Method for producing hydrogen through coupled catalytic reforming and membrane separation reaction, and device thereof

A technology of catalytic reforming and membrane separation, applied in chemical instruments and methods, hydrogen separation, hydrogen, etc., can solve the problems of large heat transfer and diffusion resistance, large axial temperature gradient, shortened reaction process, etc., to achieve enhanced gas-solid Effect of mass transfer and heat transfer, high conversion rate, and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

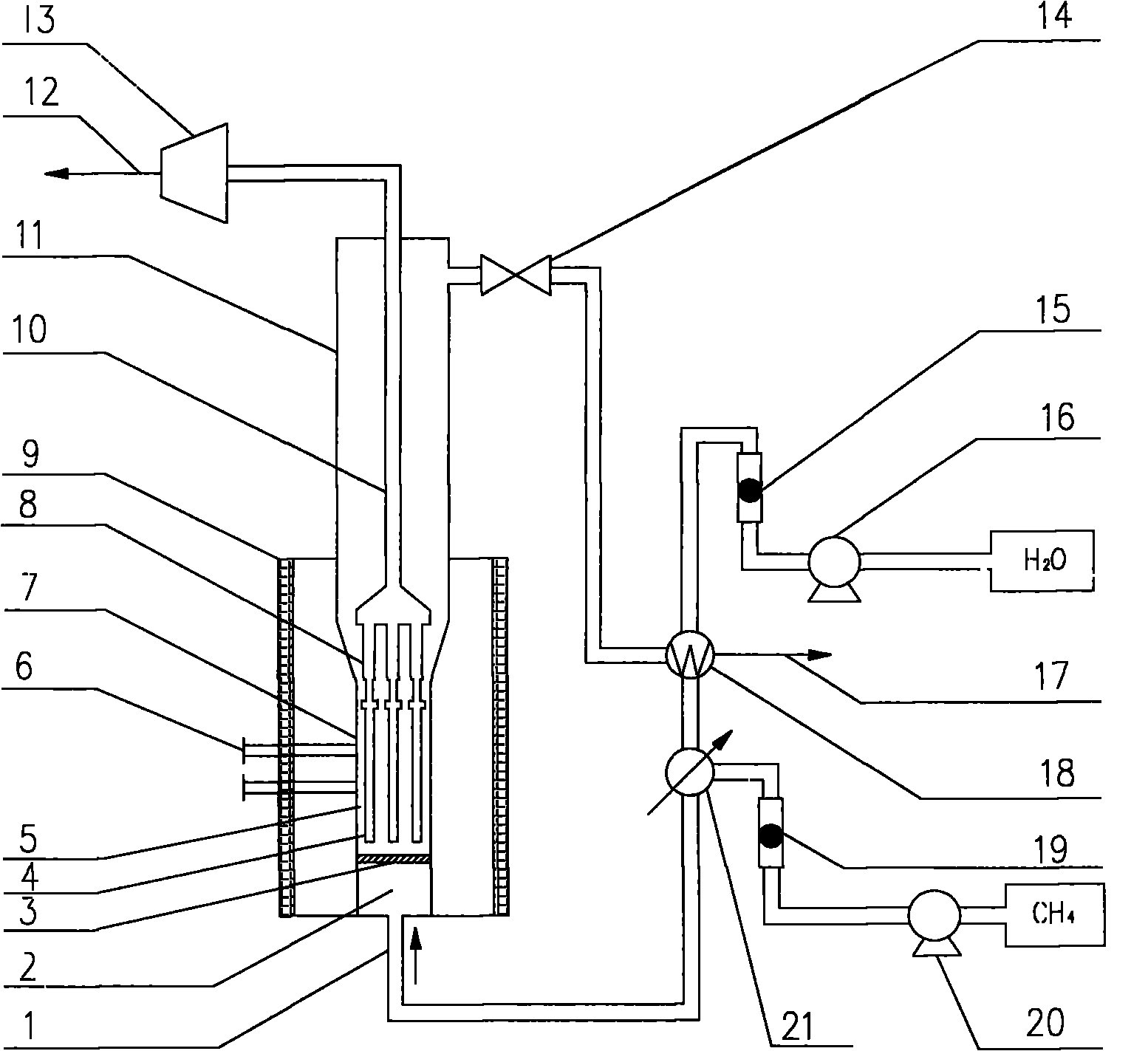

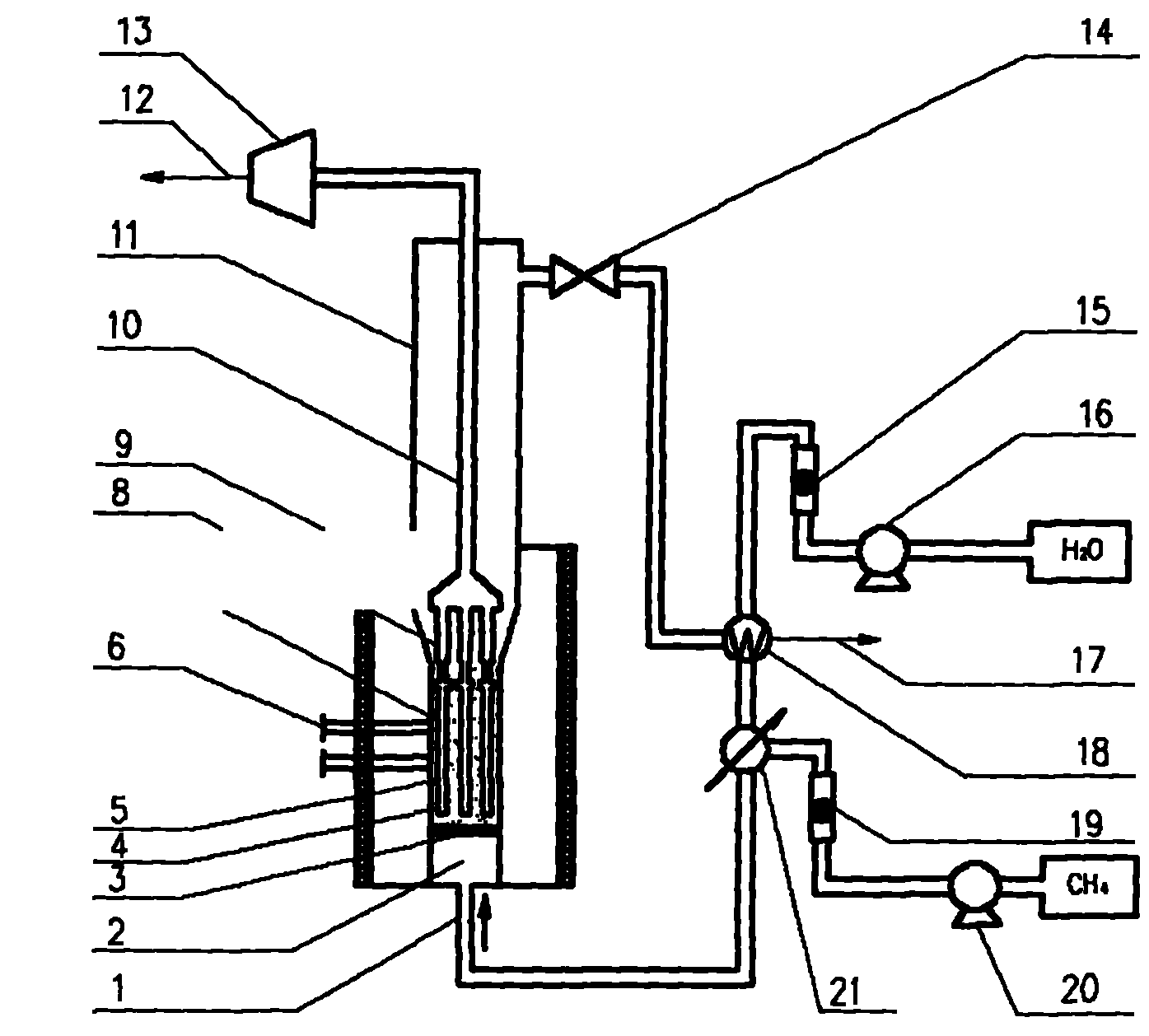

[0016] The main structure of this embodiment includes a raw material gas inlet 1, a pre-distribution chamber 2, a gas distribution plate 3, a palladium membrane module 4, a catalyst bed 5, a sampling port 6, a reaction zone bed 7, a metal connecting pipe 8, and a heating system 9 , hydrogen conduit 10, expansion section 11, ultra-pure hydrogen outlet 12, vacuum pump 13, back pressure valve 14, liquid rotameter 15, water pump 16, tail gas outlet 17, heat exchanger 18, gas rotameter 19, gas pump 20 And the preheater 21, the components are combined to form a hydrogen selective membrane fluidized bed methane steam reforming hydrogen production device or reactor; the bottom of the device is equipped with a raw material gas inlet 1, and a pre-distribution chamber is arranged on the upper part of the raw material gas inlet 1 2. A gas distribution plate 3 is formed between the pre-distribution chamber 2 and the bed body 7 in the fluidized bed reaction zone, and the pre-distribution cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com