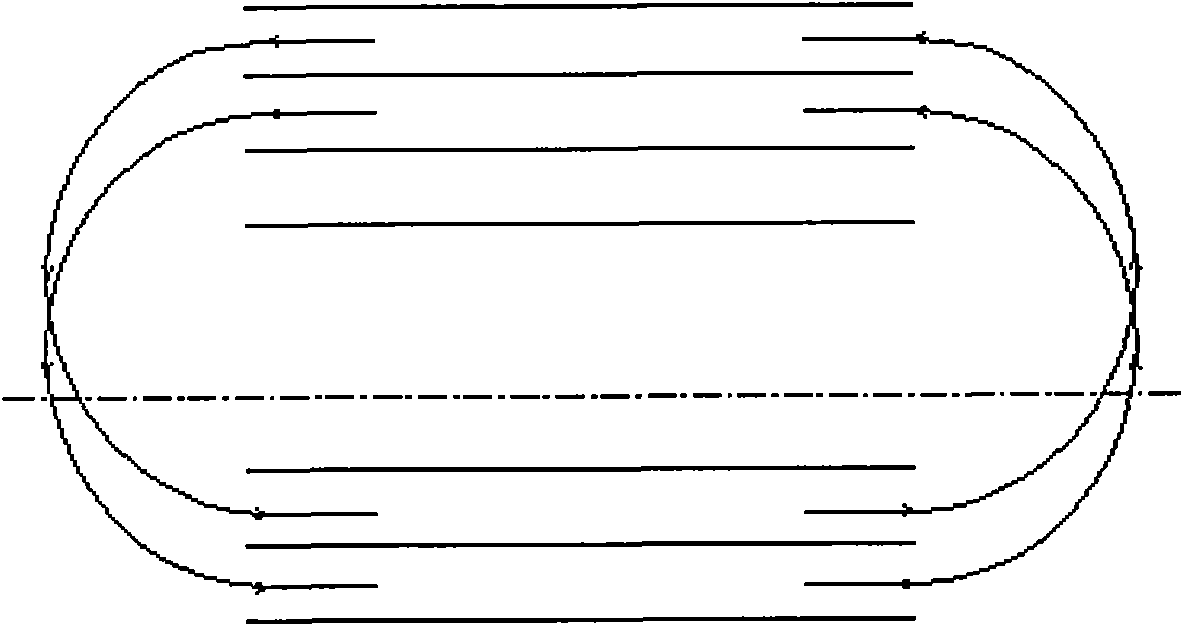

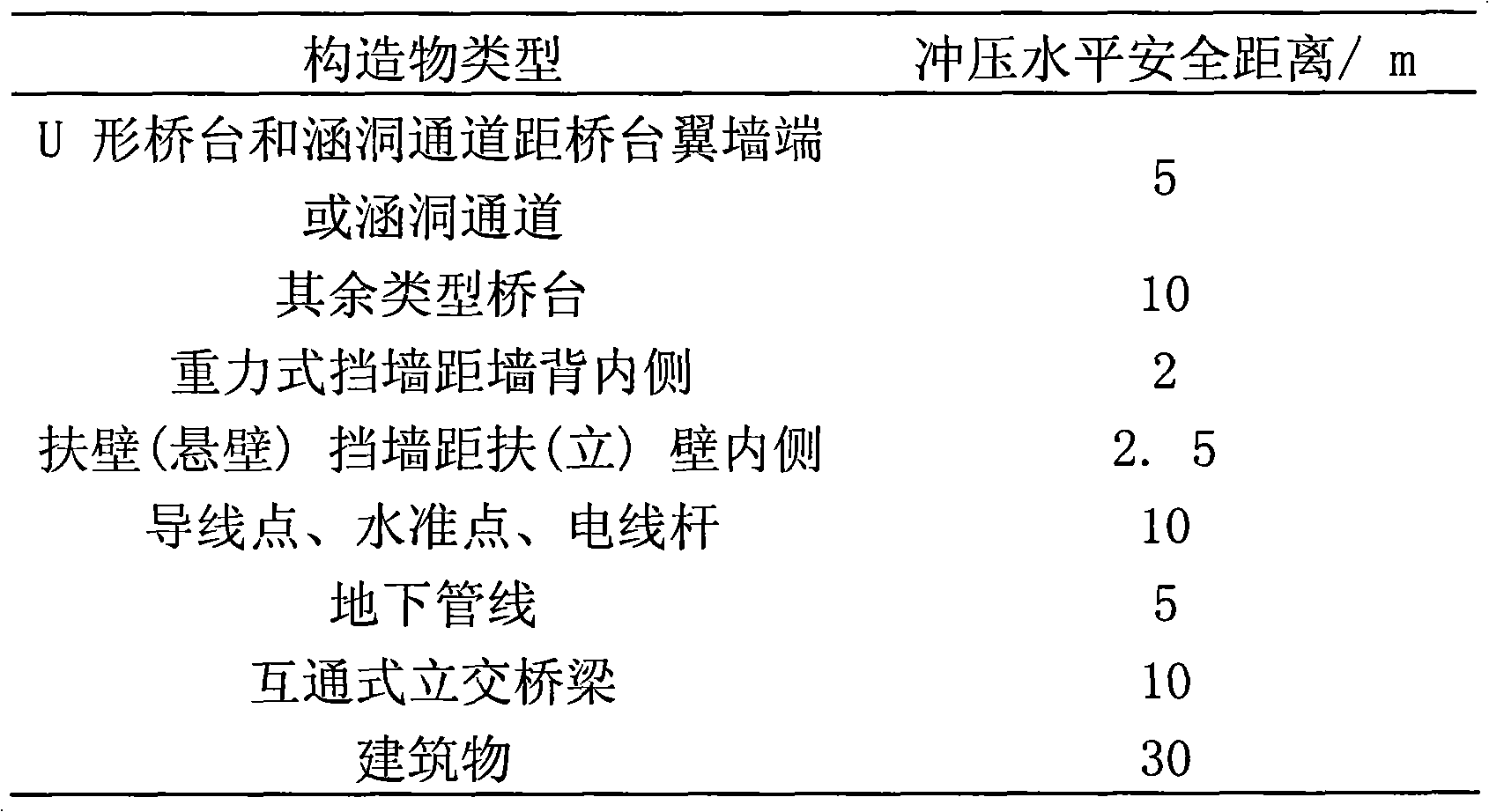

[0025] The construction preparation stage includes (1) compiling the construction plan, formulating the construction methods and technical measures of the main projects; (2) providing technical training to the construction personnel, familiarizing with the design drawings, and making technical disclosure; (3) carrying out measurement and lofting in the impact and rolling test section ;Placing the centerline piles and side piles of the line, in order to ensure that the edge base of the subgrade is fully compacted, each side is widened by 1-2m, and the scope of scouring and rolling is marked with a lime line, and clearly marked with a small red flag, so that the driver can identify it; ( 4) According to the avoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com