Method for improving water resistance and sulfur resistance of manganese-based low-temperature SCR denitration catalyst

A technology of SCR catalyst and denitrification catalyst, which is applied in the field of preparing water-resistant and sulfur-resistant catalysts, can solve problems such as difficult application, and achieve excellent water-resistant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

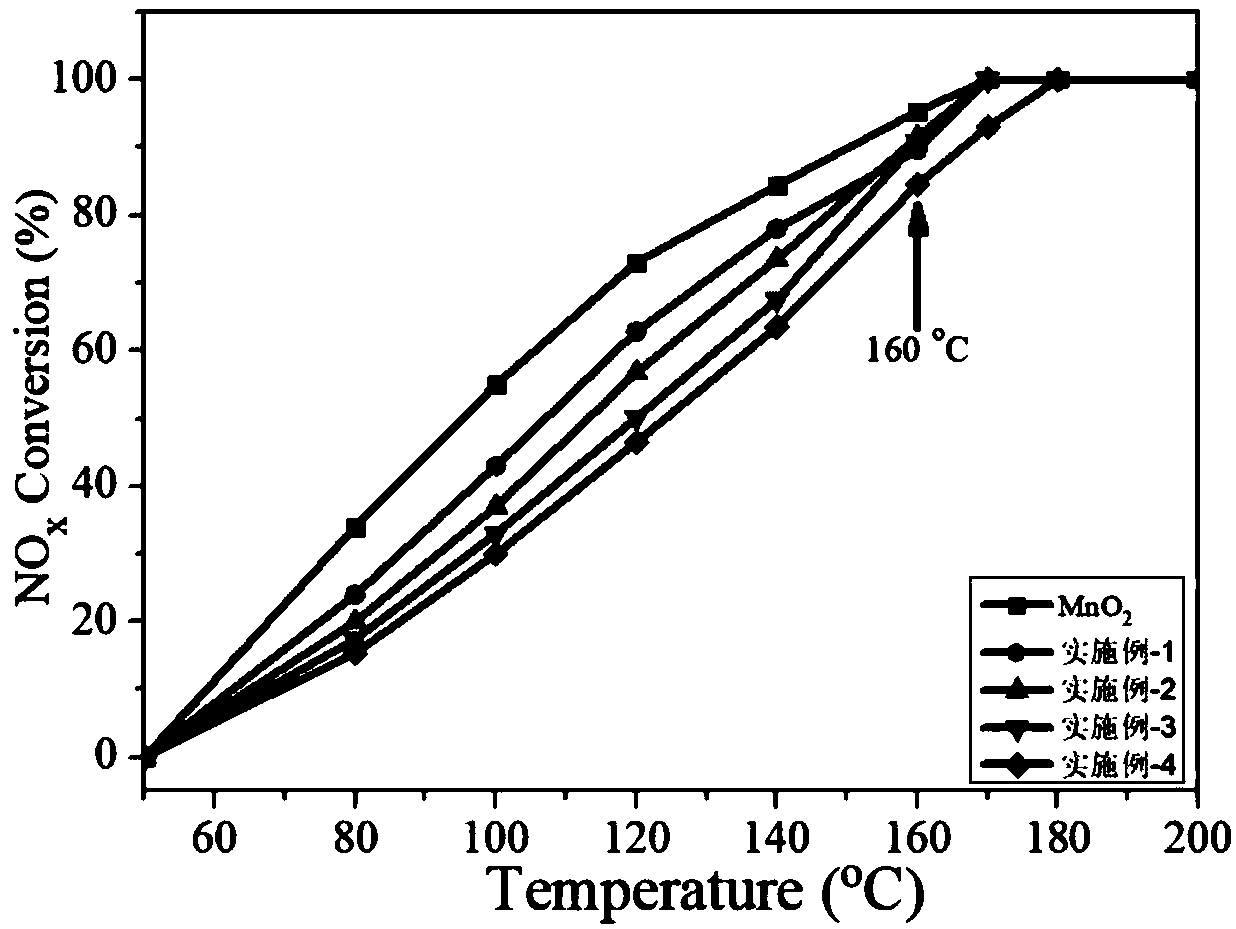

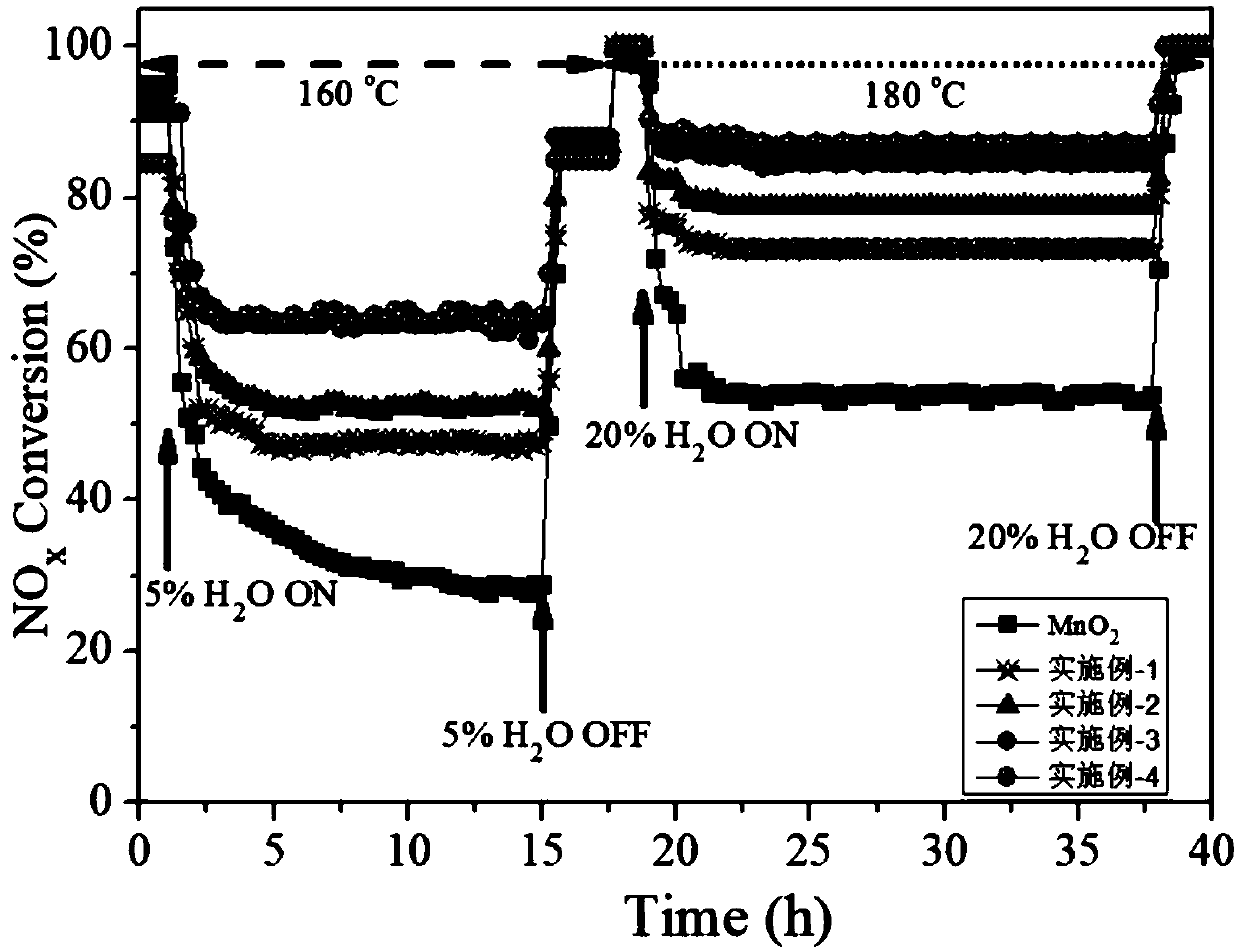

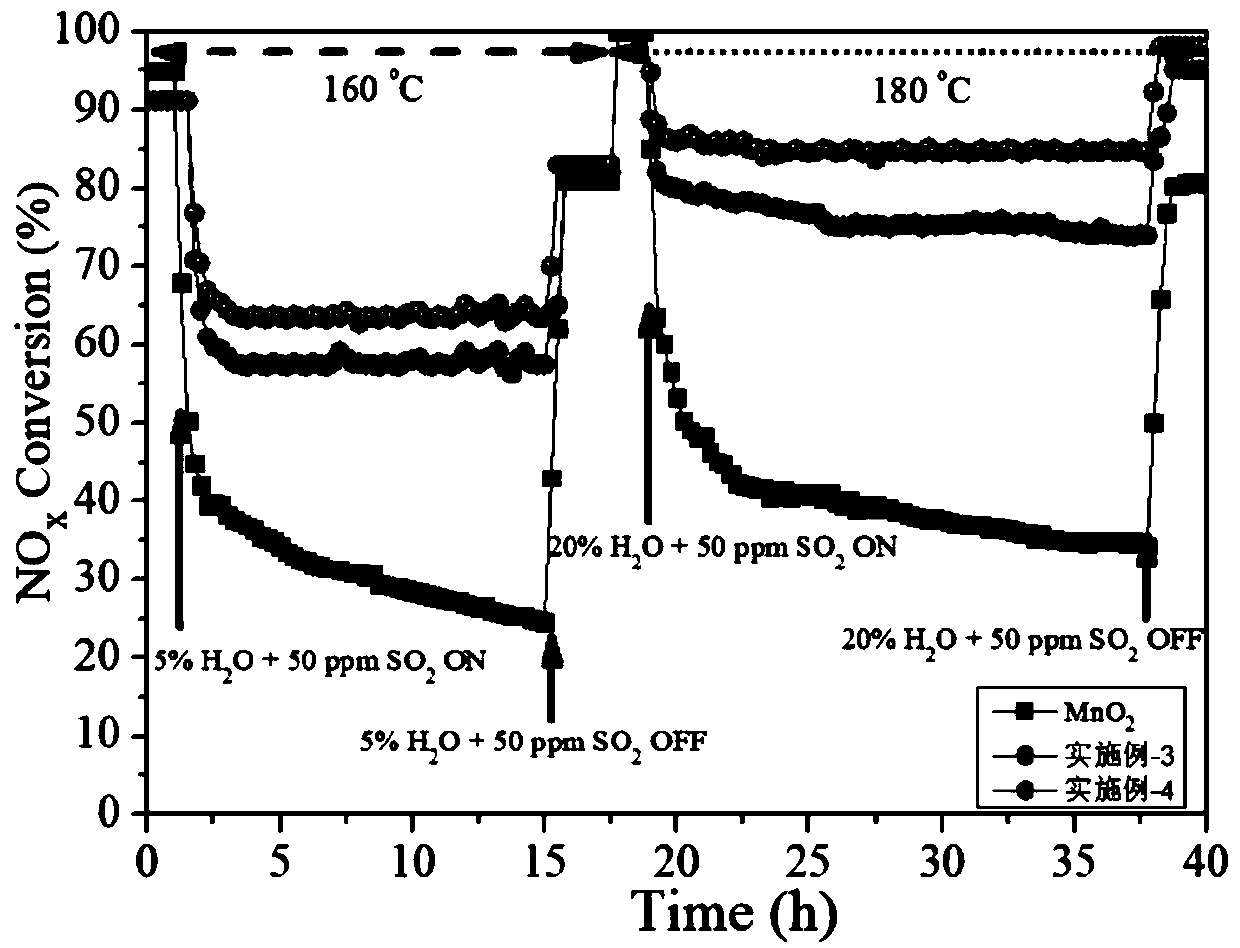

Embodiment 1

[0016] Embodiment 1: 0.25g PTFE is dispersed in the container that 200ml dehydrated alcohol is housed, stirs 2h, adds 4gMnO 2 , stirred at room temperature for 10 hours, filtered, dried in an oven at 120°C, and calcined in a muffle furnace at 200°C for 2 hours to prepare SCR water-resistant and sulfur-resistant catalysts.

Embodiment 2

[0017] Embodiment 2: according to the preparation method of embodiment 1, 0.5g PTFE is dispersed in the container that 200ml dehydrated alcohol is housed, stirs 2h, adds 4g MnO 2 , stirred at room temperature for 10 hours, filtered, dried in an oven at 120°C, and calcined in a muffle furnace at 200°C for 2 hours to prepare SCR water-resistant and sulfur-resistant catalysts.

Embodiment 3

[0018] Embodiment 3: according to the preparation method of embodiment 1, 0.75g PTFE is dispersed in the container that 200ml dehydrated alcohol is housed, stirs 2h, adds 4g MnO 2 , stirred at room temperature for 10 hours, filtered, dried in an oven at 120°C, and calcined in a muffle furnace at 200°C for 2 hours to prepare SCR water-resistant and sulfur-resistant catalysts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com