Method for synthesizing flaky SAPO-34

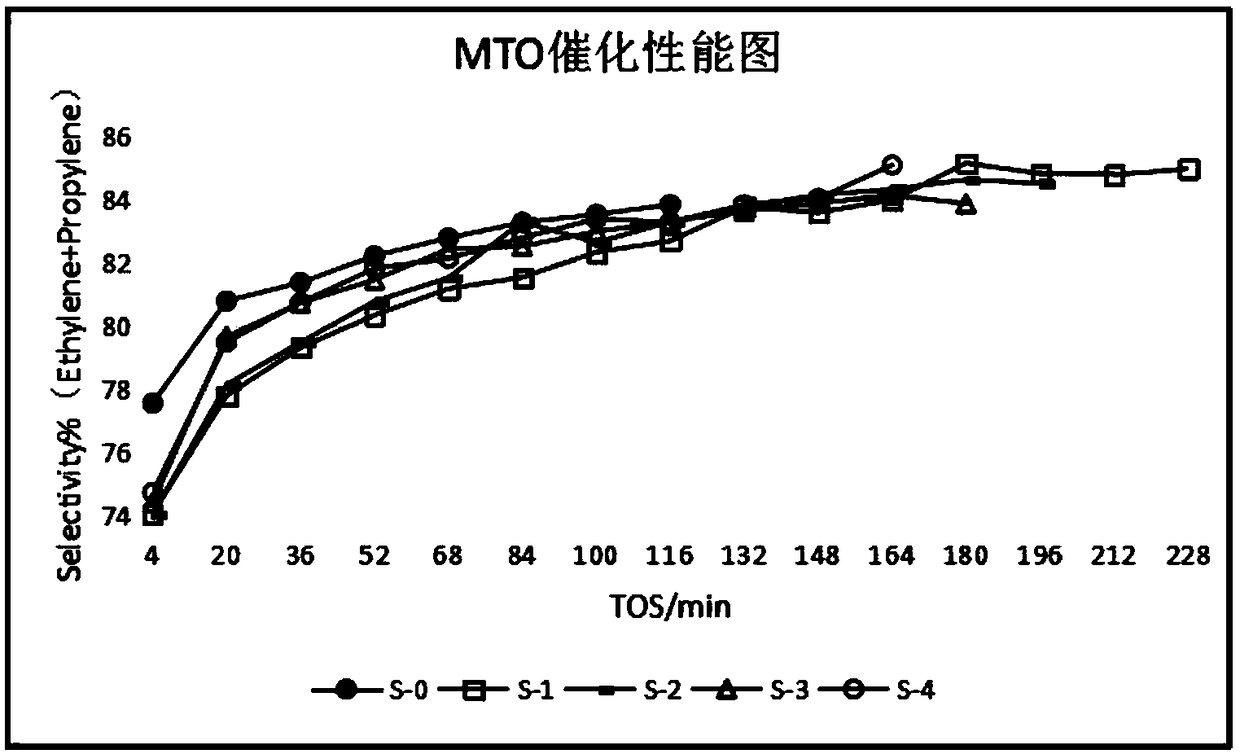

A technology for the synthesis of SAPO-34, which is applied in chemical instruments and methods, hydrocarbon production from oxygen-containing organic compounds, molecular sieves and alkali-exchanged phosphates, etc., can solve the problem of inability to achieve zero emissions, product performance is not guaranteed, and cannot achieve complete Recycling and other problems, to achieve the effect of strong anti-carbon deposition, excellent MTO catalytic performance, and extended single-pass catalytic life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

