Ternary compound optical catalyst and preparation method therefor and application thereof

A photocatalyst and ternary composite technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low effective absorption efficiency, low photocatalytic activity, short photocatalytic life, etc. , to achieve enhanced photocatalytic performance, simple operation method, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

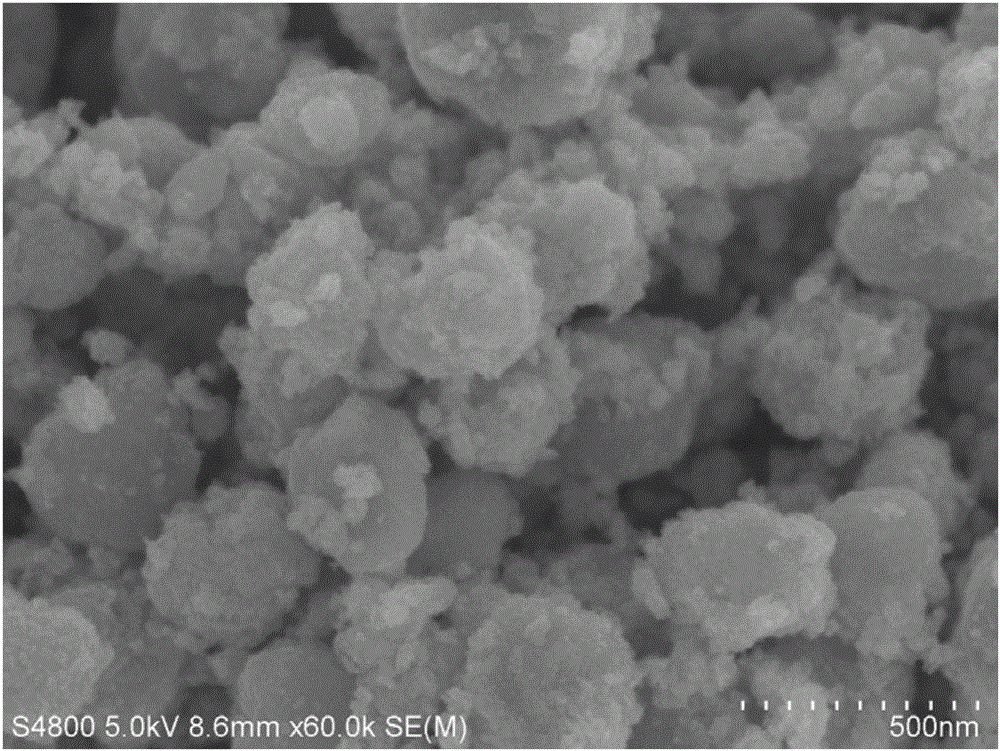

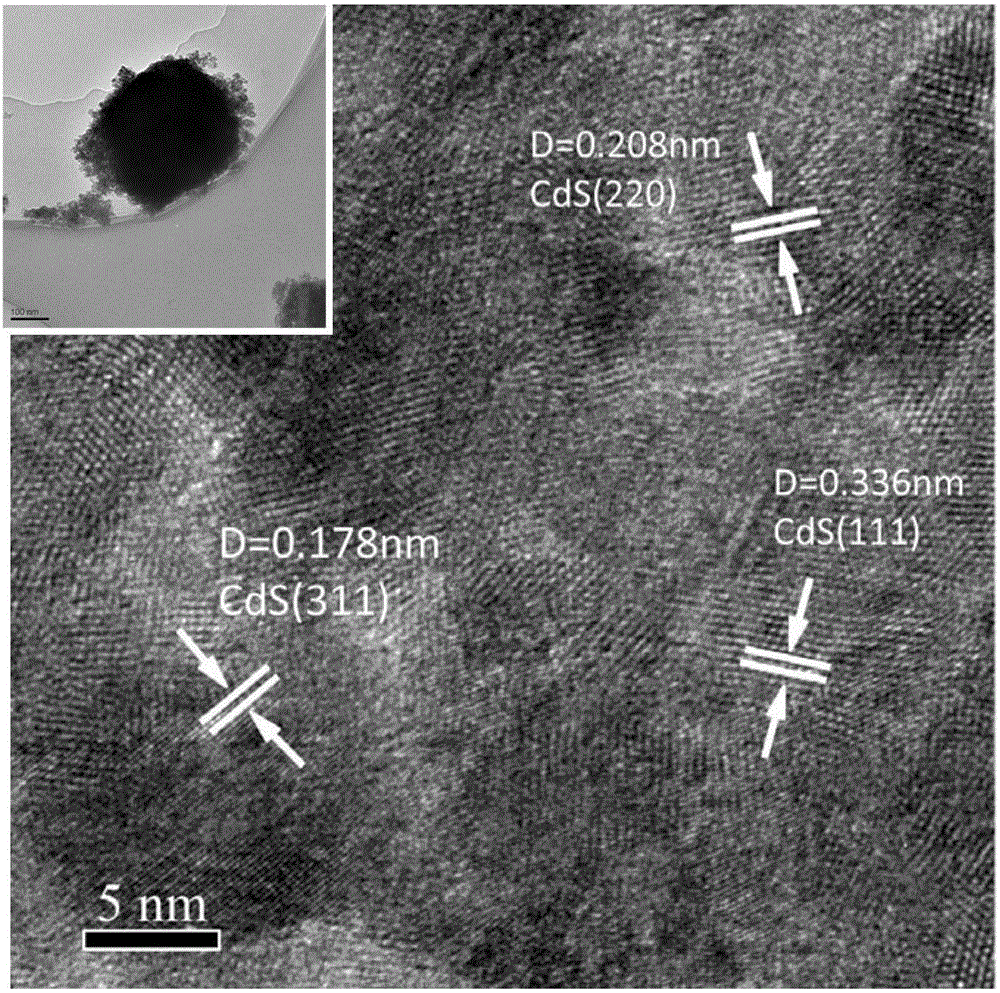

[0027] The present embodiment provides a kind of preparation method of titanium dioxide graphene-cadmium sulfide ternary composite photocatalyst, it comprises the following steps:

[0028] 1) Use the improved Hummers method to obtain neutral graphite oxide through dialysis and drying, then dissolve 1 mg of graphite oxide in 80 ml of dimethyl sulfoxide (DMSO) solution, and obtain a clear graphene oxide solution through ultrasonic dispersion;

[0029] 2) Add 17.6ml of isopropyl titanate (95%) dropwise into absolute ethanol and keep stirring, then add dropwise 3.2ml of 0.1M potassium chloride aqueous solution, stir the mixed solution at room temperature for 15 minutes, and then let it stand Aging for 18 hours, filtering the reaction solution, then repeatedly washing with ethanol, and drying to obtain titanium dioxide precursor nanospheres;

