Monoatomic catalyst and preparation method thereof, and application of monoatomic catalyst in photolysis of water to produce hydrogen

A technology for catalysts and water to produce hydrogen, applied in chemical instruments and methods, physical/chemical process catalysts, nanotechnology for materials and surface science, etc., can solve the problems of low utilization rate of precious metals, easy agglomeration and deactivation, single atom loading Low-level problems, to achieve the effect of improving low single-atom loading, high hydrogen production efficiency, and improving the effect of photocatalytic hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1 Preparation of cadmium sulfide nanowires

[0051] 40mg Cd(NO 3 ) 2 4H 2 Mix O and 28mg thiourea, add 10mL ethylenediamine, stir well, place in a 20mL polytetrafluoroethylene reactor, react at 120-200°C for 24 hours, cool to room temperature, filter, wash with water and ethanol, and dry , to obtain cadmium sulfide nanowire products.

Embodiment 2

[0052] The preparation example of embodiment 2 single atom catalyst Pt&CdS

[0053] Disperse 50 mg of cadmium sulfide nanowires in an aqueous solution of chloroplatinic acid, stir and react for 2-4 hours at 70-90 ° C to obtain a suspension, filter to obtain a solid precursor, wash with water and ethanol, and dry the obtained The precursor was heated to 130-150°C in an argon atmosphere, kept for two hours, and then cooled down to room temperature naturally to obtain platinum single-atom catalysts Pt&CdS supported by cadmium sulfide nanomaterials.

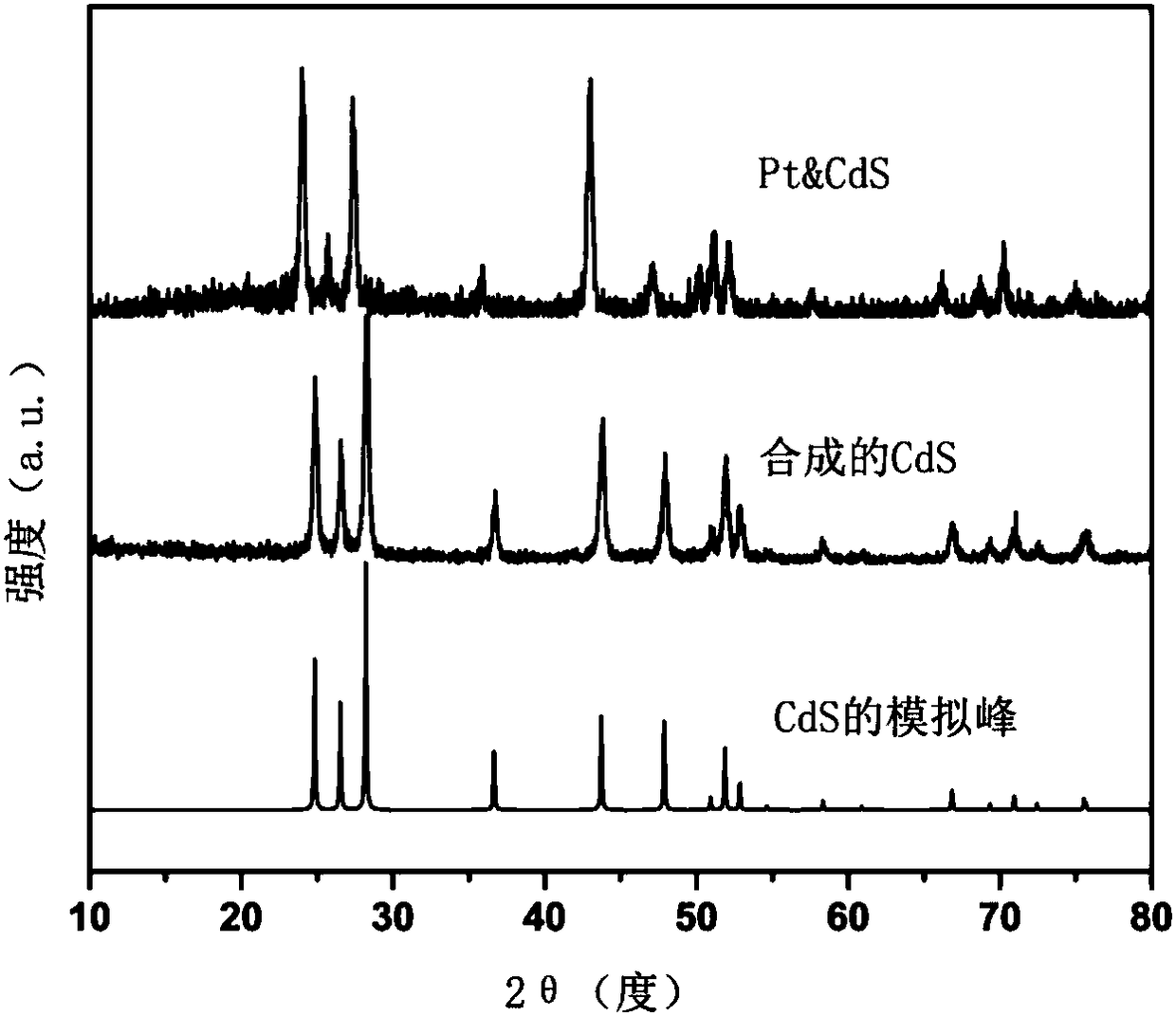

[0054] figure 1 It is the powder picture of cadmium sulfide nanowires before and after loading platinum single atoms, which proves that the loading process does not cause damage to the crystal structure of cadmium sulfide.

