Machine-made sand and aeolian sand co-doped ultra-high performance concrete and preparation method thereof

An ultra-high performance, machine-made sand technology, applied in climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of high stone powder content, large fineness modulus, irregular shape, etc. Cost, good performance, effect of improving flow properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

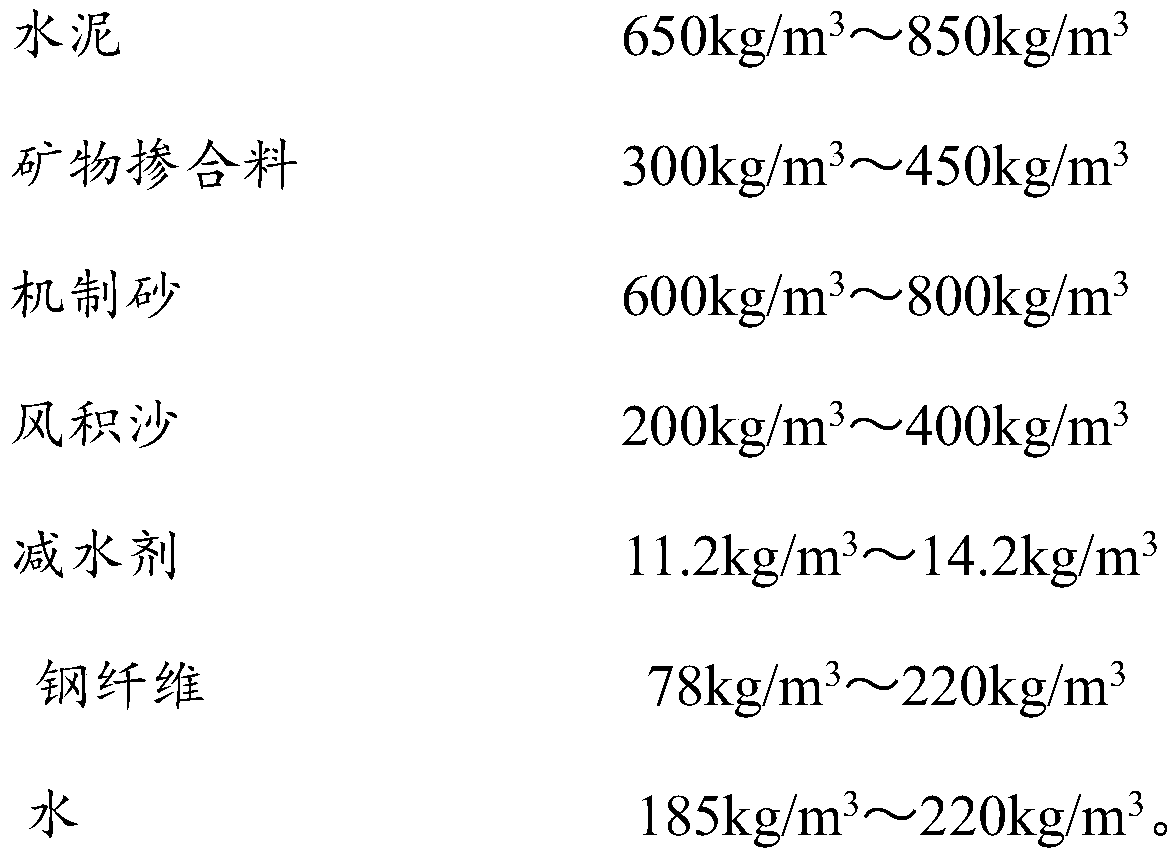

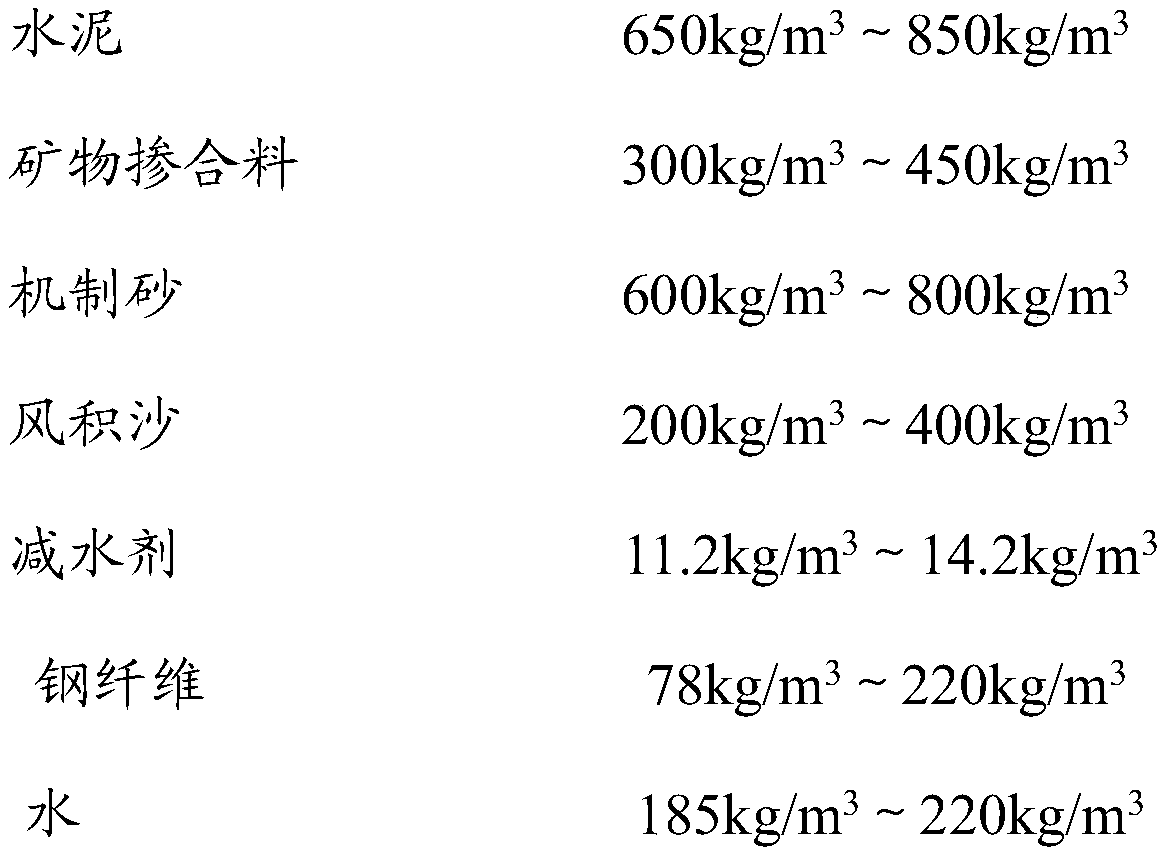

[0030] The ultra-high performance concrete mixed with machine-made sand and aeolian sand prepared in this example has the ratio of raw materials as shown in Table 1:

[0031] Table 1 Ultra-high performance concrete mixed with machine-made sand and aeolian sand (kg / m 3 )

[0032] cement mineral admixture Machine-made sand Aeolian sand Superplasticizer steel fiber water 700 400 800 200 13.7 150 198

[0033] (1) As shown in Table 1, weigh 700 parts by weight of cement, 400 parts by weight of mineral admixture, 800 parts by weight of machine-made sand, 200 parts by weight of aeolian sand, 150 parts by weight of steel fiber, 13.7 parts by weight of water reducing agent and 198 parts by weight of water;

[0034] (2) Stir the cement, mineral admixture, machine-made sand and aeolian sand, steel fiber and water reducer evenly in a vertical planetary forced mixer for 3 minutes;

[0035] (3) Add all the water and stir for 4 minutes. After the concret...

Embodiment 2

[0039] The ultra-high performance concrete mixed with machine-made sand and aeolian sand prepared in this example has the ratio of raw materials as shown in Table 2:

[0040] Table 2 Ultra-high performance concrete mixed with machine-made sand and aeolian sand (kg / m 3 )

