Sulfur tolerant catalyst suitable for slurry bed methanation, its preparation method and application

A catalyst and slurry bed technology, which is applied in the field of synthetic methane catalyst and preparation, can solve the problems of easy deactivation and low sulfur tolerance of the catalyst, and achieve the effects of increasing low-temperature activity, good reactivity, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

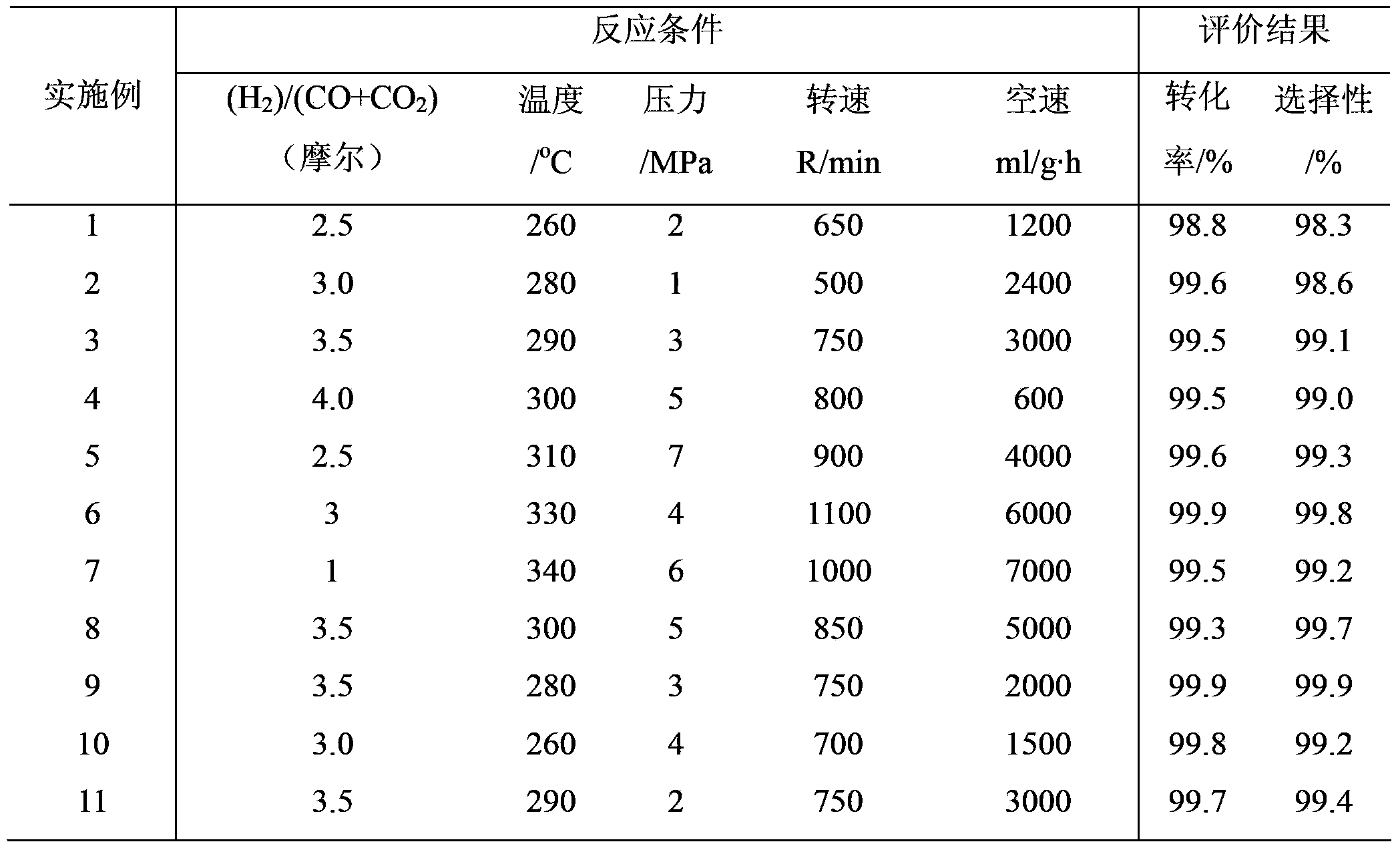

Examples

Embodiment 1

[0029] Carrier pretreatment: 40-60 mesh, specific surface area is 100m 2 / g γ-Al 2 o 3 Calcination at 400°C for 2h; impregnation: at 20°C, stirring speed 60r / min, catalyst composition according to Ni:Mo:γ-Al 2 o 3 The mass percentage of 20%: 15%: 65% preparation. 9.908g of Ni(NO 3 ) 2 ·6H 2 O and 5.816g of Mo(NO 3 ) 3 ·5H 2 O was dissolved in 10ml of water to make a mixed solution, and 6.5g of the calcined carrier γ-Al 2 o 3 Add the above solution to impregnate and stir for 12h, continue to stand for 4h, and then solvent to a viscous solution at 50°C.

[0030] ·Drying and roasting: put the impregnated sample into an oven and dry at 70°C for 12h, grind the dried powder and place it in a muffle furnace and roast at 350°C for 6h to obtain NiO-Mo 2 o 3 / γ-Al 2 o 3 Prebody;

[0031] Hydrogen reduction: NiO-Mo 2 o 3 / γ-Al 2 o 3 The precursor body is ground to 40-60 mesh, and the volume composition is 5%H 2 with 95%N 2 , in a mixed atmosphere with a flow rate of...

Embodiment 2

[0034] Carrier pretreatment: 60-80 mesh, specific surface area is 150m 2 / g SiO 2 Roast at 450°C for 3h;

