Preparation method of lanthanum trioxide and battery cathode material coated with lanthanum trioxide

A technology of dilanthanum trioxide and coating layer, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor cycle stability of ternary positive electrode modified materials, achieve good stability and cycle performance, and inhibit corrosion function, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

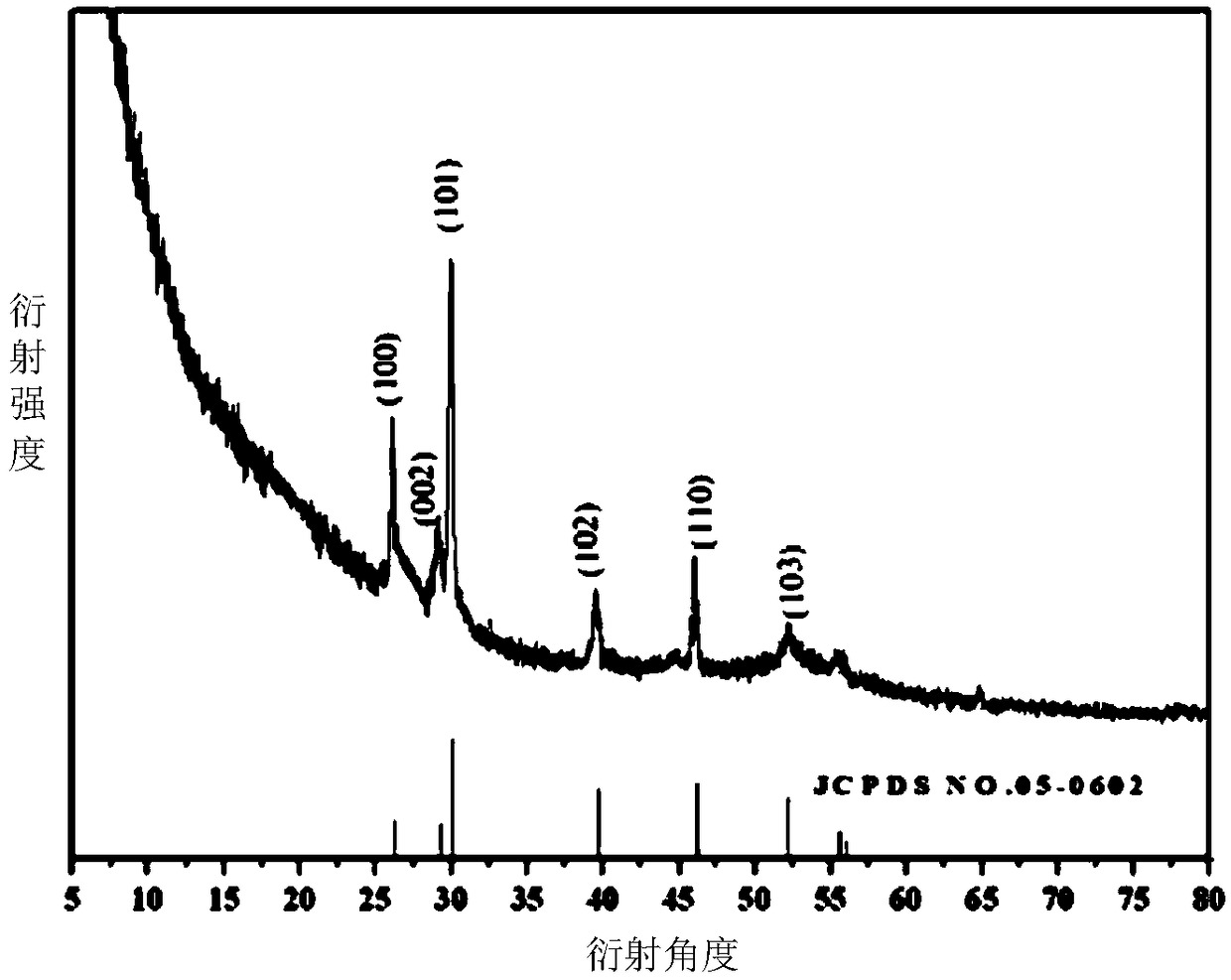

[0051] Weigh 1.0823g of lanthanum nitrate and fully dissolve to obtain A solution; weigh 1.15g of urea and fully dissolve to obtain B solution; add the B solution dropwise to the A solution, stir while adding, and keep the water bath The temperature is 80°C; start timing when all the B solution is added to the A solution, vigorously stir the mixture of the A solution and the B solution, and react at a constant temperature for 12 hours to obtain the C solution; filter the C solution Obtain a precipitate, wash and collect the precipitate, and dry the precipitate at room temperature to obtain a lanthanum hydroxide precursor; place the lanthanum hydroxide precursor at 800°C at a heating rate of 2°C / min and 2°C / min After 5 hours of heat treatment at a cooling rate of min, dilanthanum trioxide can be obtained.

