Iron catalyst containing cobalt auxiliary agent for Fischer-Tropsch synthesis reaction and preparation method thereof

An iron catalyst, Fischer-Tropsch synthesis technology, applied in the direction of catalyst activation/preparation, liquid hydrocarbon mixture preparation, chemical instruments and methods, etc., can solve the problems of large catalyst consumption, large hydrogen consumption, low specific surface area, etc., and achieve excellent selection properties, easy reduction, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take Co(NO 3 ) 2 ·6H 2 0.71g (Co) / L impregnation solution was prepared with 10.0g of O crystal. Take 200g of the catalyst A described in Example 1, add 200g of the above-mentioned impregnation solution evenly to make it just completely soak the catalyst A, place it for 2h and gently stir it to make it uniformly impregnated, after drying in an oven at 110°C, put it into a laboratory rotary roaster, Baking at 350°C for 8 hours. The catalyst contains Co:Fe=0.05%, which is counted as catalyst B. The specific surface area of catalyst B is 174m 2 / g.

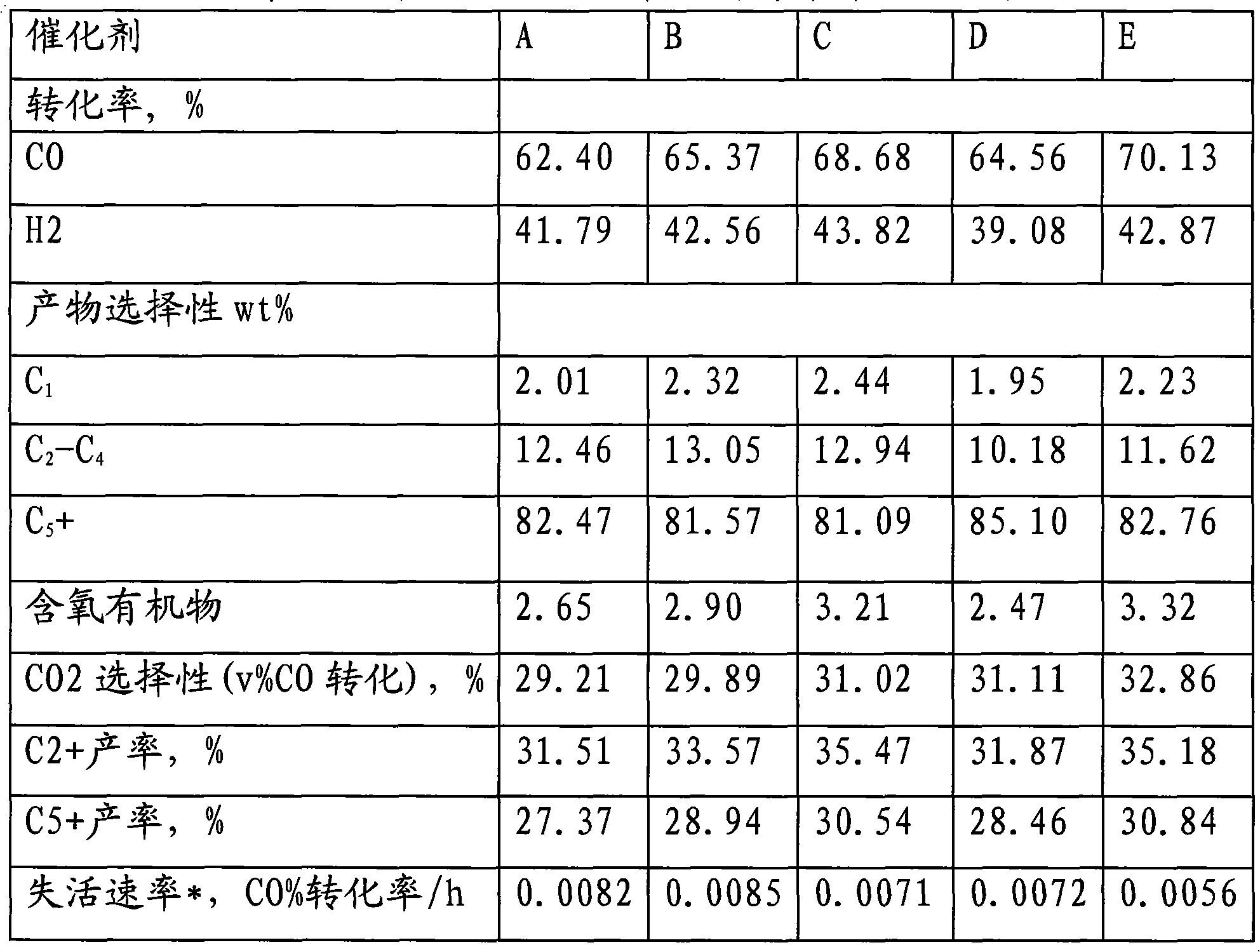

[0034] Table 1 lists the process conditions and corresponding results obtained by evaluating catalyst samples for fixed-bed reactions.

Embodiment 2

[0036] Take Co(NO 3 ) 2 ·6H 2 10.0 g of O crystals was used to prepare a 1.43 g / L impregnation solution. Take 200g of the catalyst A described in Example 1, add 200g of the above-mentioned impregnation solution evenly to make it just completely soak the catalyst A, place it for 2h and gently stir it to make it uniformly impregnated, after drying in an oven at 110°C, put it into a laboratory rotary roaster, Baking at 350°C for 8 hours. The catalyst contains Co:Fe = 0.10%, which is counted as catalyst C. The specific surface area of catalyst C is 172m 2 / g.

[0037] Table 1 lists the process conditions and corresponding results obtained by evaluating catalyst samples for fixed-bed reactions.

Embodiment 3

[0043] Take Co(NO 3 ) 2 ·6H 2 15.0 g of O crystals was used to prepare 3.30 g (Co) / L impregnation solution. Take 250g of the catalyst D described in Example 4, add 250g of the above-mentioned impregnating solution evenly to make it just completely soak into the catalyst A, place it for 3h and gently stir it to make it uniformly impregnated, after drying in an oven at 110°C, put it into a laboratory rotary roaster, Baking at 380°C for 2 hours. The catalyst contains Co:Fe=0.23%, which is counted as catalyst E. The specific surface area of the catalyst is 180m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com