Ferrotitanium composite oxides catalyst for ammonia selective reduction nitric oxides

A nitrogen oxide, ammonia selective technology, applied in metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical/physical process, etc. problems such as high space velocity conditions, to achieve the effects of superior sulfur resistance, low price and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0016] Prepare a certain concentration of Fe(NO 3 ) 3 solution and TiCl 4 Mix the solution evenly, slowly add ammonia water dropwise to the mixed solution under stirring with a magnetic stirrer, adjust the pH value to 10 to make the precipitation complete, then carry out suction filtration and washing, put the filter cake in an oven and dry overnight at 100°C , and finally roasted in air at 400°C for 6 hours in a muffle furnace, and the prepared catalyst was ground and sieved, and 20-40 mesh was taken for later use, called catalyst A. Other conditions remained unchanged, and the calcination temperature was changed to 500°C, 600°C, and 700°C to prepare catalysts B, C, and D.

Embodiment 5-8

[0018] Prepare a certain concentration of Fe(NO 3 ) 3 solution and Ti(SO 4 ) 2 Mix the solution evenly, slowly add ammonia water dropwise to the mixed solution under stirring with a magnetic stirrer, adjust the pH value to 10 to make the precipitation complete, then carry out suction filtration and washing, put the filter cake in an oven and dry overnight at 100°C , and finally roasted in air at 400°C for 6 hours in a muffle furnace, and the prepared catalyst was ground and sieved, and 20-40 meshes were taken for later use, called catalyst E. Other conditions remained unchanged, and the calcination temperature was changed to 500°C, 600°C, and 700°C to prepare catalysts F, G, and H.