Embodiment 2

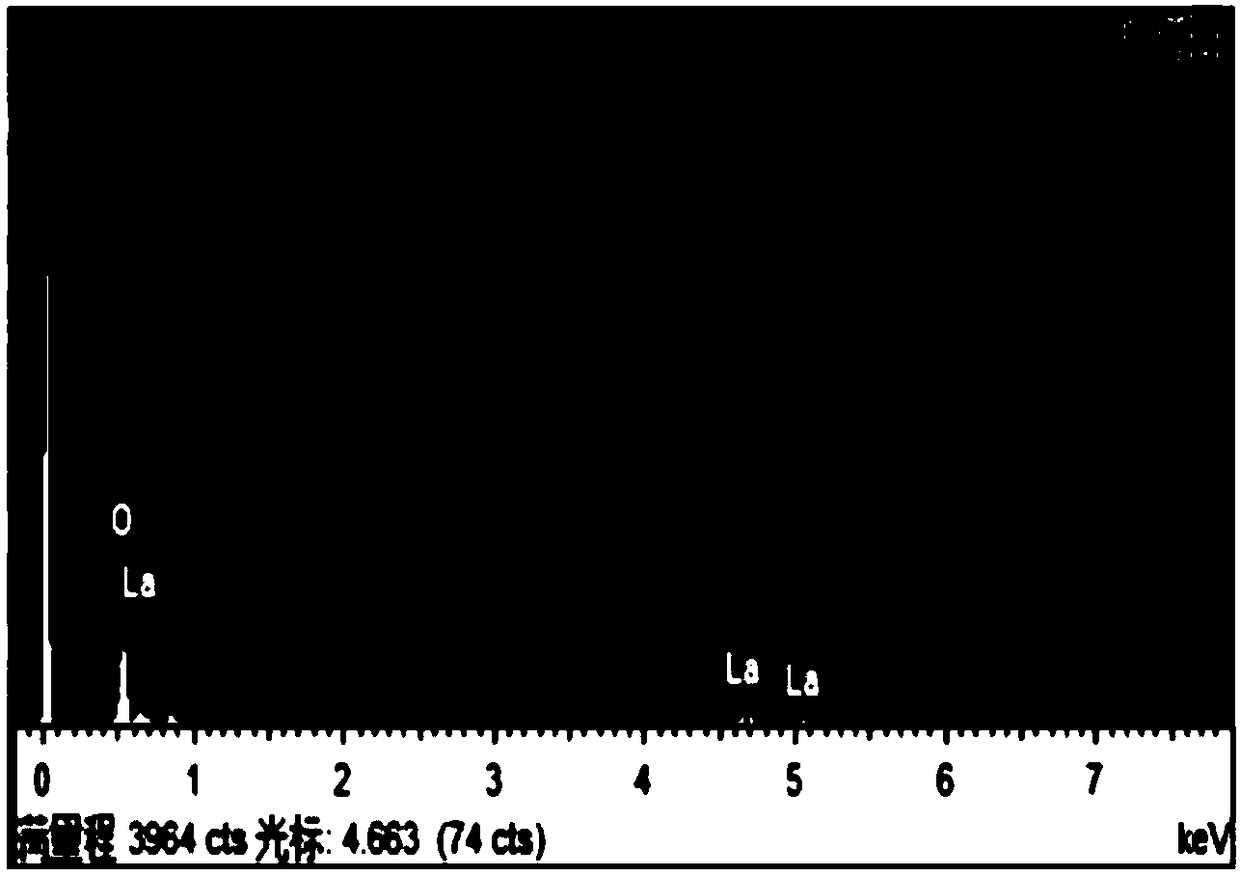

[0052] Embodiment 2 (1) takes by weighing an appropriate amount of pure phase ternary lithium ion battery cathode material LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 ,

[0053]Add it into ethanol, disperse evenly, then add 1.0823g of lanthanum nitrate to it, so that the lanthanum nitrate is completely dissolved, and obtain the A mixed solution;

[0054] (2) Weigh 1.1523g of urea, add it to 50ml of ethanol, and ultrasonically dissolve it to obtain solution B, add solution B dropwise to the mixed solution of A, stir while adding, and keep the temperature of the water bath at 80°C; start timing when all the B solution is added to the A mixture, vigorously stir the mixture of the A mixture and the B solution, and react at a constant temperature for 12 hours to obtain the C mixture;

[0055] (3) The C mixture is filtered to obtain a precipitate, washed, collected, and dried at room temperature to obtain lanthanum hydroxide-coated LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 ;

[0056] (4) LiNi coated with ...

Embodiment 3

[0058] (1) Weigh an appropriate amount of pure phase ternary lithium-ion battery cathode material LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 , was added to ethanol, dispersed evenly, and then 1.08g of lanthanum acetate was added thereto to completely dissolve the lanthanum acetate to obtain a mixed solution of A;

[0059] (2) Weigh 1.54g of urea, add it to 50ml of ethanol, and ultrasonically dissolve it to obtain solution B, add solution B dropwise to the mixed solution of A, stir while adding, and keep the temperature of the water bath at 80°C; start timing when all the B solution is added to the A mixture, vigorously stir the mixture of the A mixture and the B solution, and react at a constant temperature for 12 hours to obtain the C mixture;

[0060] (3) The C mixture is filtered to obtain a precipitate, washed, collected, and dried at room temperature to obtain lanthanum hydroxide-coated LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 ;

[0061] (4) LiNi coated with the lanthanum hydroxide 1 / 3 co 1 / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com