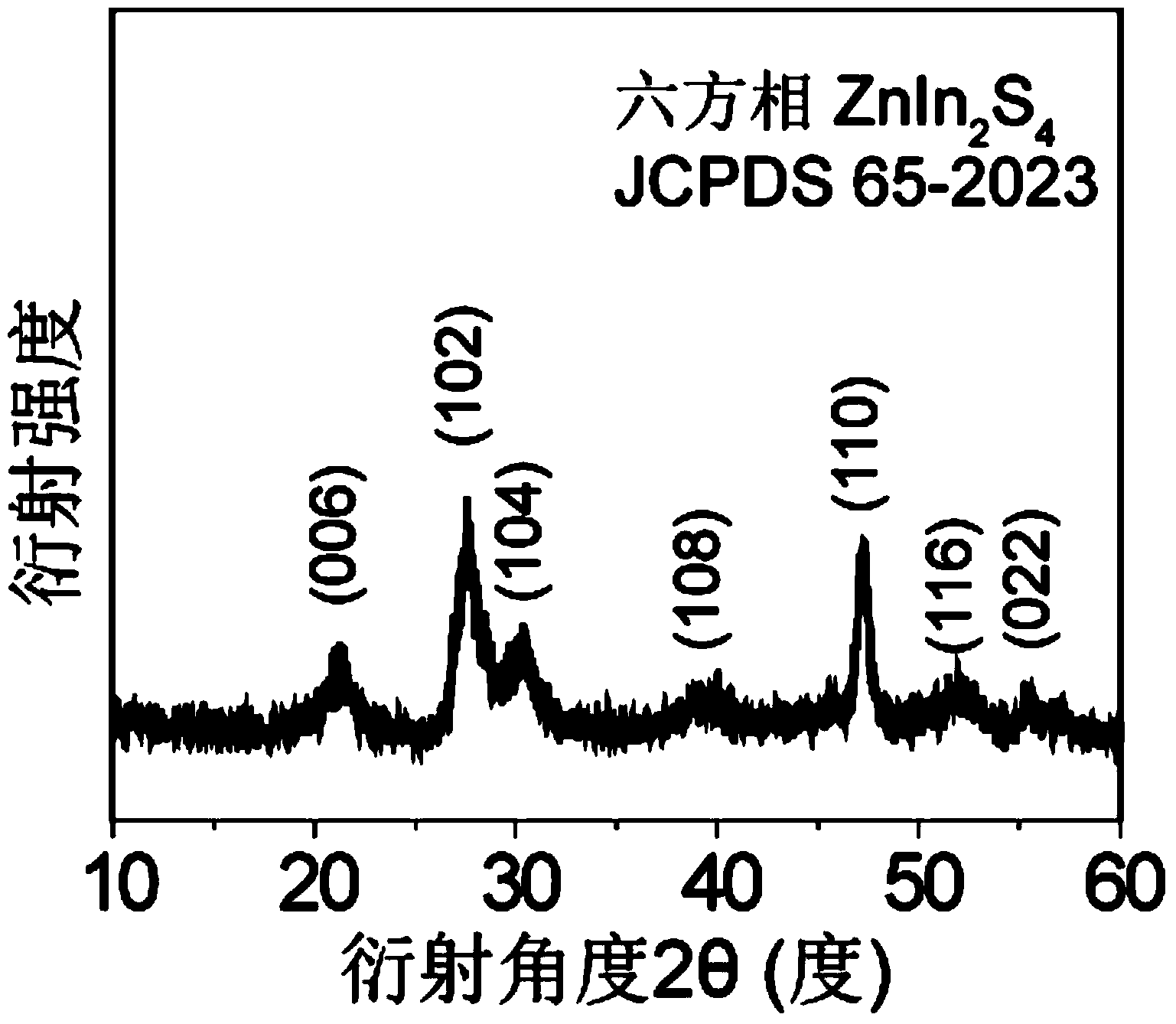

Carbon quantum dot, precious metal and zinc indium sulfide composite photocatalyst and preparation method thereof

A technology of indium zinc sulfide and carbon quantum dots, which is applied in the field of photocatalysis, can solve the problems of unsuitability for industrial production, high catalyst preparation cost, and large size of precious metal particles, and achieves excellent ability to capture electrons, excellent storage and transmission of electrons. Good performance and adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

