Anti-carbon-deposition Ni-based catalyst for hydrogen production by methane steam reforming and preparation method thereof

A methane water vapor, reforming hydrogen production technology, applied in the field of catalysis, can solve the problems of unsatisfactory catalytic activity and stability, and achieve the effects of strong anti-carbon deposition, easy control of conditions, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Ni / La 2 Zr 2 o 7 Particle catalyst, the preparation method is as follows:

[0032] (1) La(NO 3 ) 3 ·6H 2 O, Zr(NO 3 ) 3 ·3H 2 O is dissolved in metered deionized water to form a solution with a concentration of 0.5mol / L;

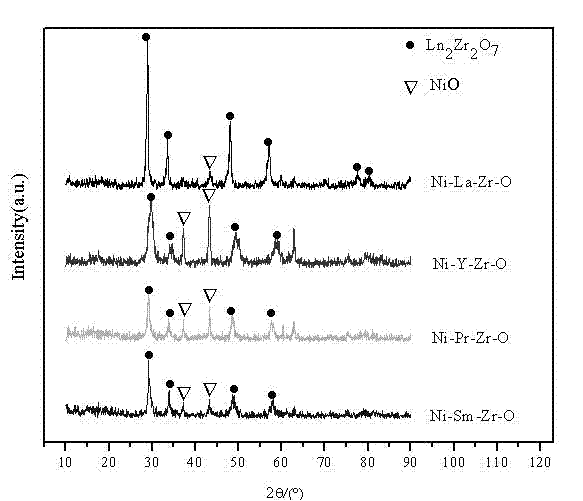

[0033] (2) Dilute the industrial ammonia water with a concentration of 25% to 1 times as a precipitating agent. Under continuous stirring, add the salt solution obtained in (1) dropwise to the above precipitating agent, control the pH=10, and after the precipitation is complete, let it stand at room temperature. After 12 hours, wash with deionized water until the TDS of the filtrate2 Zr 2 o 7 Composite oxide support, characterized by XRD, such as figure 1 As shown, the support has pyrochlore-type structure characteristic diffraction peaks; X-ray diffraction results show that catalysts with pyrochlore-type structures containing different rare earths have been synthesized.

[0034] (3) Ni(NO) with a nickel content of 12% catalyst mass 3 ) ...

Embodiment 2

[0037] Ni / Y 2 Zr 2 o 7 Particle catalyst, the preparation method is as follows:

[0038] (1) Y(NO) with Y:Zr (molar ratio) of 1:1 3 ) 3 ·6H 2 O, Zr(NO 3 ) 3 ·3H 2 O is dissolved in metered deionized water to form a solution with a concentration of 0.5mol / L;

[0039] (2) Dilute the industrial ammonia water with a concentration of 25% to 1 times as a precipitating agent. Under continuous stirring, add the salt solution obtained in (1) dropwise to the above precipitating agent, control the pH=10, and after the precipitation is complete, let it stand at room temperature. After 12 hours, wash with deionized water until the TDS of the filtrate2 Zr 2 o 7 Composite oxide support, characterized by XRD, such as figure 1 As shown, the carrier has pyrochlore-type structure characteristic diffraction peaks;

[0040] (3) Ni(NO) with a nickel content of 12% catalyst mass 3 ) 3 ·6H 2 O was dissolved in metered deionized water, and the prepared carrier was impregnated in metered...

Embodiment 3

[0043] Ni / Pr 2 Zr 2 o 7 Particle catalyst, the preparation method is as follows:

[0044] (1) Pr(NO 3 ) 3 ·6H 2 O, Zr(NO 3 ) 3 ·3H 2 O is dissolved in metered deionized water to form a solution with a concentration of 0.5mol / L;

[0045] (2) Dilute the industrial ammonia water with a concentration of 25% to 1 times as a precipitating agent. Under continuous stirring, add the salt solution obtained in (1) dropwise to the above precipitating agent, control the pH=10, and after the precipitation is complete, let it stand at room temperature. After 12 hours, wash with deionized water until the TDS of the filtrate2 Zr 2 o 7 Composite oxide support, characterized by XRD, such as figure 1 As shown, the carrier has pyrochlore-type structure characteristic diffraction peaks;

[0046] (3) Ni(NO) with a nickel content of 12% catalyst mass 3 ) 3 ·6H 2 O was dissolved in metered deionized water, and the prepared carrier was impregnated in metered nickel salt solution by equal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com