Composite visible light photocatalyst loaded with two promoters at the same time and application thereof

A technology of co-catalyst and photocatalyst, which is applied in the field of catalyst preparation and the sustainable development of environment and energy, can solve the problems of limited large-scale application and high precious metals, and achieves low production cost, good stability, and is conducive to sustainable development. effect of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

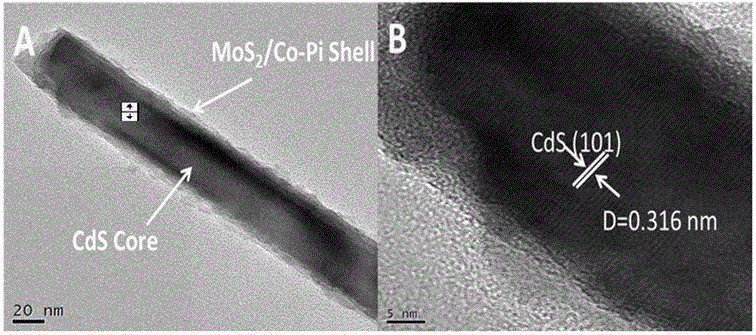

[0025] A composite visible light photocatalyst supporting dual co-catalysts at the same time, and its preparation method comprises the following steps:

[0026] 1) Prepare a mixed solution of water and ethanol at a volume ratio of 4:1, ultrasonically disperse the CdS nanowires in the resulting mixed solution, and bubbling with nitrogen for 0.5 hours;

[0027] 2) Under the protection of nitrogen, add the ammonium tetrathiomolybdate solution to the dispersion obtained in step 1), and then irradiate it under visible light for 0.5 hours, filter, wash, and dry to obtain CdS / MoS 2 Composite material, MoS 2 The loading capacity is 2% of the weight of CdS;

[0028] 3) The CdS / MoS obtained in step 2) 2 The composite material was ultrasonically dispersed in a phosphate buffer (concentration 0.01M) with a pH of 7.0, and then cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O), irradiate with visible light for 10 minutes, filter, wash, and dry to obtain CdS / MoS 2 / Co-Pi composite visible light photocatalyst, in...

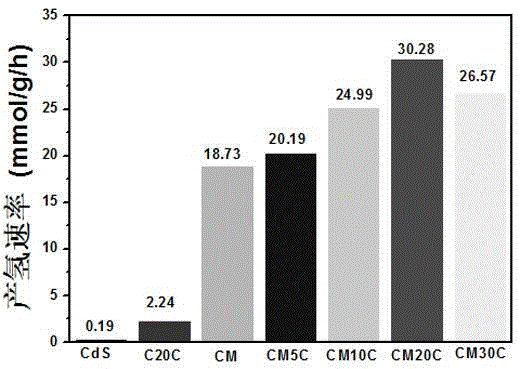

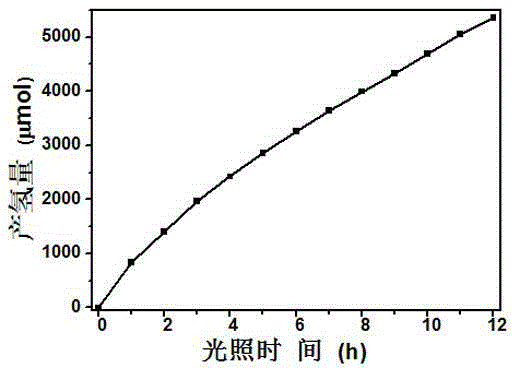

Embodiment 1

[0031] Add 50mgCdSNWs, 24mLH 2 O, 8mLC 2 H 5 OH was mixed and stirred uniformly, after 0.5 hours of nitrogen, 1mL, 1.61mg / mL (NH 4 ) 2 MoS 4 The aqueous solution is irradiated with visible light with a wavelength greater than 420nm for 0.5 hours while keeping nitrogen flowing, then the solution is centrifuged, washed three times with ethanol, and then dried under nitrogen at room temperature to obtain CdS / MoS 2 Composite materials, where MoS 2 The load is 2%; take 50mg of CdS / MoS 2 The composite material was dispersed in 25mL, pH=7 phosphate buffer solution (concentration 0.01M), and 0.5mL, 18.26mM Co(NO 3 ) 2 ·6H 2 O solution, placed in visible light (wavelength> 420nm) light for 10min, then centrifuge the solution, wash three times with ethanol, then place it in room temperature and dry it with nitrogen to obtain a load of 2% MoS 2 , 5%Co-Pi one-dimensional core-shell structure CdS / MoS 2 / Co-Pi composite visible light photocatalyst, denoted as CM5C.

Embodiment 2

[0033] Add 50mgCdSNWs, 24mLH 2 O, 8mLC 2 H 5 OH was mixed and stirred uniformly, after 0.5 hours of nitrogen, 1mL, 1.61mg / mL (NH 4 ) 2 MoS 4 The aqueous solution is irradiated with visible light with a wavelength greater than 420nm for 0.5 hours while keeping nitrogen flowing, then the solution is centrifuged, washed three times with ethanol, and then dried under nitrogen at room temperature to obtain CdS / MoS 2 Composite materials, where MoS 2 The loading capacity is 2%; take 50mg CdS / MoS 2 The composite material was dispersed in 25mL, pH=7 phosphate buffer solution (concentration 0.01M), and 1mL, 18.26mM Co(NO 3 ) 2 ·6H 2 O solution, placed in visible light (wavelength> 420nm) light for 10min, then centrifuge the solution, wash three times with ethanol, then place it in room temperature and dry it with nitrogen to obtain a load of 2% MoS 2 , 10% Co-Pi one-dimensional core-shell structure CdS / MoS 2 / Co-Pi composite visible light photocatalyst, denoted as CM10C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com