Nickel-cobalt based catalyst as well as preparation method and application thereof

A catalyst, a nickel-cobalt-based technology, applied in the field of nickel-cobalt-based catalysts and their preparation, can solve problems such as gas blockage and disasters, and achieve the effects of cost reduction, strong carbon deposition resistance, and good reaction stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 3.62g of cerium nitrate and dissolve in water to form cerium nitrate aqueous solution; dry 10.00g of γ-Al at room temperature 2 o 3 Immerse in the prepared cerium nitrate aqueous solution for 12 hours by equal volume impregnation method; dry at 120°C for 24 hours; bake at 450°C for 2 hours in air atmosphere to obtain the modified carrier.

[0028] Weigh 1.19g nickel nitrate and 1.77g cobalt nitrate and dissolve in water to make a mixed aqueous solution of nickel nitrate and cobalt nitrate; 12 hours in the mixed aqueous solution; drying at 120° C. for 24 hours; calcining at 700° C. for 5 hours in an air atmosphere to obtain a catalyst precursor.

[0029] The prepared catalyst precursor was reduced in hydrogen at 900 °C for 2 hours.

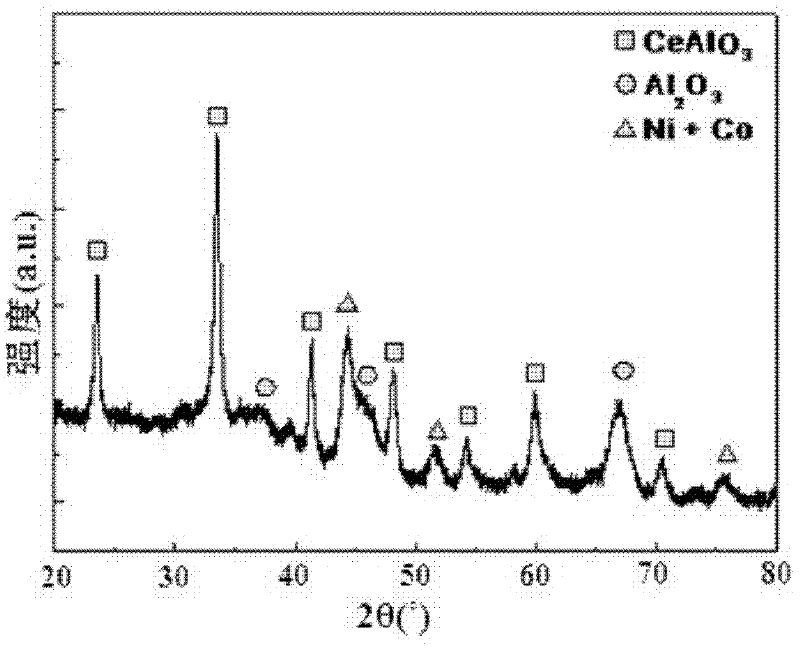

[0030] figure 1 For the XRD collection of collections of catalysts that the present embodiment makes, by figure 1 It can be seen that the prepared catalyst is composed of four phases of metal nickel, metal cobalt, cerium aluminate ...

Embodiment 2

[0037] Weigh 3.46g of cerium nitrate and dissolve in water to form cerium nitrate aqueous solution; dry 10.00g of γ-Al at room temperature 2 o 3 Immerse in the prepared cerium nitrate aqueous solution for 12 hours by equal volume impregnation method; dry at 120°C for 24 hours; bake at 450°C for 2 hours in air atmosphere to obtain the modified carrier.

[0038] Weigh 0.28g nickel nitrate and 0.28g cobalt nitrate and dissolve in water to make a mixed aqueous solution of nickel nitrate and cobalt nitrate; 12 hours in the mixed aqueous solution; drying at 120° C. for 24 hours; calcining at 700° C. for 5 hours in an air atmosphere to obtain a catalyst precursor.

[0039] The prepared catalyst precursor was reduced in hydrogen at 900 °C for 2 hours.

[0040] The XRD spectrum of the catalyst prepared in this example shows that the prepared catalyst is composed of four phases of metallic nickel, metallic cobalt, cerium aluminate and aluminum oxide.

[0041] After X-ray diffraction ...

Embodiment 3

[0047] Weigh 4.42g of cerium nitrate and dissolve in water to form cerium nitrate aqueous solution; dry 10.00g of γ-Al at room temperature 2 o 3 Immerse in the prepared cerium nitrate aqueous solution for 12 hours by equal volume impregnation method; dry at 120°C for 24 hours; bake at 450°C for 2 hours in air atmosphere to obtain the modified carrier.

[0048] Take by weighing 10.84g nickel nitrate and 3.60g cobalt nitrate and dissolve in water and be made into the mixed aqueous solution of nickel nitrate and cobalt nitrate; 12 hours in the mixed aqueous solution; drying at 120° C. for 24 hours; calcining at 700° C. for 5 hours in an air atmosphere to obtain a catalyst precursor.

[0049] The prepared catalyst precursor was reduced in hydrogen at 900 °C for 2 hours.

[0050] The XRD spectrum of the catalyst prepared in this example shows that the prepared catalyst is composed of four phases of metallic nickel, metallic cobalt, cerium aluminate and aluminum oxide.

[0051] A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com