Wire type heating wire device

A technology of heating wires and wires, applied in the direction of heating element materials, heating element shapes, etc., can solve problems such as uneconomical, inability to form a line short circuit prevention circuit, failure of the temperature control part, etc., and achieve the effect of preventing smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

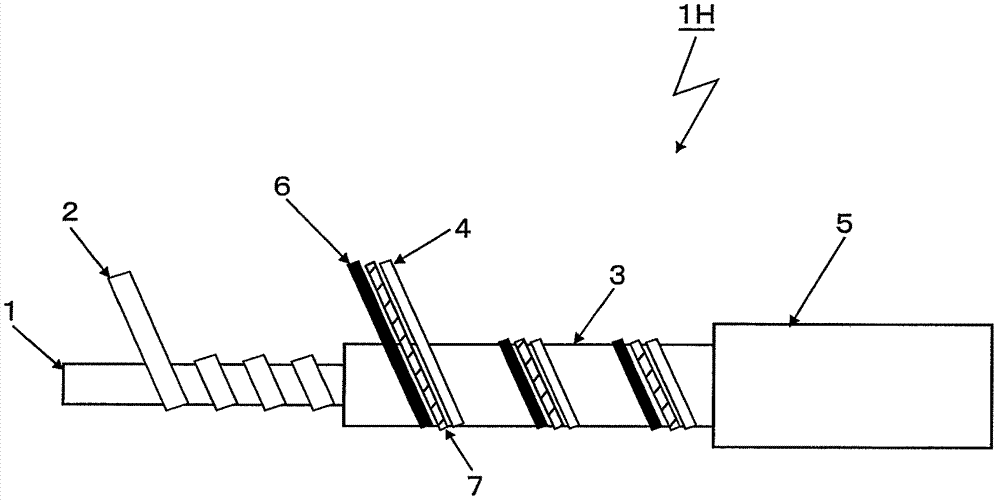

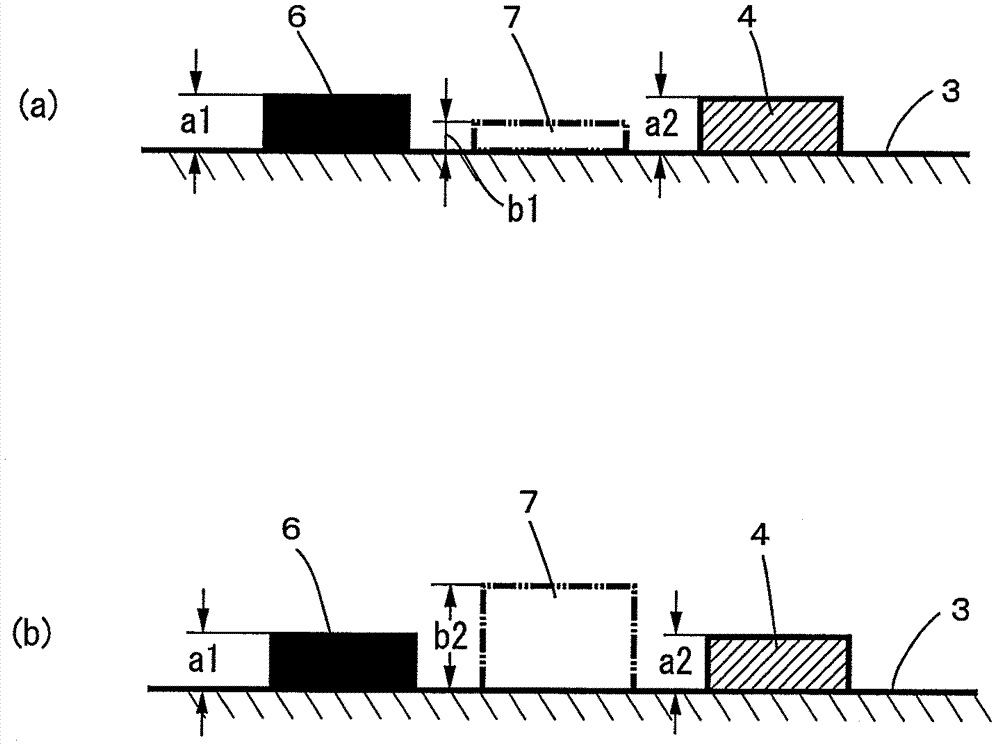

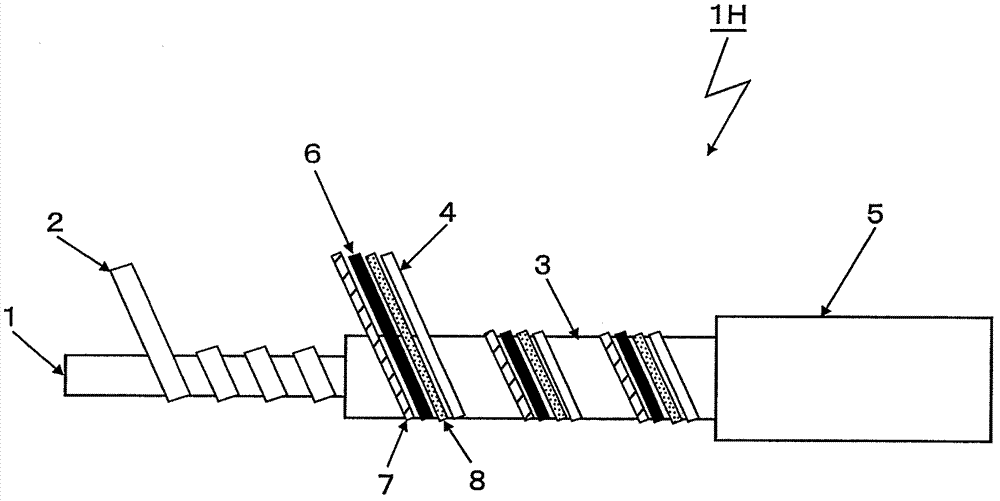

[0100] Embodiments of the electric heating wire according to the present invention will be described in detail below with reference to the drawings and the like. In addition, this invention is not limited to the following unless it deviates from the summary. Figure 1A One end of the wire-shaped heating wire 1H according to the embodiment of the present invention is shown, and the insulating coating layer, the polymer layer, and the like are partially omitted.

[0101] The wire-shaped heating wire 1H is composed of: a winding core 1 of fiber bundles such as glass fibers or polyester fibers; a heating wire 2 formed by helically winding a rectangular conductor of copper or copper alloy around the outer periphery of the winding core 1; A polymer layer 3 formed by extruding a thermosensitive polymer resin on the outer periphery of the heating wire 2; At least one insulated wire 7 between the wires; an insulating coating layer 5 formed by extruding polyvinyl chloride or the like o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com