Embodiment 9

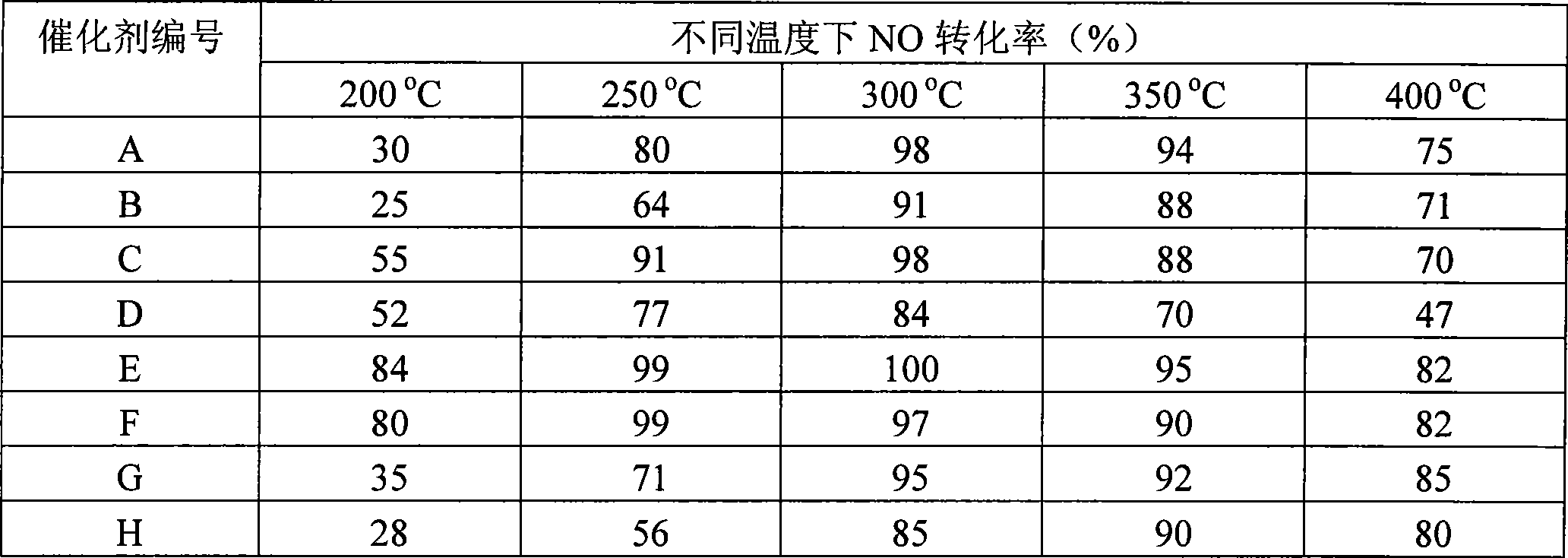

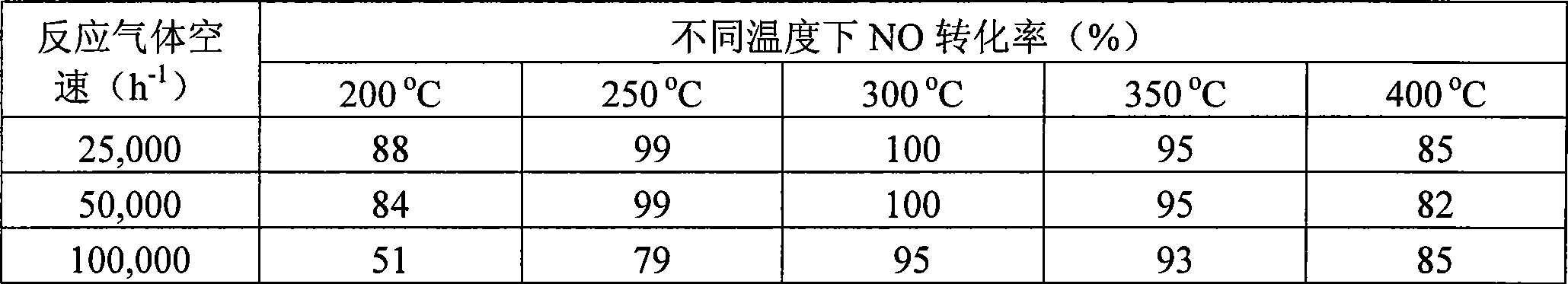

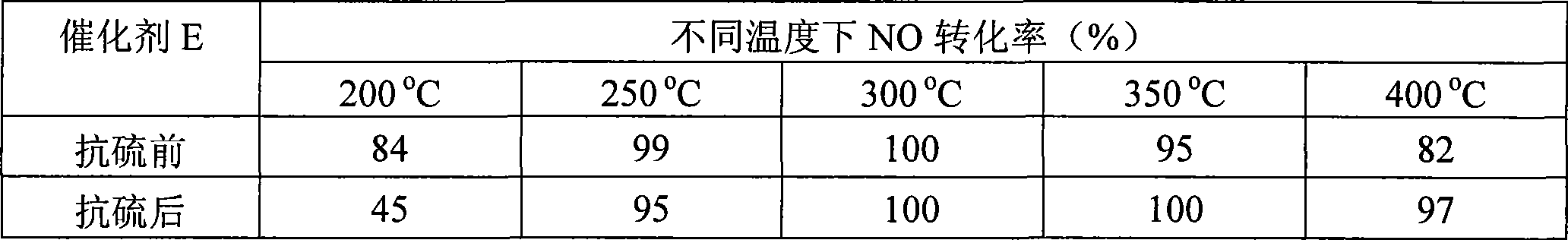

[0020] With the iron-titanium mixed oxide catalyst that embodiment 1-8 makes, carry out NH on self-made miniature fixed-bed reactor 3 Investigation of the Reactivity of Selective Catalytic Reduction of NO. The consumption of catalyst is 0.6ml, and the composition of reaction gas mixture is: [NO]=[NH 3 ]=500ppm, [O 2 ] = 5%, N 2 As a balance gas, the gas space velocity is 50,000h -1 , The reaction temperature is 200-400°C. The reaction results are shown in Table 1.

[0021] Table 1 Evaluation results of catalyst activity

[0022]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com