Coke oven gas hydrodesulfurization catalyst and preparation method thereof

A technology for hydrodesulfurization and coke oven gas, which is applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Disproportionation carbon deposition and other problems, to achieve the effect of improving anti-carbon deposition ability, strong anti-carbon deposition ability, and improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

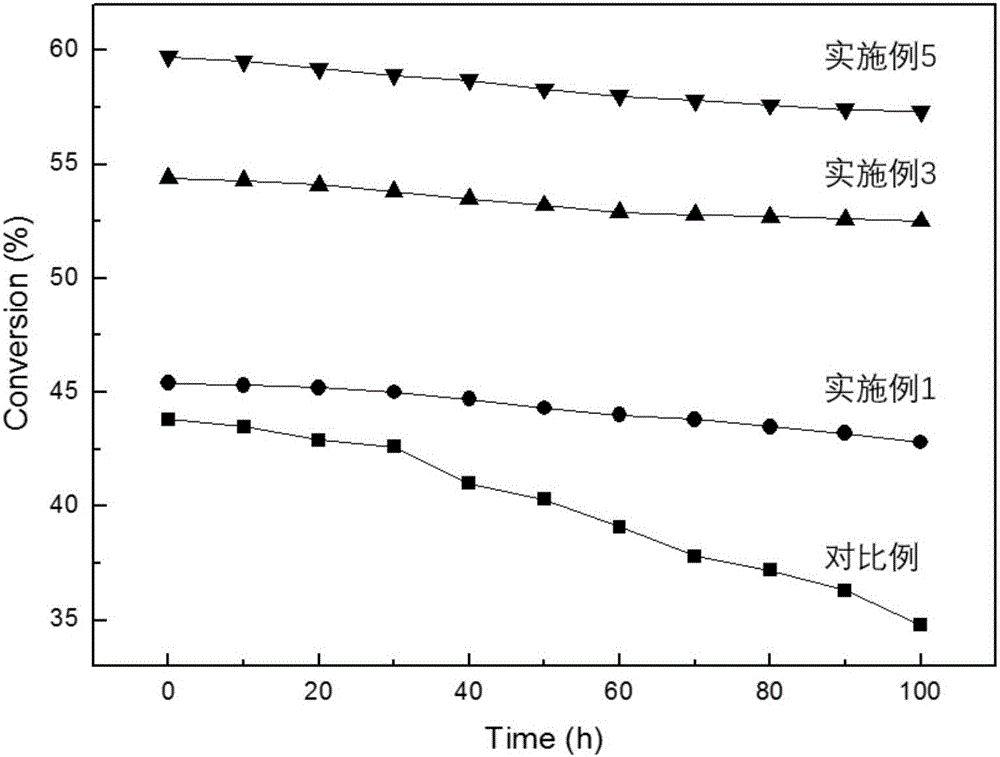

Embodiment 1

[0031] Weigh 26.9g Fe(NO 3 ) 3 9H 2 O, 1.0 g KNO 3 Dissolve in 82.5g of water, add 28.8g of oxalic acid, add 18.0g of ammonium heptamolybdate under stirring conditions, put it in a constant temperature water bath at 70°C after dissolving, add 150g of alumina carrier, soak for 2h, and then place the product at 120°C Bake at the bottom for 10 hours, and then bake at 350°C for 2 hours to obtain the finished catalyst. The content of each component is: Fe 2 o 3 3.1%, MoO 3 8.6%, Al 2 o 3 88.2%, K 2 O 0.1%.

Embodiment 2

[0033] Weigh 8.7g Fe(NO 3 ) 3 9H 2 O, 5.0g NaNO 3 Dissolve in 82.5g of water, add 13.8g of oxalic acid, add 22.0g of ammonium heptamolybdate under stirring conditions, dissolve it in a constant temperature water bath at 30°C, add 150g of alumina carrier, soak for 2h, and then place the product at 120°C Baked for 10 hours, then calcined for 1 hour at 450°C to obtain the finished catalyst. The content of each component is: Fe 2 o 3 1.0%, MoO 3 10.4%, Al 2 o 3 87.5%, Na 2 O 1.1%.

Embodiment 3

[0035] Dissolve 10.0g of tetramethoxysilane in a mixed solution of 40mL of water and 50mL of ethanol, add 150g of alumina carrier and impregnate at 30°C for 30min, then bake at 150°C for 1h, and roast at 400°C for 1h to obtain SiO 2 Modified alumina carrier 153.9g.

[0036] Weigh 28.0g Fe(NO 3 ) 3 9H 2 O, 4.0 g KNO 3 Dissolve in 82.5g of water, add 30.0g of oxalic acid, add 18.0g of ammonium heptamolybdate under stirring conditions, put it into a constant temperature water bath at 50°C after dissolving, add the aforementioned SiO 2 153.9 g of the modified alumina carrier was impregnated for 4 hours, and then the product was baked at 150°C for 1 hour and calcined at 450°C for 1 hour to obtain the finished catalyst. The content of each component is: Fe 2 o 3 3.2%, MoO 3 8.3%, Al 2 o 3 85.2%, K 2 O 1.1%, SiO 2 2.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com