A main and standby equipment intelligent converter

A technology for backup equipment and converters, applied in instruments, simulators, general control systems, etc., can solve problems such as increased labor intensity of workers, untimely equipment switching, economic damage to working equipment, etc., to reduce labor costs and labor intensity of workers. , maintain and prevent equipment aging, and ensure the effect of normal and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate those skilled in the art to better understand the essence of the present invention, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

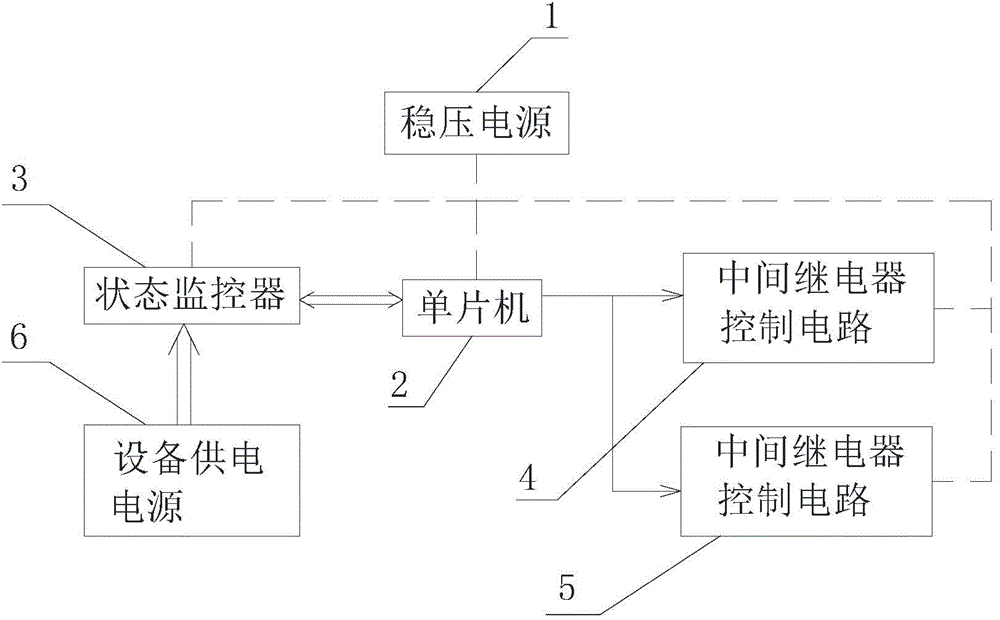

[0029] Such as figure 1 As shown, an intelligent converter for main and backup equipment includes: a regulated power supply 1 , a single chip microcomputer 2 , a state monitor 3 , an intermediate relay control circuit 4 and an intermediate relay control circuit 5 .

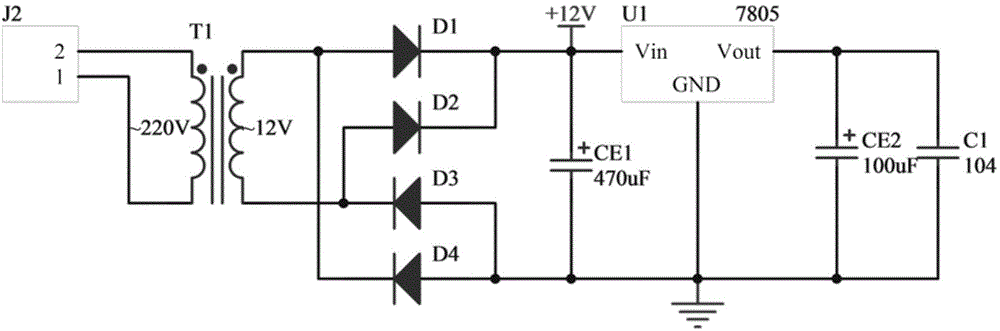

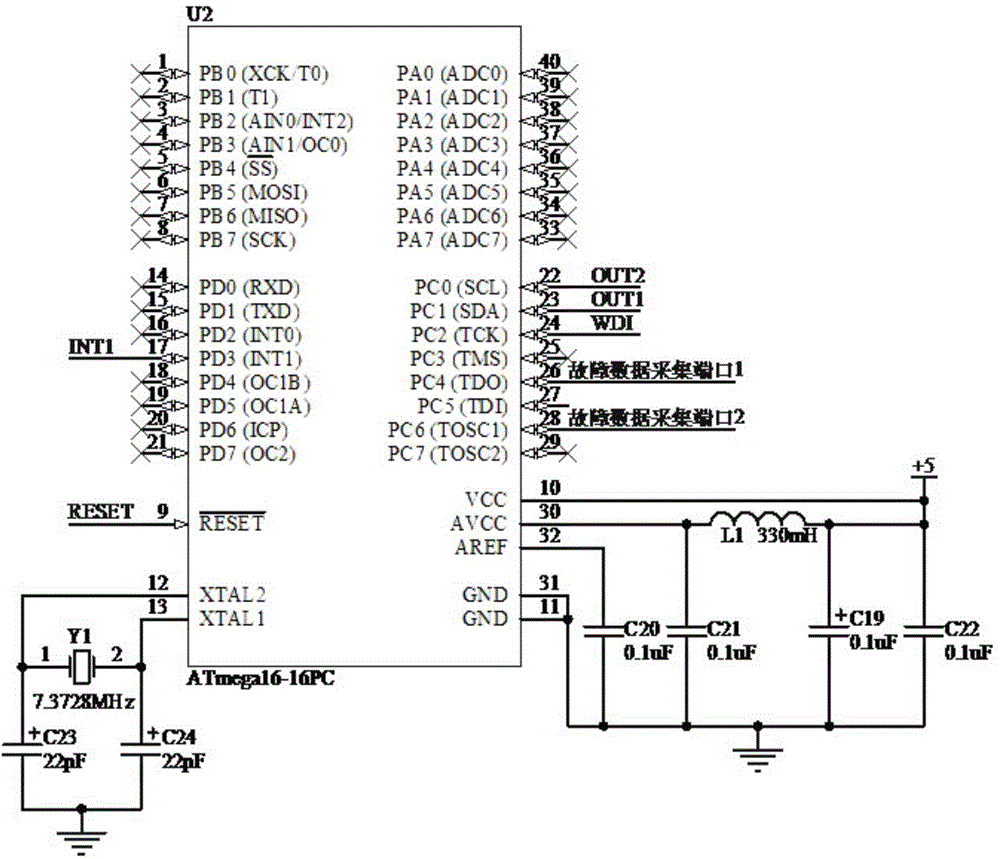

[0030] Among them, the regulated power supply 1 provides a stable voltage for the single-chip microcomputer 2, the status monitor 3 and the intermediate relay control circuits 4, 5. The state monitor 3 mainly ensures the safe and stable operation of the control program of the single-chip microcomputer 2 , monitors the operation status of the power supply 6 of the equipment, and feeds fault information to the single-chip microcomputer 2 . The single-chip microc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com