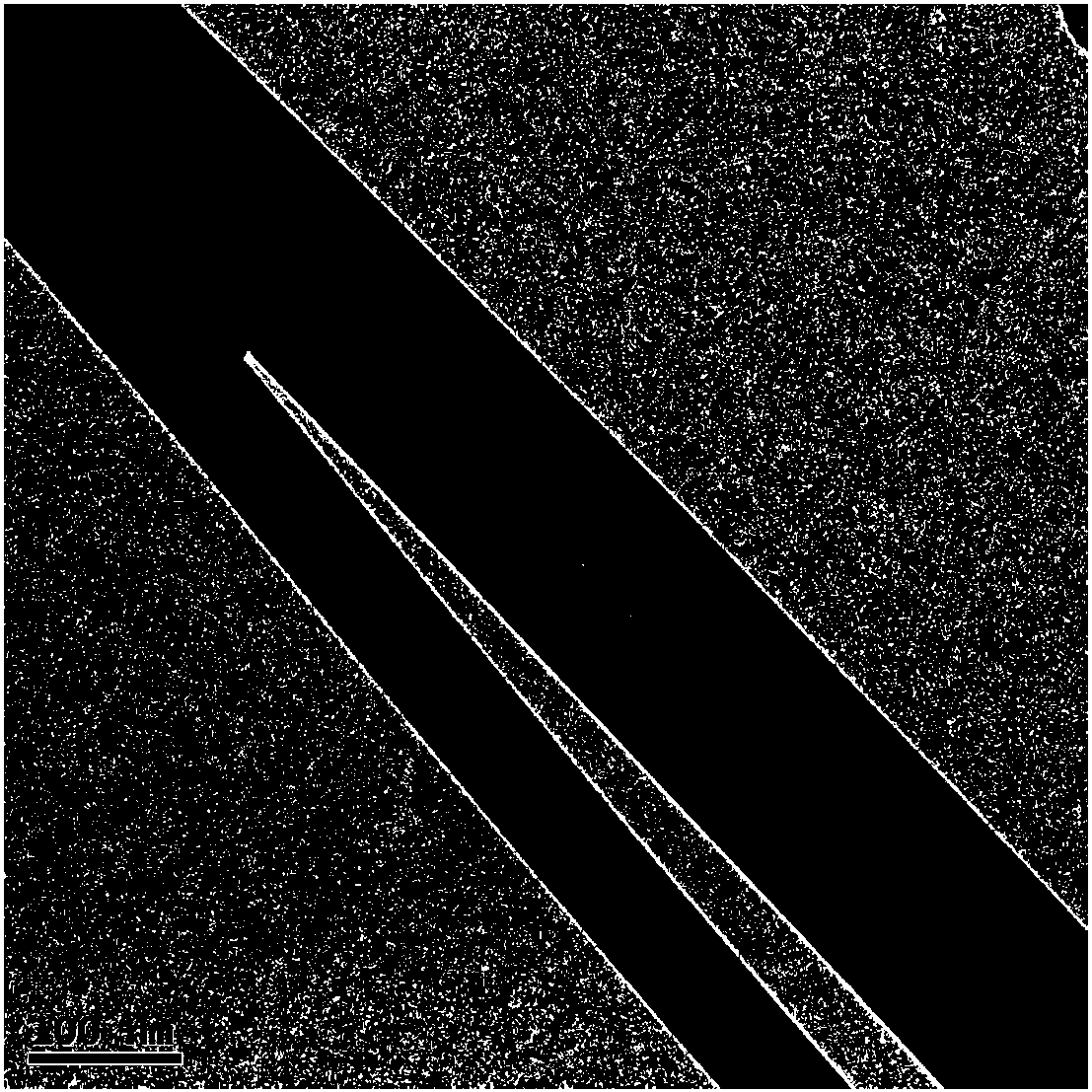

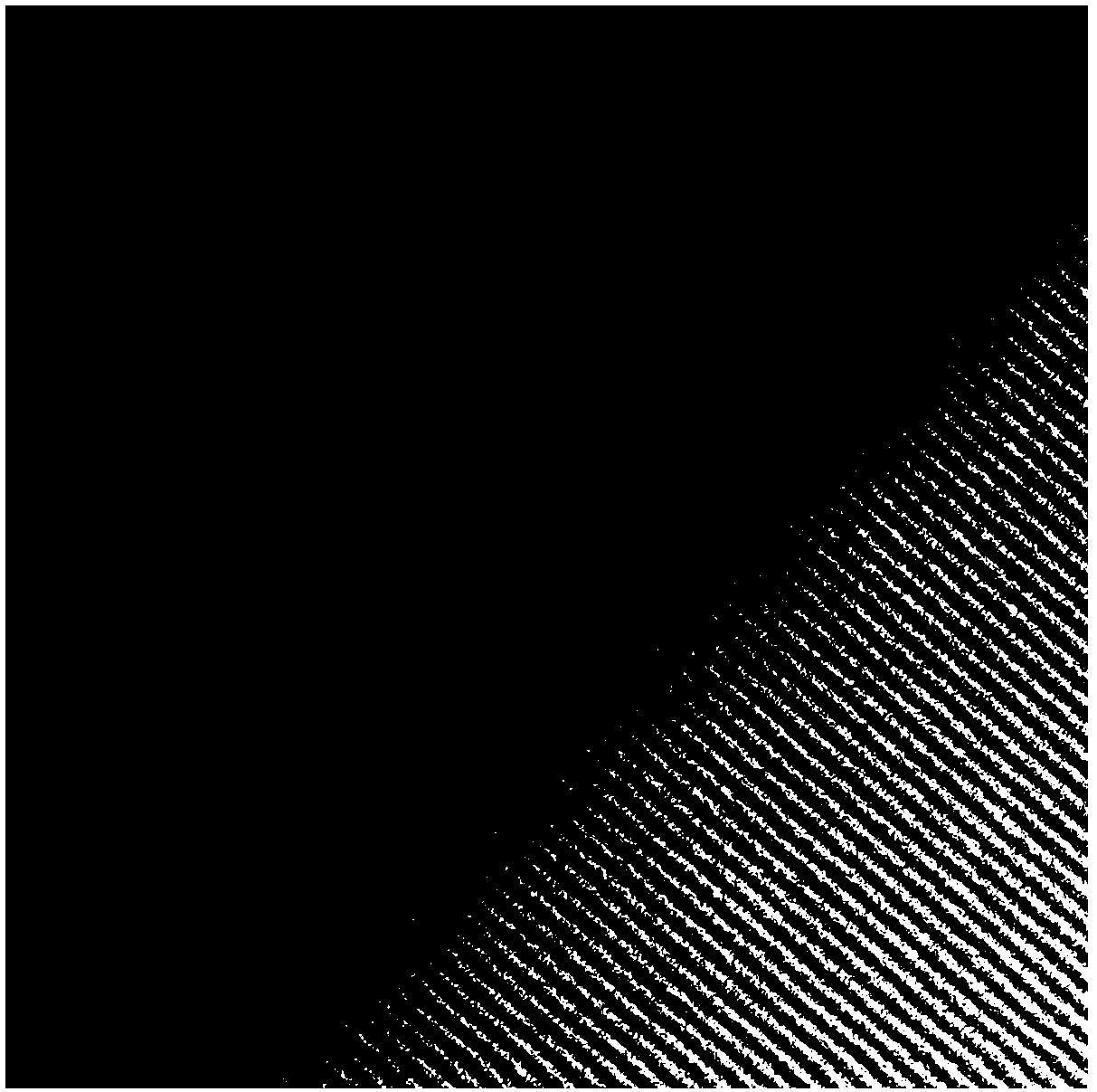

[0055] figure 2 The transmission electron microscope pictures taken under bright field for Pt&CdS, due to the low resolution of the transmission electron microscope, no platinum atoms can be observed, and it p...

Embodiment 3

[0057] Example 3 Test of the hydrogen production rate of the single-atom catalyst Pt&CdS as a photocatalyst for photolysis of water to produce hydrogen

[0058] Add 90 milliliters of deionized water, 10 milliliters of lactic acid, and 100 milligrams of sample to the reaction kettle, cover the reaction kettle, evacuate with a vacuum pump while stirring until no bubbles are produced in the liquid, and irradiate with a 300W xenon lamp (uvcut 420 filter) . Sampling once per hour, sampling six times, record the peak area, calculate the hydrogen production and hydrogen production rate. In the present invention, the hydrogen production rate of the photocatalyst Pt&CdS is 47.41mmol h -1 g -1 .

[0059] Figure 4 In order to compare the hydrogen production rate of nanowire cadmium sulfide and catalyst Pt&CdS in aqueous lactic acid solution, the hydrogen production rate of cadmium sulfide is 1.02mmol h -1 g -1 , the hydrogen production rate of catalyst Pt&CdS is 47.41mmol h -1 g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com