Sulfur-resistant methanation catalyst and preparation method thereof

A technology for sulfur-resistant methanation and catalyst, which is applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., to achieve small footprint, good CH4 selectivity, and wide application market effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

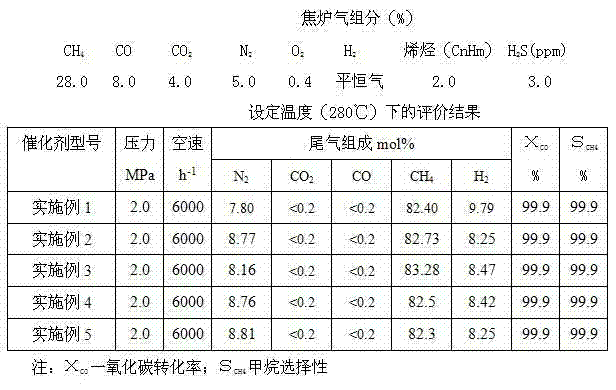

Examples

Embodiment 1

[0031] The sulfur-tolerant methanation catalyst of this embodiment is based on the oxides of Mo, Co and Ni as active components, and Al 2 o 3 as the carrier, with La 2 o 3 It is a precipitated catalyst with stearate as a lubricant. Wherein, the proportioning by weight of each component is as follows:

[0032] composition Mo 2 o 3 CoO NiO La 2 o 3 al 2 o 3 Stearate Proportion 2 2 10 2 90 5

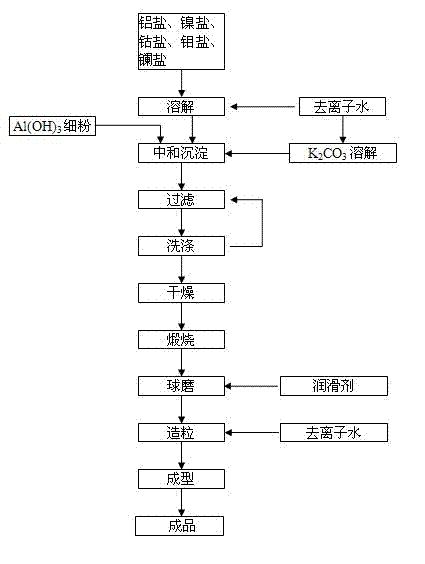

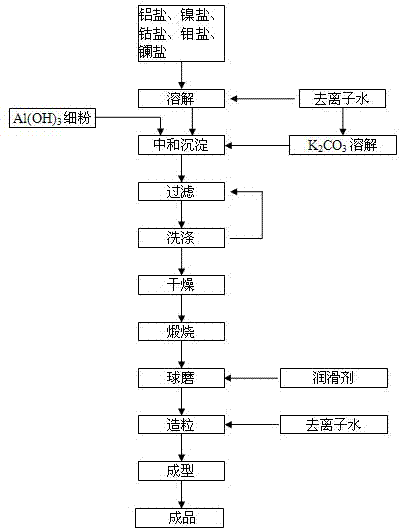

[0033] The preparation process of the sulfur-resistant methanation catalyst of this embodiment is as follows figure 1As shown, the preparation method of the sulfur-resistant methanation catalyst in this embodiment mainly includes the following steps:

[0034] (1) Add deionized water to the nitrate solids of active components and accelerators in proportion to prepare a nitrate solution with a total mass content of each component of 15g / L. To the carrier Al 2 o 3 The aluminum nitrate solid in is added deionized water, is mixed with the ni...

Embodiment 2

[0041] The sulfur-tolerant methanation catalyst of this embodiment is based on the oxides of Mo, Co and Ni as active components, and Al 2 o 3 as the carrier, with La 2 o 3 As a promoter, a precipitated catalyst with graphite as a lubricant. Wherein, the proportioning by weight of each component is as follows:

[0042] composition Mo 2 o 3 CoO3 NiO La 2 o 3 Al 2 o 3 graphite Proportion 5 5 20 1 85 2

[0043] The preparation process of the sulfur-resistant methanation catalyst of this embodiment is as follows figure 1 As shown, the preparation method of the sulfur-resistant methanation catalyst in this embodiment mainly includes the following steps:

[0044] (1) Add deionized water to the nitrate solids of active components and accelerators in proportion to prepare a nitrate solution with a total mass content of each component of 25g / L. To the carrier Al 2 o 3 The aluminum nitrate solid in is added deionized water, is mixed ...

Embodiment 3

[0051] The sulfur-tolerant methanation catalyst of this embodiment is based on the oxides of Mo, Co and Ni as active components, and Al 2 o 3 as the carrier, with La 2 o 3 It is a precipitated catalyst with paraffin wax as a lubricant. Wherein, the proportioning by weight of each component is as follows:

[0052] composition Mo 2 o 3 CoO3 NiO La 2 o 3 al 2 o 3 paraffin Proportion 4 4 15 3 95 3

[0053] The preparation process of the sulfur-resistant methanation catalyst of this embodiment is as follows figure 1 As shown, the preparation method of the sulfur-resistant methanation catalyst in this embodiment mainly includes the following steps:

[0054] (1) Add deionized water to the nitrate solids of active components and accelerators in proportion to prepare a nitrate solution with a total mass content of each component of 20g / L. To the carrier Al 2 o 3 The aluminum nitrate solid in is added deionized water, is mixed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com