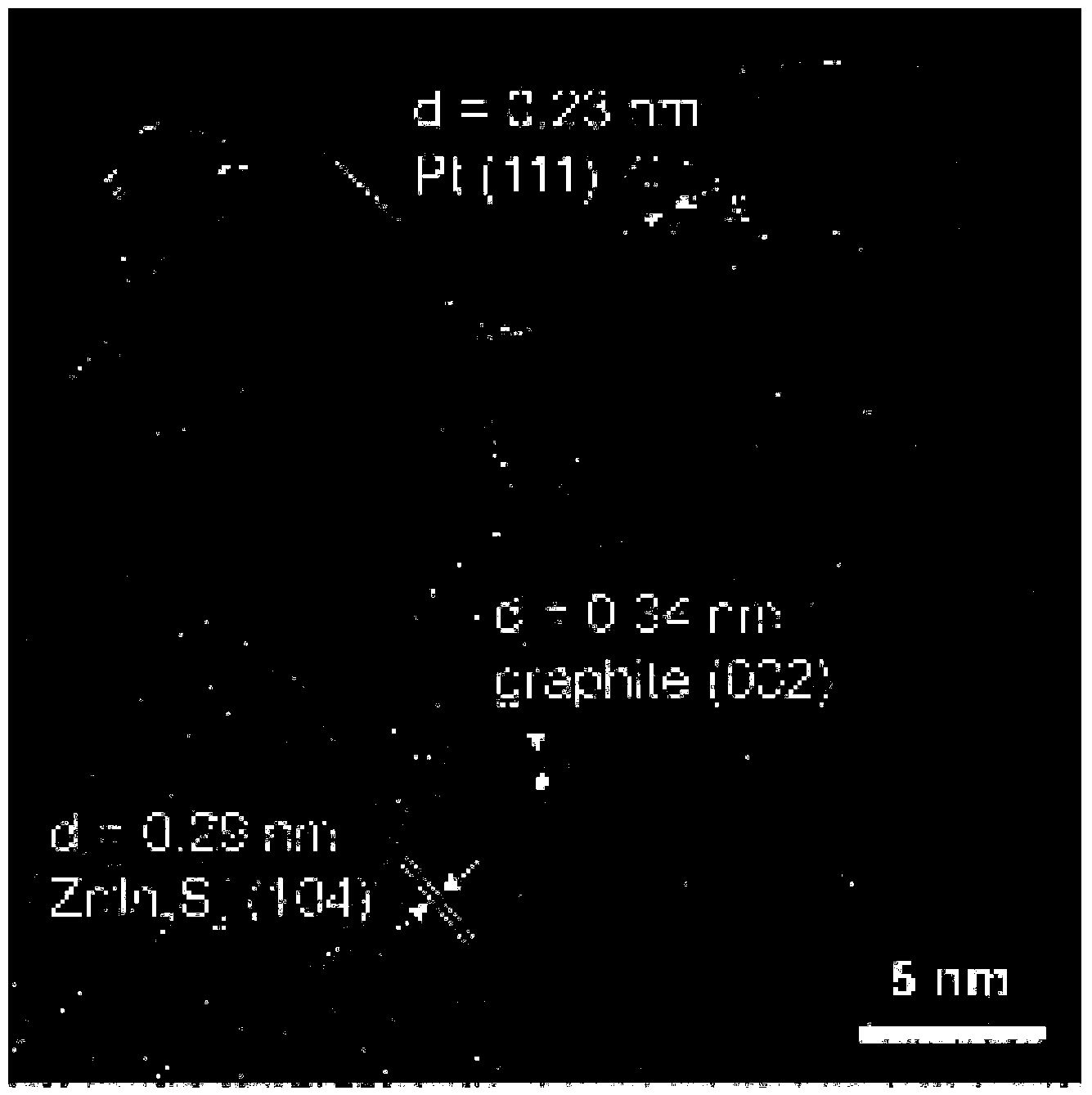

Embodiment 1

[0028] Disperse 1mmol of zinc chloride, 2mmol of indium chloride and 4mmol of thiourea in a mixed solution of 2mL of ethanol, 2mL of acetone and 20mL of water, add 1mL of 1-butyl-3-methylimidazolium tetrafluoroborate, and then add 5mL of It was an ethanol dispersion of carbon quantum dots at 1 mg / mL, and stirred for 30 minutes to obtain a uniform and transparent mixed solution. The mixed solution was transferred to a reaction kettle, and then placed in a microwave hydrothermal synthesizer for microwave hydrothermal treatment at 200° C. for 1 hour. The power of the microwave hydrothermal synthesizer was 800W. After the reactor was cooled to room temperature, the precipitate was collected by centrifugation, washed with water and ethanol several times in sequence, and then dried at 80°C to obtain the reduced carbon quantum dot and indium zinc sulfide complex. Disperse 0.1g of the above compound in 10mL water, add 20mg polyethylene glycol 2000 and 0.05mL chloroplatinic acid hexahydr...

Embodiment 2

[0031] Disperse 1mmol of zinc acetate, 2mmol of indium acetate and 20mmol of thioacetamide in a mixed solution of 5mL of ethanol, 25mL of acetone and 50mL of water, add 8mL of 1-butyl-3-methylimidazole chloride, and then add 2.5mL of 10 mg / mL ethanol solution of carbon quantum dots was stirred for 30 min to obtain a uniform and transparent mixed solution. The mixed solution was transferred to a reaction kettle, and placed in a microwave hydrothermal synthesizer for microwave hydrothermal treatment at 240° C. for 0.5 h. The power of the microwave hydrothermal synthesizer was 300W. After the reaction kettle was cooled to room temperature, the precipitate was collected by centrifugation, washed with water and ethanol several times in turn, and then dried at 150°C to obtain the reduced carbon quantum dot and indium-zinc sulfide complex. Disperse 0.4g of the above compound in 4mL of water, add 4mg of polyethylene glycol 20000 and an aqueous solution containing 8mg of chloroauric ac...

Embodiment 3

[0034] Disperse 1mmol of zinc sulfate, 1mmol of indium sulfate and 15mmol of dimethyl sulfoxide in a mixed solution of 15mL of ethanol, 20mL of acetone and 45mL of water, add 0.8mL of 1-butyl-3-methylimidazole bromide, and then add 2.1mL The ethanol solution of carbon quantum dots with a concentration of 100 mg / mL was stirred for 30 min to obtain a uniform and transparent mixed solution. The mixed solution was transferred to a reaction kettle, and then placed in a microwave hydrothermal synthesizer for microwave hydrothermal treatment at 80° C. for 5 hours. The power of the microwave hydrothermal synthesizer was 100 W. After the reaction kettle was cooled to room temperature, the precipitate was collected by centrifugation, washed with water and ethanol several times in sequence, and then dried at 30°C to obtain the reduced carbon quantum dot and indium zinc sulfide complex. Disperse 0.1g of the above compound in 10mL of water, add 10mg of polyethylene glycol 400 and an aqueou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com