Multistage duct type cobalt-based Fischer-Tropsch synthesis catalyst with core-shell structure and preparation method of multistage duct type cobalt-based Fischer-Tropsch synthesis catalyst

A core-shell structure and catalyst technology, which is applied in the field of core-shell structure multi-level channel cobalt-based Fischer-Tropsch synthesis catalyst and its preparation, can solve the problems of molecular sieve pore size distribution, low CO conversion rate, and conversion rate decline, and achieve Effects of preventing agglomeration, prolonging service life, and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

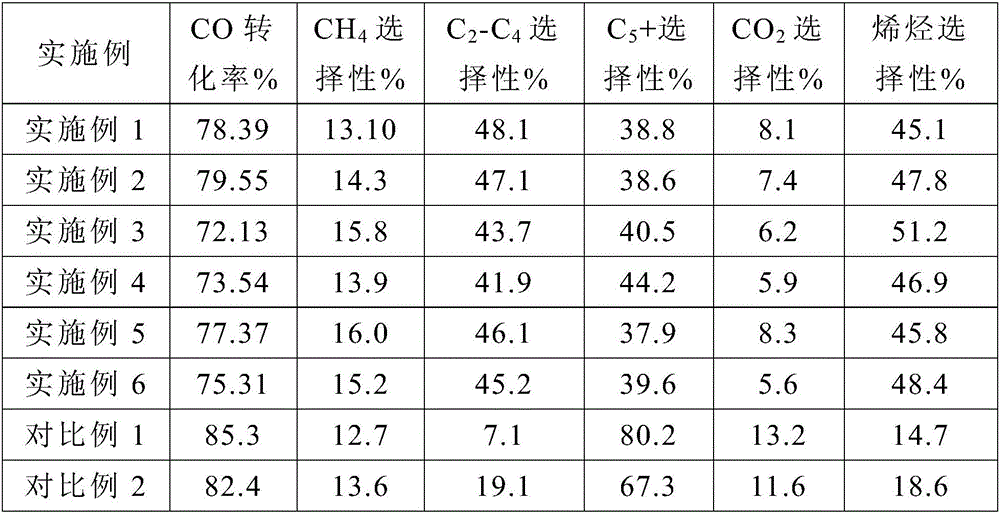

Examples

Embodiment 1

[0040] A core-shell structure multi-stage porous cobalt-based Fischer-Tropsch synthesis catalyst, comprising a catalyst carrier S, a metal active component Co loaded on the catalyst carrier S, and a shell molecular sieve membrane M wrapped on the surface of the catalyst carrier S, wherein, Catalyst support S is SiO 2 , SiO 2 The microstructure is spherical, and the average specific surface area is 210m 2 / g, the particle size range is 20-40 mesh; the shell molecular sieve membrane M is a cluster aggregate with uniform dispersion of H-ZSM-5 nanoparticles, and the average particle size range of H-ZSM-5 nanoparticles is 10-30nm. The pore diameter of its own micropores is less than or equal to 2.0nm, and the gap between adjacent H-ZSM-5 nanoparticles is less than or equal to 100nm; the loading amount of the metal active component Co accounts for 2% of the sum of the weight of the catalyst carrier S and the metal active component Co 15%.

[0041] Its preparation method comprises...

Embodiment 2

[0052] A core-shell structure multi-stage porous cobalt-based Fischer-Tropsch synthesis catalyst, comprising a catalyst carrier S, a metal active component Co loaded on the catalyst carrier S, and a shell molecular sieve membrane M wrapped on the surface of the catalyst carrier S, wherein, Catalyst support S is Al 2 o 3 , Al 2 o 3 The microstructure is spherical, and its average specific surface area is 290m 2 / g, the particle size range is 10-50 mesh; the shell molecular sieve membrane M is a cluster aggregate with evenly dispersed H-ZSM-5 nanoparticles, and the average particle size range of H-ZSM-5 nanoparticles is 10-30nm. The pore diameter of its own micropores is less than or equal to 2.0nm, and the gap between adjacent H-ZSM-5 nanoparticles is less than or equal to 100nm; the loading amount of the metal active component Co accounts for 2% of the sum of the weight of the catalyst carrier S and the metal active component Co 20%.

[0053] Its preparation method compri...

Embodiment 3

[0064] A core-shell structure multi-stage porous cobalt-based Fischer-Tropsch synthesis catalyst, comprising a catalyst carrier S, a metal active component Co loaded on the catalyst carrier S, and a shell molecular sieve membrane M wrapped on the surface of the catalyst carrier S, wherein, Catalyst support S is SiO 2 , SiO 2 The microstructure is spherical, and its average specific surface area is 170m 2 / g, the particle size range is 10-50 mesh; the shell layer molecular sieve membrane M is a cluster aggregate with evenly dispersed H-ZSM-5 nanoparticles, and the average particle size range of H-ZSM-5 nanoparticles is between 10-30nm , its own micropore diameter is less than or equal to 2.0nm, and the gap between adjacent H-ZSM-5 nanoparticles is less than or equal to 100nm; the loading amount of the metal active component Co accounts for the weight of the catalyst carrier S and the metal active component Co and 15%.

[0065] Its preparation method comprises the following s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com