High-energy-ball-milling-method SCR molecular sieve catalyst and preparation method thereof

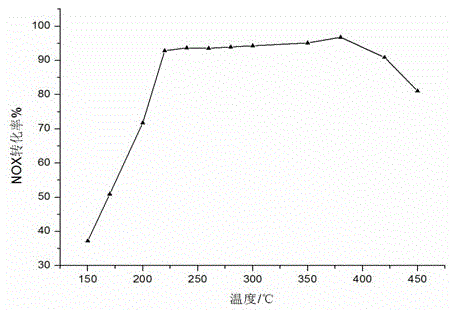

A technology of SCR catalyst and molecular sieve, which is applied in the field of high-energy ball milling SCR molecular sieve catalyst and its preparation, can solve the problems of strict control of reaction conditions, high temperature and pressure of the reactor, and long reaction time of hydrothermal method, and achieves high practical application value. , Improve the effect of sulfur resistance and rich valence state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

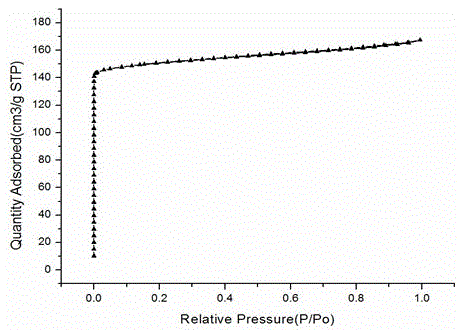

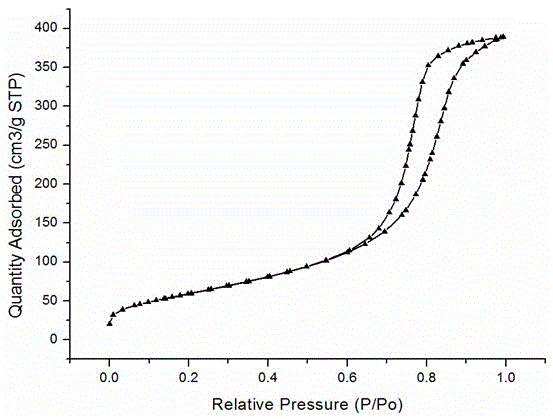

[0036] Weigh 300g of Fe 2 o 3 , add 1200ml of ethanol, add 0.5% cellulose, and ball mill for 2 hours to obtain component A; 100g of cerium oxide, 3000 molecular sieve ZSM-5, add 2000ml of deionized water, add ammonia water to adjust the pH value to 7~8, put it in a ball mill tank, Ball mill for 2 hours; then add component A, ball mill for 2 hours to obtain the iron-based molecular sieve SCR catalyst raw material, let it stand for 1 hour, dry at 105°C, sinter at 500°C, and grind to obtain a finished molecular sieve catalyst with a particle size of 2 microns.

Embodiment 2

[0038] Weigh 300g of copper oxide, add 1200ml of ethanol, add 0.5% cellulose, and ball mill for 2 hours to obtain component A; 100g of cerium oxide, 3000 molecular sieve ZSM-5, add 1200ml of deionized water, add ammonia water to adjust the pH value to 7, and place in the ball mill Tank, ball milled for 2 hours; then add component A, ball milled for 2 hours to obtain copper-based molecular sieve SCR catalyst raw material, stand for 1 hour, dry at 105°C, sinter at 450°C, and grind to obtain a finished molecular sieve catalyst with a particle size of 1 micron.

Embodiment 3

[0040] Weigh 300g of copper oxide, 100g of iron oxide, add 1200ml of ethanol, add 0.5% cellulose, and ball mill for 2 hours to obtain component A; 100g of cerium oxide, 50g of lanthanum oxide, 50g of zirconia and 3000 β molecular sieve, add 1000ml of deionized water, Add ammonia water to adjust the pH value to 7.5, put it in a ball mill tank, and mill it for 5 hours; then add component A, ball mill it for 2 hours to obtain a copper-iron-based molecular sieve SCR catalyst raw material, let it stand for 1 hour, dry it at 105°C, sinter at 550°C, and grind it to obtain a particle The finished molecular sieve catalyst with a diameter of 1 micron.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com