Denitration catalyst and preparation method thereof

A denitrification catalyst and catalyst technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of single catalyst carrier components, poor anti-poisoning performance, etc., and achieve widened reaction temperature window and high surface energy , improve the effect of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

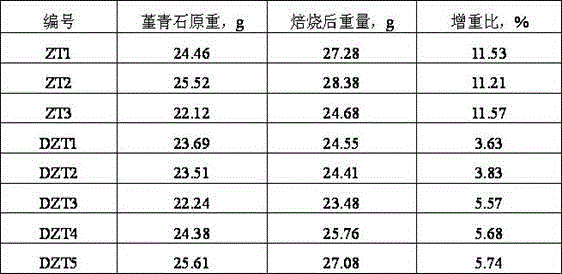

Embodiment 1

[0034] Cordierite pretreatment: completely immerse cordierite honeycomb ceramics in 5wt% nitric acid solution for 1 hour, rinse with deionized water for 3 times after taking it out, put it in an oven at 120°C, and dry it for 10 hours to obtain Surface activated cordierite honeycomb ceramic support.

[0035] Aluminum sol preparation: 20 grams of pseudoboehmite was added to 150 mL of deionized water, and 7 grams of concentrated nitric acid was added dropwise while stirring. After stirring for a certain period of time, heat to 80°C, add nitric acid dropwise until completely peptized, control the pH value of the solution at 2-5, and age for 24 hours to obtain a transparent aluminum sol with a content of 8wt% based on alumina.

[0036] Preparation of silicon-aluminum coating slurry: first mix 90 grams of aluminum sol with 6 grams of fumed silica, add 4 grams of fatty alcohol polyoxyethylene ether (molecular formula is RO(CH 2 CH 2 O) 5 H, where R is C 7 ~C 9 ) after stirring a...

Embodiment 2

[0043] Cordierite pretreatment: with embodiment 1.

[0044] Aluminum sol is commercially available (solid content is 15%, pH is 3-4).

[0045] Preparation of polyvinyl alcohol solution: 9.5 grams of polyvinyl alcohol (molecular formula is (C 2 h 4 O) n ) was dissolved in 91 grams of deionized water, slowly heated to 80°C, and stirred until completely dissolved to obtain a PVA solution with a concentration of 9.45wt%.

[0046] Preparation of silicon-aluminum coating slurry: First, mix 87 grams of aluminum sol and 10 grams of fumed silica evenly, add 3 grams of alkylphenol polyoxyethylene ether (molecular formula is RC 6 h 4 O(CH 2 CH 2 O) n H, where R is C 9 ~C 12 , n is 9~12) After stirring and mixing for 30 minutes, the coating liquid can be obtained.

[0047] Composite coating slurry preparation: add 54 grams of nano-titanium dioxide (50-100nm), 32 grams of ZSM-5 molecular sieve (80-200nm, silicon-aluminum ratio of 25), 17.2 grams of nano-cerium oxide, and add 280m...

Embodiment 3

[0053] Cordierite pretreatment: with embodiment 1.

[0054] Aluminum sol preparation: same as embodiment 1.

[0055] Preparation of silicon-aluminum coating slurry: firstly mix 92 grams of aluminum sol with 4 grams of fumed silica, add 4 grams of secondary octanol polyoxyethylene ether (molecular formula is C 8 h 17 (CH 2 CH 2 O) n H, wherein n is 1-6) After stirring and mixing for 30 minutes, the coating liquid can be obtained.

[0056] Composite coating slurry preparation: 25 grams of nano-titanium dioxide (100-150nm), 5 grams of ZSM-5 molecular sieve (80-200nm, silicon-aluminum ratio of 25), 9.2 grams of nano-zirconia, adding 210ml of carbonic acid solution (0.3mol / In L), after stirring evenly, add 45 grams of aluminum sol to it, use a high-shear dispersing emulsifier (FLUKO FA25 10000rpm) to shear and disperse for 10 minutes, and then add 6.1 grams of 2-octanyl polyoxyethylene ether (molecular formula is C 8 h 17 (CH 2 CH 2 O) n H, wherein n is 1 ~ 6), and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com