Simple and convenient preparation method for nickle/graphene-like carbon nitride compound composite catalyst

A technology of olefinic carbon nitrogen compounds and composite catalysts, applied in the field of photocatalytic hydrogen production and material science, can solve environmental pollution, crisis and other problems, achieve the effect of reducing cost, reducing use cost and improving catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

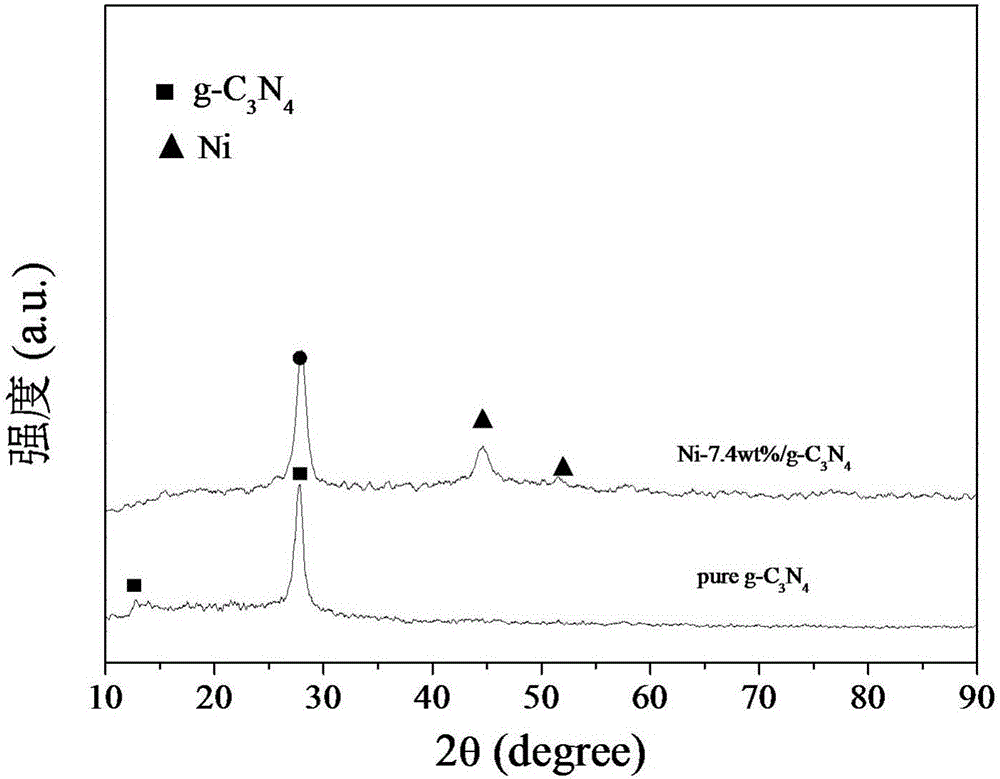

[0017] (1) Take 20g of thiourea and place it in 4 crucibles, place the crucibles in a muffle furnace and raise the temperature to 550°C at a rate of 2 degrees per minute, calcinate for two hours, take out the crucibles when the temperature drops to room temperature, and grind the solid into Powder, put the crucible containing the solid powder in a muffle furnace, raise the temperature to 500°C at a rate of 2°C per minute, calcinate for two hours, and take out the yellow-white solid powder after cooling down to room temperature to obtain graphene-like carbon nitrogen compounds;

