Catalyst and applications in C11<+> heavy aromatic hydrocarbon lightening reactions

A technology for lightening heavy aromatics and catalysts. It is applied in the direction of catalysts, molecular sieve catalysts, and carbon compound catalysts. It can solve the problems of inability to process full fractions, catalysts are not resistant to sulfur, and the purity of aromatic products is not high, so as to suppress excessive hydrogenation. The effect of reaction and strong anti-coking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

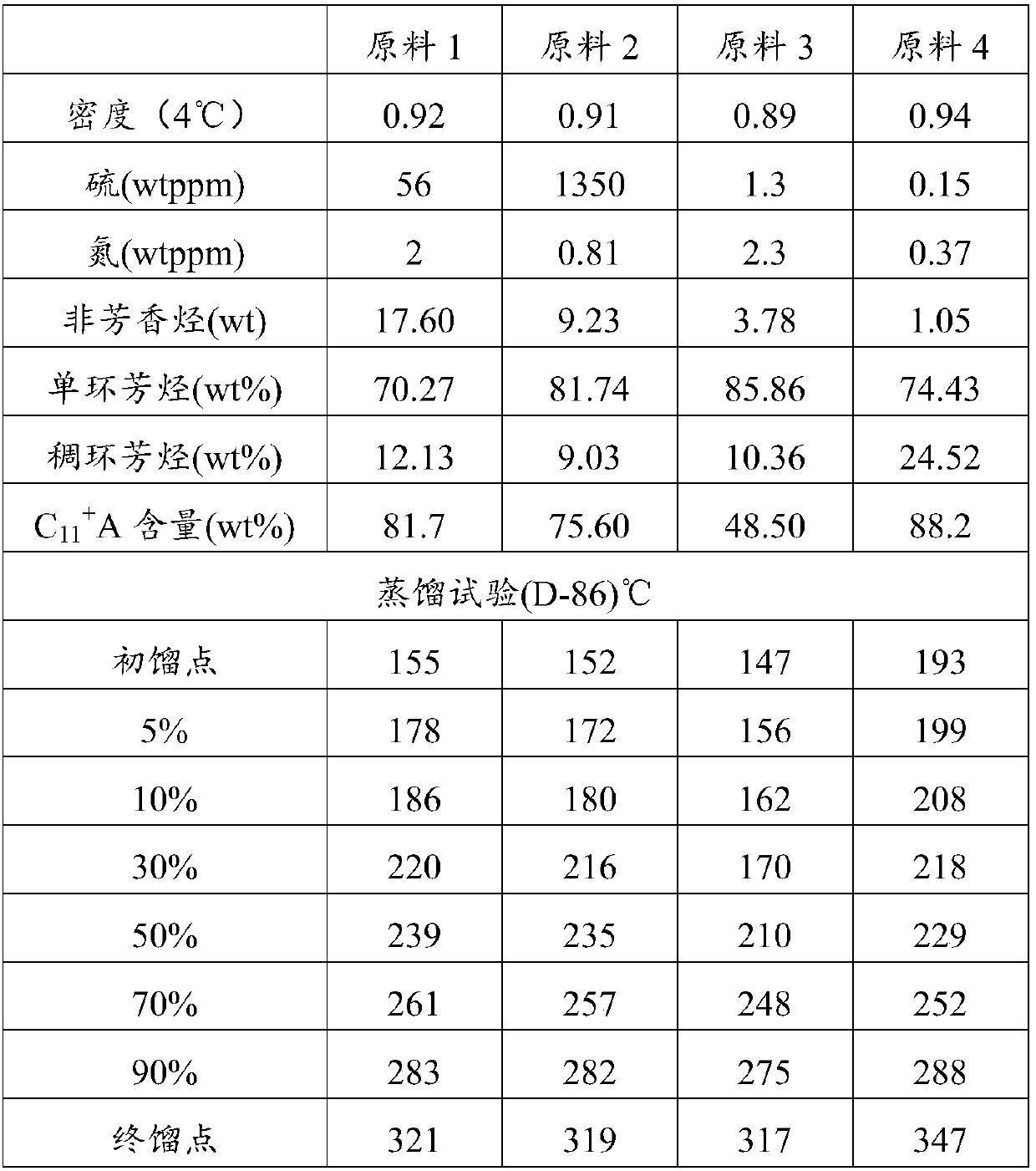

[0075] After mixing hydrogen-type zeolite beta (SAR=25) with a particle size of 60-80nm and pseudo-boehmite, kneading, extruding, drying at 120°C, and roasting in an air atmosphere at 550°C for 4 hours, the desired Catalyst carrier. Prepare a bimetallic solution with tetraammineplatinum chloride and ammonium molybdate, impregnate the catalyst carrier by an equal-volume impregnation method, dry at 120°C, and then bake in an air atmosphere at 500°C for 2 hours to obtain a catalyst precursor. The catalyst precursor is reduced to 450°C under the condition of hydrogen, injected with carbon disulfide sulfurizing agent and vulcanized for 4 hours to obtain the desired lightweight catalyst C1. Its composition is: 0.10 parts of Pt-4.2 parts of MoO 2 -16.8 MoOs 3 -0.9 MoS 2 / 55 parts of beta zeolite - 23 parts of Al 2 o 3 .

[0076] The raw materials and reaction conditions are the same as [Comparative Example 1]. After 24 hours of stable operation, sampling analysis showed that t...

Embodiment 2

[0078] Hydrogen type beta zeolite (SAR=ratio 40) with a particle size of 200-240nm is fully mixed with titanium oxide powder and pseudo-boehmite, kneaded, extruded, dried at 120°C, and then roasted in an air atmosphere of 550°C for 4 hours, the desired catalyst carrier is obtained. A bimetallic solution was prepared with cobalt nitrate and ammonium tungstate, the catalyst carrier was impregnated by an equal volume impregnation method, dried at 120°C and then calcined in an air atmosphere at 500°C for 2 hours to obtain a catalyst precursor. The catalyst precursor was reduced to 450°C under hydrogen, injected into dimethyl disulfide and vulcanized for 4 hours to obtain the desired lightweight catalyst C2. Its composition is: 4 parts of Co-10.2 parts of WO 2 -11.9 WOs 3 -1.2 copies of WS 2 / 52 parts of beta zeolite - 6 parts of Al 2 o 3 -14.7 parts of TiO 2 .

[0079] The raw materials and reaction conditions are the same as [Comparative Example 1]. After 24 hours of stab...

Embodiment 3

[0081] Hydrogen-type mordenite (SAR=16) with a particle size of 160-180nm is fully mixed with SIRAL20 amorphous silica-alumina and pseudo-boehmite, kneaded, extruded, dried at 120°C, and then calcined in an air atmosphere at 550°C for 4 hours, the desired catalyst carrier is obtained. A bimetallic solution was prepared with chloroiridic acid and ammonium molybdate, the catalyst carrier was impregnated by an equal volume impregnation method, dried at 120°C and then calcined in an air atmosphere at 500°C for 2 hours to obtain a catalyst precursor. The catalyst precursor is reduced to 450°C under the condition of hydrogen, and injected into carbon disulfide curing agent for sulfidation for 4 hours to obtain the desired lightweight catalyst C3. Its composition is: 0.5 parts of Ir-8.5 parts of MoO 2 -13.5 MoOs 3 -1.7 MoS 2 / 53 parts of mordenite-18 parts of Al 2 o 3 -4.8 parts of SiO 2 .

[0082] The raw materials and reaction conditions are the same as [Comparative Example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com