[0041] cement mineral admixture Machine-made sand Aeolian sand Superplasticizer steel fiber water 850 300 600 300 12.2 200 205

[0042] (1) As shown in Table 2, weigh 850 parts by weight of cement, 300 parts by weight of mineral admixture, 600 parts by weight of machine-made sand, 300 parts by weight of aeolian sand, 200 parts by weight of steel fiber, 12.2 parts by weight of water reducing agent and 205 parts by weight of water;

[0043] (2) Stir the cement, mineral admixture, machine-made sand and aeolian sand, steel fiber and water reducer evenly in a vertical planetary forced mixer for 3 minutes;

[0044] (3) Add all the water and stir for 4 minutes. After the concret...

Embodiment 3

[0048] The ultra-high performance concrete mixed with machine-made sand and aeolian sand prepared in this example has the ratio of raw materials as shown in Table 3:

[0049] Table 3 Ultra-high performance concrete mixed with machine-made sand and aeolian sand (kg / m 3 )

[0050] cement mineral admixture Machine-made sand Aeolian sand Superplasticizer steel fiber water 750 350 700 250 13.2 200 193

[0051] (1) As shown in Table 3, weigh 750 parts by weight of cement, 350 parts by weight of mineral admixture, 700 parts by weight of machine-made sand, 250 parts by weight of aeolian sand, 200 parts by weight of steel fiber, 13.2 parts by weight of water reducing agent and 193 parts by weight of water;

[0052] (2) Stir cement, mineral admixture, fine aggregate, aeolian sand, steel fiber and water reducer evenly in a vertical shaft planetary forced mixer for 3 minutes;

[0053] (3) Add all the water and stir for 4 minutes. After the concrete is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com