[0035] Impregnation: at 25°C, stirring speed 30r / min, catalyst composition according to Ce:W:SiO 2 The mass percentage of 10%: 15%: 75% preparation. 3.099g of Ce(NO 3 ) 3 ·6H 2 O and 3.752g of W(NO 3 ) 3 ·5H 2 O was dissolved in 15ml water to make a mixed solution, and 7.5g of the calcined carrier SiO 2 Add the above solution to impregnate and stir for 6h, continue to stand for 12h, and then solvent to a viscous solution at 70°C.

[0036] ·Drying and calcination: put the impregnated sample in an oven and dry at 90°C for 12h, grind the dried powder and place it in a muffle furnace and bake at 400°C for 6h to obtain Ce-W / SiO 2 Prebody.

[0037] Hydrogen reduction: Ce-W / SiO 2 The precursor body is ground to 60-80 mesh, and the volume composition is 10%H 2 with 90%N 2 , in a mixed atmosphere with a flow rate of 110mL / min, using two-stage temperature programming ...

Embodiment 3

[0040] Carrier pretreatment: 80-100 mesh, specific surface area is 200m 2 / g of MgO was roasted at 450°C for 6h;

[0041] Impregnation: at 30°C, the stirring speed is 300r / min, and the catalyst composition is prepared according to the mass percentage of Fe:V:MgO: 2%:0.5%:97.5%. 1.447g of Fe(NO 3 ) 3 9H 2 O and 0.115 g NH 4 VO 3 Dissolve in 20ml of water to make a mixed solution, add 9.75g of roasted carrier MgO into the above solution to impregnate and stir for 36h, continue to stand for 1h, and then solvent to a viscous solution at 80°C.

[0042] ·Drying and roasting: put the impregnated sample in an oven and dry at 100°C for 20h, grind the dried powder and put it in a muffle furnace and roast at 450°C for 6h to obtain the Fe-V / MgO precursor.

[0043] Hydrogen reduction: Grind the Fe-V / MgO precursor to 80-100 mesh, and the volume composition is 15%H 2 with 85%N 2 , in a mixed atmosphere with a flow rate of 130mL / min, using two-stage temperature programming control, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com