PtX-Fe-ZSM-5 molecular sieve catalyst for ammine selective catalytic oxidation

A catalytic oxidation and catalyst technology, applied in molecular sieve catalysts, physical/chemical process catalysts, separation methods, etc., can solve the problems of inability to adapt to working conditions, poor poisoning ability, poor low temperature activity, etc., and achieve superior sulfur resistance and convenience. The effect of simple operation and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Get 100g H-ZSM-5 powder carrier (specific surface area: 335m 2 / g), slowly poured into the aqueous solution of 400ml0.25mol / l ferrous chloride under the condition of constant stirring. Stirred by a magnetic stirrer, after airtight exchange in a water bath at 90°C for 1 hour, wash with deionized water several times, filter, and dry at 100°C overnight. Grind the dried filtrate, and slowly pour it into 200ml of 0.5mol / l ferrous chloride aqueous solution under continuous stirring. Stirred by a magnetic stirrer, after airtight exchange in a water bath at 90°C for 2 hours, wash with deionized water several times, filter, and dry at 100°C overnight. The dried catalyst was heated from room temperature to 550° C. in an air atmosphere at a heating rate of 5° C. / min, and calcined at 550° C. for 3 hours. The 20-40 mesh particles were sieved for later use, and the Fe-ZSM-5 catalyst A of Example 1 was obtained.

Embodiment 2

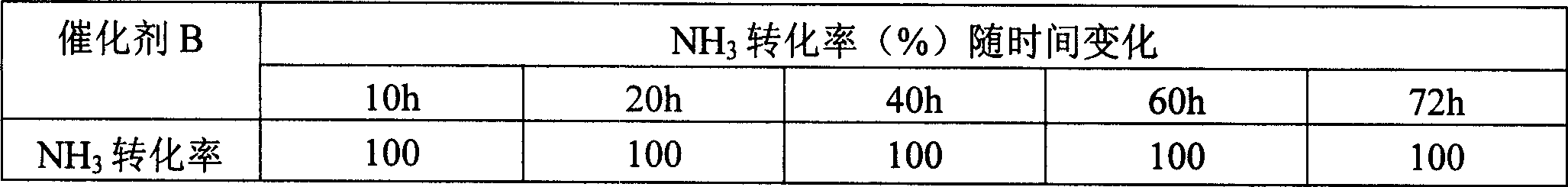

[0018] Get the catalyst A of 100g embodiment 1, slowly pour into 122ml 0.021035mol / l PtCl under constant stirring 4 in the aqueous solution. After stirring for 1 h, use a rotary evaporator to dry the water at 60°C, and dry at 100°C overnight. The dried catalyst was heated from room temperature to 550° C. in an air atmosphere at a heating rate of 5° C. / min, and calcined at 550° C. for 3 hours. Sieve into 20~40 mesh particles for later use, promptly make the 0.5wt.Pt%-Fe-ZSM-5NH of Example 2 3 Oxidation Catalyst B.

Embodiment 3

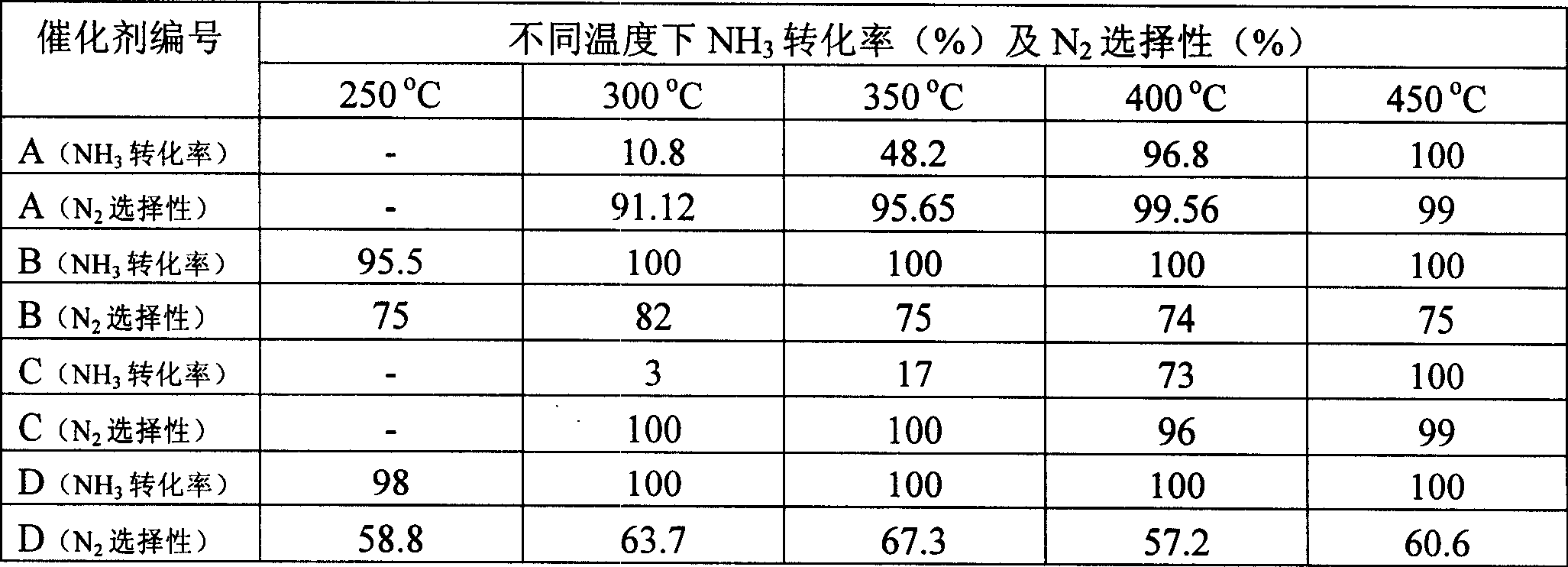

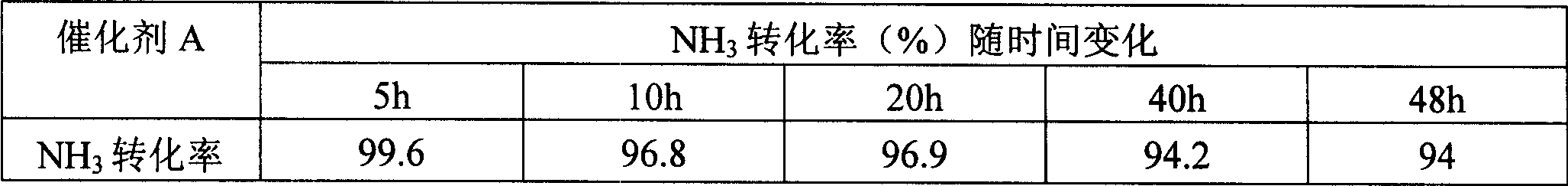

[0024] Embodiment 3: Weigh 0.2g of the catalyst A of embodiment 1 and place it in a tubular fixed-bed reactor to evaluate its catalytic activity under the following conditions. The measurement results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com