Sulfur-resistant methanation catalyst and preparation method thereof

A sulfur-resistant methanation and sulfur-resistant methane technology, which is applied in the field of sulfur-resistant methanation catalysts and their preparation, achieves the effects of less land occupation, good CH4 selectivity, and less heat dissipation in the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

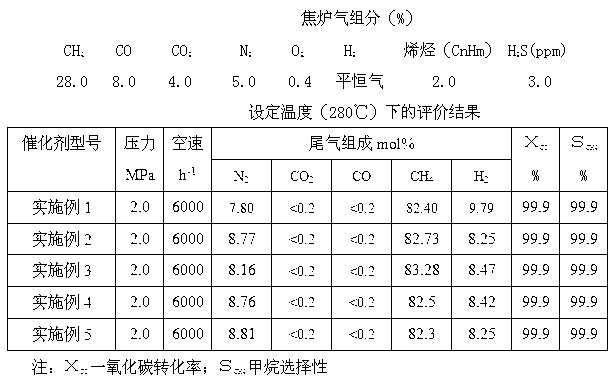

Examples

Embodiment 1

[0031] The sulfur-tolerant methanation catalyst of this embodiment uses Mo, Co and Ni oxides as active components, and Al 2 O 3 As the carrier, with La 2 O 3 As an accelerator, a precipitation catalyst with stearate as a lubricant. Among them, the weight ratio of each component is as follows:

[0032] compositionMo 2 O 3 CoO NiOLa 2 O 3 Al 2 O 3 Stearate Ratio22102905

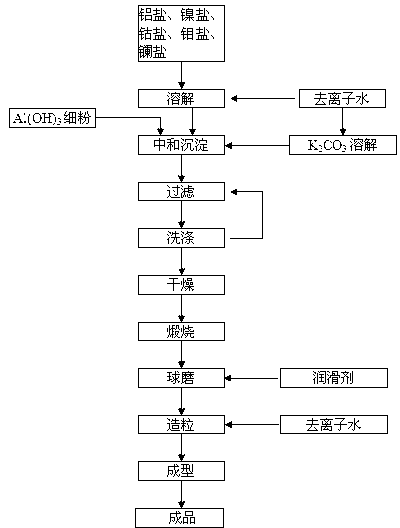

[0033] The preparation process of the sulfur-tolerant methanation catalyst of this embodiment is as follows figure 1 As shown, the preparation method of the sulfur-tolerant methanation catalyst of this embodiment mainly includes the following steps:

[0034] (1) Weigh the nitrate solids of the active components and accelerators in proportion and add deionized water to prepare a nitrate solution with a total mass content of each component of 15g / L. To the carrier Al 2 O 3 Add deionized water to the aluminum nitrate solid in the aluminum nitrate to prepare a nitrate solution with a mass content of 50g / L;

[003...

Embodiment 2

[0041] The sulfur-tolerant methanation catalyst of this embodiment uses Mo, Co and Ni oxides as active components, and Al 2 O 3 As the carrier, with La 2 O 3 It is a precipitation catalyst with graphite as lubricant as a promoter. Among them, the weight ratio of each component is as follows:

[0042] compositionMo 2 O 3 CoO3 NiOLa 2 O 3 Al 2 O 3 graphite Ratio55201852

[0043] The preparation process of the sulfur-tolerant methanation catalyst of this embodiment is as follows figure 1 As shown, the preparation method of the sulfur-tolerant methanation catalyst of this embodiment mainly includes the following steps:

[0044] (1) Weigh the nitrate solids of the active components and accelerators in proportion and add deionized water to prepare a nitrate solution with a total mass content of each component of 25g / L. To the carrier Al 2 O 3 Add deionized water to the aluminum nitrate solid in the aluminum nitrate to prepare a nitrate solution with a mass content of 45g / L;

[004...

Embodiment 3

[0051] The sulfur-tolerant methanation catalyst of this embodiment uses Mo, Co and Ni oxides as active components, and Al 2 O 3 As the carrier, with La 2 O 3 As an accelerator, a precipitation catalyst with paraffin as a lubricant. Among them, the weight ratio of each component is as follows:

[0052] compositionMo 2 O 3 CoO3 NiOLa 2 O 3 Al 2 O 3 paraffin Ratio44153953

[0053] The preparation process of the sulfur-tolerant methanation catalyst of this embodiment is as follows figure 1 As shown, the preparation method of the sulfur-tolerant methanation catalyst of this embodiment mainly includes the following steps:

[0054] (1) Weigh the nitrate solids of the active components and accelerators by adding deionized water to prepare a nitrate solution with a total mass content of each component of 20 g / L. To the carrier Al 2 O 3 Add deionized water to the aluminum nitrate solid in the aluminum nitrate to prepare a nitrate solution with a mass content of 55g / L;

[0055] (2) Add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com