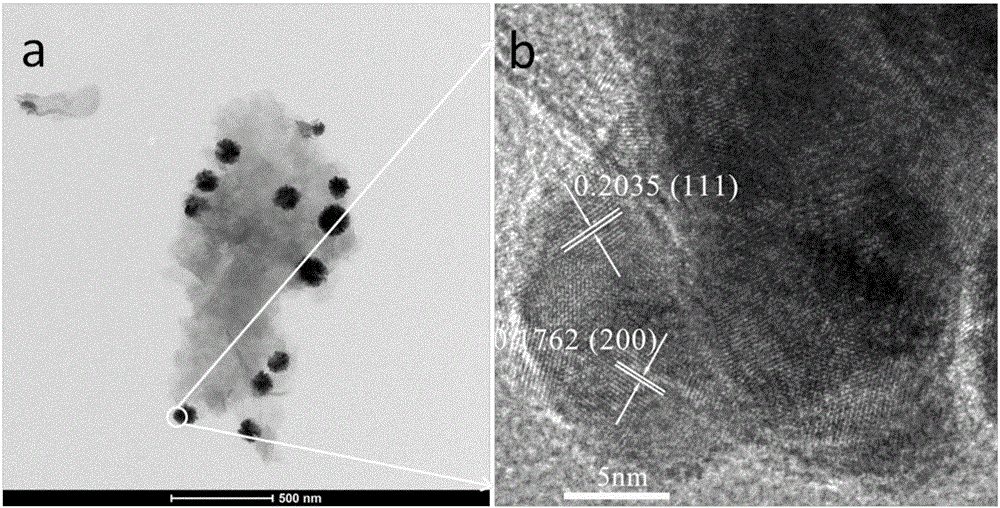

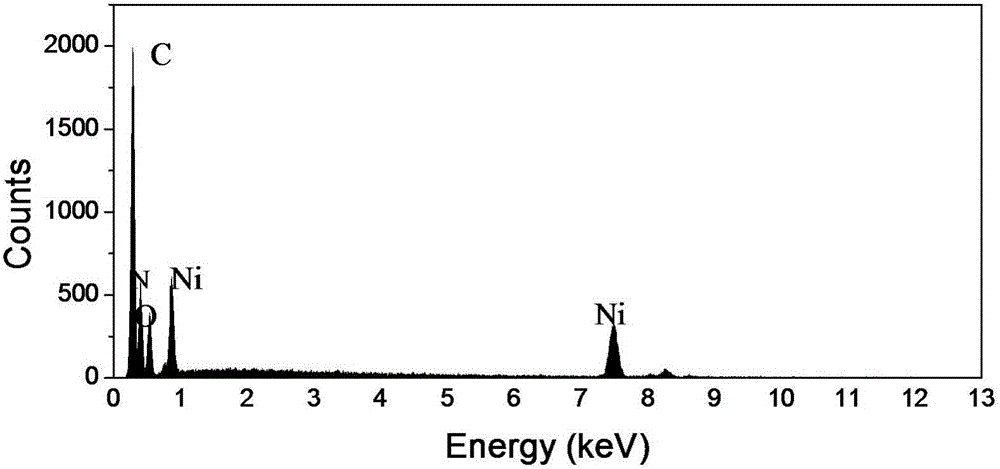

[0018] (2) Get 10mg of graphene carbon nitrogen compound and place it in a 25mL single-necked flask, then add 3mL of triethanolamine, 0.3mL of nickel sulfide aqueous solution (0.1mol / L), 2.1mL of sodium hypophosphite (molecular formula NaH 2 PO 2 ) aqueous solution (0.1mol / L), 4.6mL water, ultrasonic dispersion treatment for 30s, and then use nitrogen degassing for 40min to remove oxygen in the reactio...

Embodiment 2

[0022] (1) 10 mg of graphene-like carbonitrides in Example 1 is placed in a 25 mL round-bottomed flask, then 3 mL of triethanolamine is added, 0.2 mL of nickel sulfide aqueous solution (0.1mol / L), 1.4 mL of sodium hypophosphite (molecular formula NaH 2 PO 2 ) aqueous solution (0.1mol / L), 5.4mL water, ultrasonic dispersion treatment for 30s, and then use nitrogen degassing for 40min to remove oxygen in the reaction system;

[0023] (2) After the degassing is completed, place the round-bottomed flask under a 300W xenon lamp for 30 minutes, then centrifuge the obtained solid, wash it with deionized water 5 times, wash it with ethanol twice, and dry the solid at 80°C for 10 hours under vacuum. The obtained black substance is nickel simple substance / graphene-like carbon-nitrogen compound composite catalyst. The mass percent content of nickel in the prepared nickel simple substance / graphene-like carbonitride compound catalyst is 3.8%.

Embodiment 3

[0025] (1) 10 mg of graphene-like carbonitrides in Example 1 is placed in a 25 mL round-bottomed flask, then 3 mL of triethanolamine is added, 0.4 mL of nickel sulfide aqueous solution (0.1mol / L), 2.8 mL of sodium hypophosphite (molecular formula NaH 2 PO 2 ) aqueous solution (0.1mol / L), 3.8mL water, ultrasonic dispersion treatment for 30s, and then use nitrogen degassing for 40min to remove oxygen in the reaction system;

[0026] (2) After the degassing is completed, place the round-bottomed flask under a 300W xenon lamp for 30 minutes, then centrifuge the obtained solid, wash it with deionized water 5 times, wash it with ethanol twice, and dry the solid at 80°C for 10 hours under vacuum. The obtained black substance is nickel simple substance / graphene-like carbon-nitrogen compound composite catalyst. The mass percent content of nickel in the prepared nickel simple substance / graphene-like carbonitride compound catalyst is 12.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com