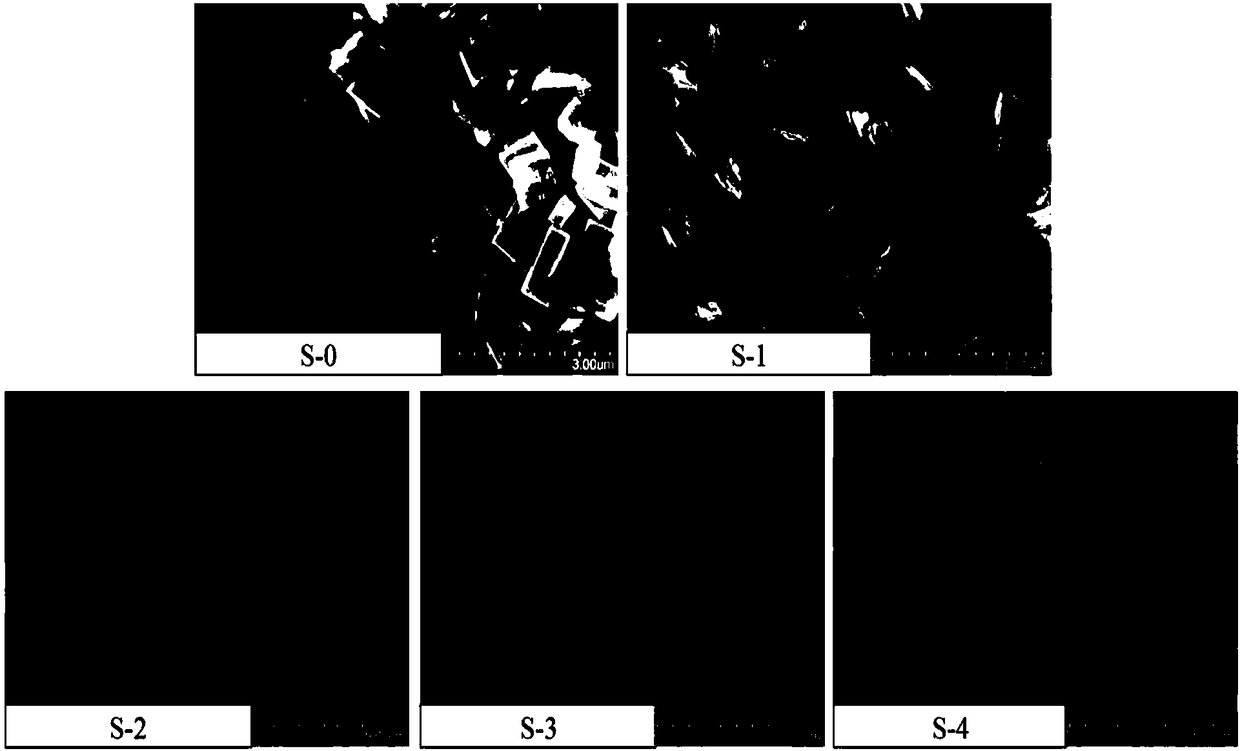

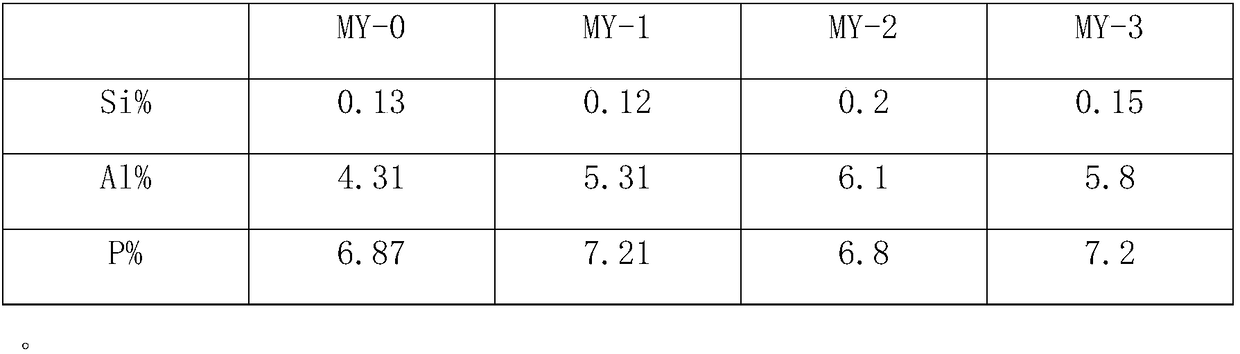

[0034] Take the MY-0 mother liquor and distill off part of the water under reduced pressure at 100°C to increase the solid content of the mother liquor to 70%. Add raw materials so that the molar ratio of each species is 1.0P (phosphoric acid): 1.0Al (pseudoboehmite): 0.2Si (silica sol): 0.05F (NH 4 F), uniformly dispersed, sealed and placed in a 100°C oven for pre-crystallization for 5 hours to obtain a crystal nucleus solution; then add aluminum source, silicon source, organic amine template agent and phosphorus source to deionized water in sequence, the molar ratio of each material is 1.0P 2 o 5 (phosphoric acid): 1.2Al 2 o 3 (pseudoboehmite): 0.06SiO 2 (silica sol): 1.0TEAOH: 50H 2 After the O is fully dispersed, the initial gel is made; the crystal nucleus solution is added to the initial gel to form a gel, and the amount of the crystal nucleus solution accounts for 30% of the total mass of the gel. After the gel is evenly dispersed, it is sealed and placed in an ove...

Embodiment 2

[0036] Take the MY-1 mother liquor and distill off part of the water under reduced pressure at 80°C to increase the solid content of the mother liquor to 70%. Add raw materials so that the molar ratio of each species is 1.0P (phosphoric acid): 1.0Al (pseudoboehmite): 0.4Si (silica sol): 0.75F (NH 4 F), uniformly dispersed, sealed and placed in an oven at 100°C for pre-crystallization for 10 hours to obtain a crystal nucleus solution; add aluminum source, silicon source, organic amine template agent and phosphorus source to deionized water in sequence, and the molar ratio of each material is 1.0 P 2 o 5 (phosphoric acid): 1.0Al 2 o 3 (pseudoboehmite): 0.3SiO 2 (silica sol): 2.0TEA: 40H 2 O; Add the crystal nucleus solution to the initial gel to make a gel. The amount of the crystal nucleus solution accounts for 40% of the total mass of the gel. After the gel is evenly dispersed, it is sealed and placed in a 170°C oven for crystallization for 48 hours. After the reaction, c...

Embodiment 3

[0038]Take the MY-2 mother liquor and distill off part of the water under reduced pressure at 60°C to increase the solid content of the mother liquor to 60%. Add raw materials so that the molar ratio of each species is 1.0P (phosphoric acid): 1.0Al (pseudoboehmite): 0.6Si (silica sol): 0.2F (HF), after the dispersion is uniform, seal and place in a 140°C oven for pre-crystallization After melting for 5 hours, the crystal nucleus solution was obtained; the aluminum source, the silicon source, the organic amine template agent and the phosphorus source were added to the deionized water successively, and the molar ratio of each material was 1.0P 2 o 5 (phosphoric acid): 0.8Al 2 o 3 (pseudoboehmite): 0.6SiO 2 (Orthoethyl silicate): 2.DEA: 30H 2 O: Add the crystal nucleus solution to the initial gel to make a gel. The amount of crystal nucleus solution added is 50% of the total mass of the gel. After the gel is evenly dispersed, it is sealed and placed in a 200°C oven for crysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com