[0030] 3) taking step 2) and dissolving all the titanium dioxide precursor nanospheres obtained by the reaction in step 1) in the graphene o...

Embodiment 2

[0039] This example is roughly the same as Example 1, except that the mass of chromium acetate in step 4) is 96 mg, that is, the mass ratio of chromium acetate to titanium dioxide precursor is 1:1, and its structural properties and photolysis water hydrogen production efficiency Similar to Example 1.

Embodiment 3

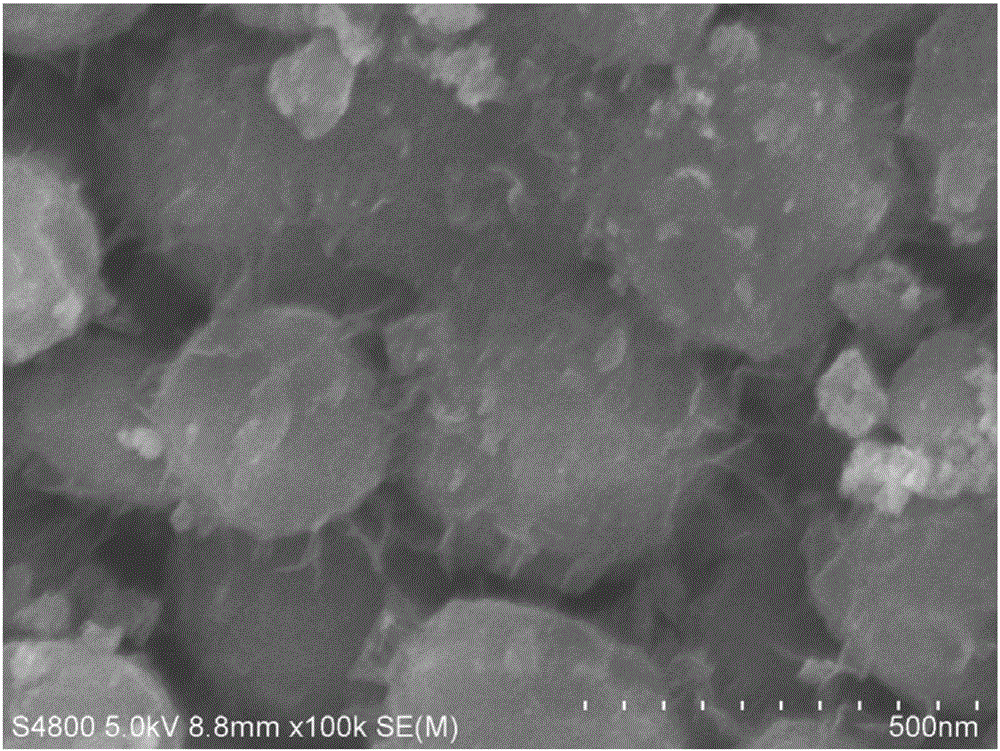

[0041] This embodiment is roughly the same as Example 1, except that the quality of chromium acetate in step 4) is 288 mg, that is, the mass ratio of chromium acetate and titanium dioxide precursor is 3:1, and its product structure is the same as that of Example 1, 2 The difference is that the cadmium sulfide layer on the surface of titanium dioxide is thicker, and there are a small amount of scattered cadmium sulfide particles that are not attached to titanium dioxide. Its photocatalytic performance is similar to Example 1. It shows that although the amount of cadmium sulfide in the product has increased, since the excess cadmium sulfide particles are not combined with titanium dioxide and graphene, the hydrogen production efficiency of this part is extremely low, so the overall hydrogen production efficiency has not been significantly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com