Modified composite bismaleimide resin prepolymer, resin composition, and semi-cured sheet and laminated board produced therewith

A composite bismaleimide resin, composite bismaleimide technology, applied in synthetic resin layered products, applications, household appliances and other directions, can solve the problem of the distribution of diphenylmethane bismaleimide resin. It can solve the problems of uniformity, fast reaction and poor manufacturability, so as to achieve the effect of solving the problems of reaction control and manufacturability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example

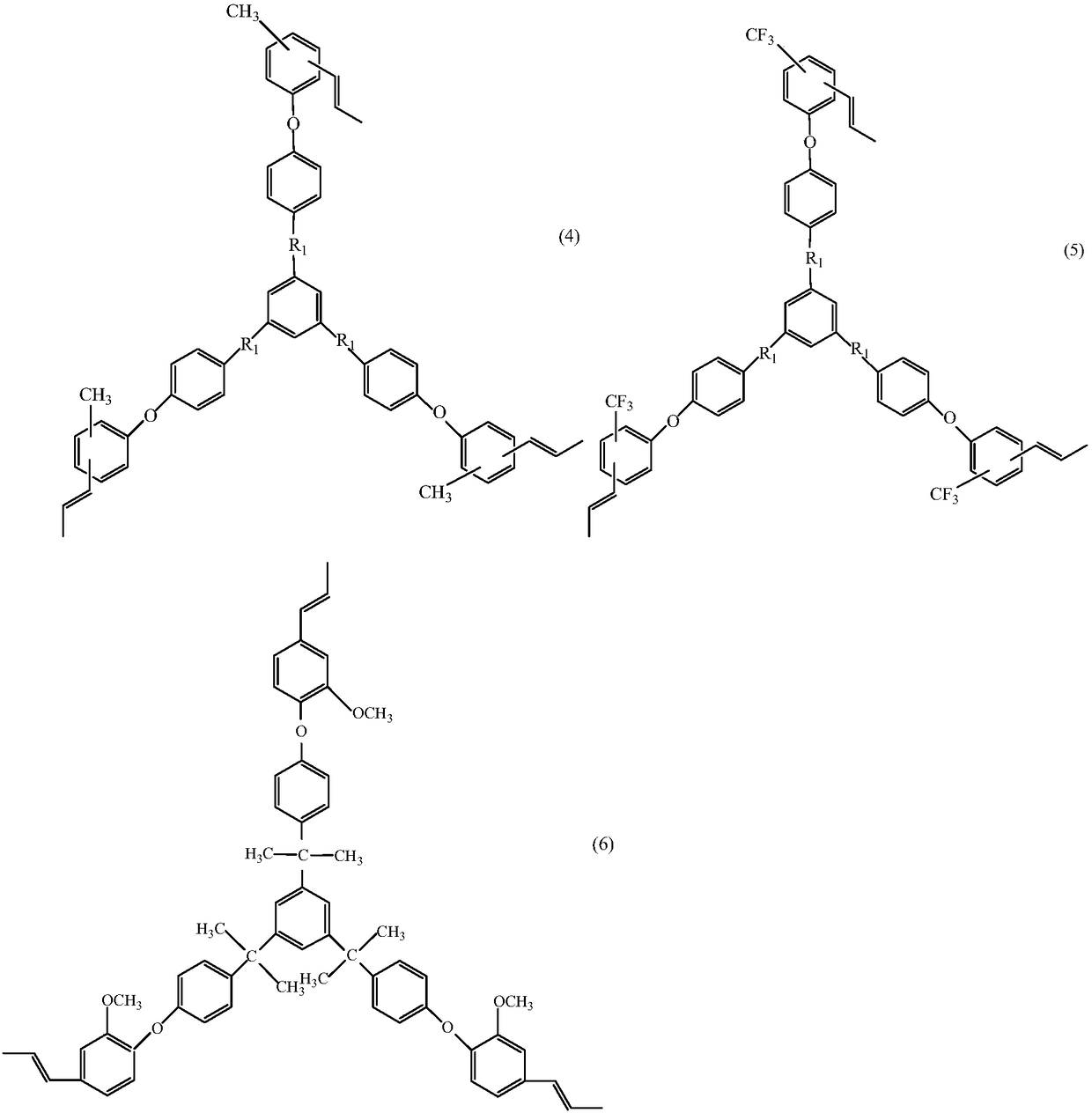

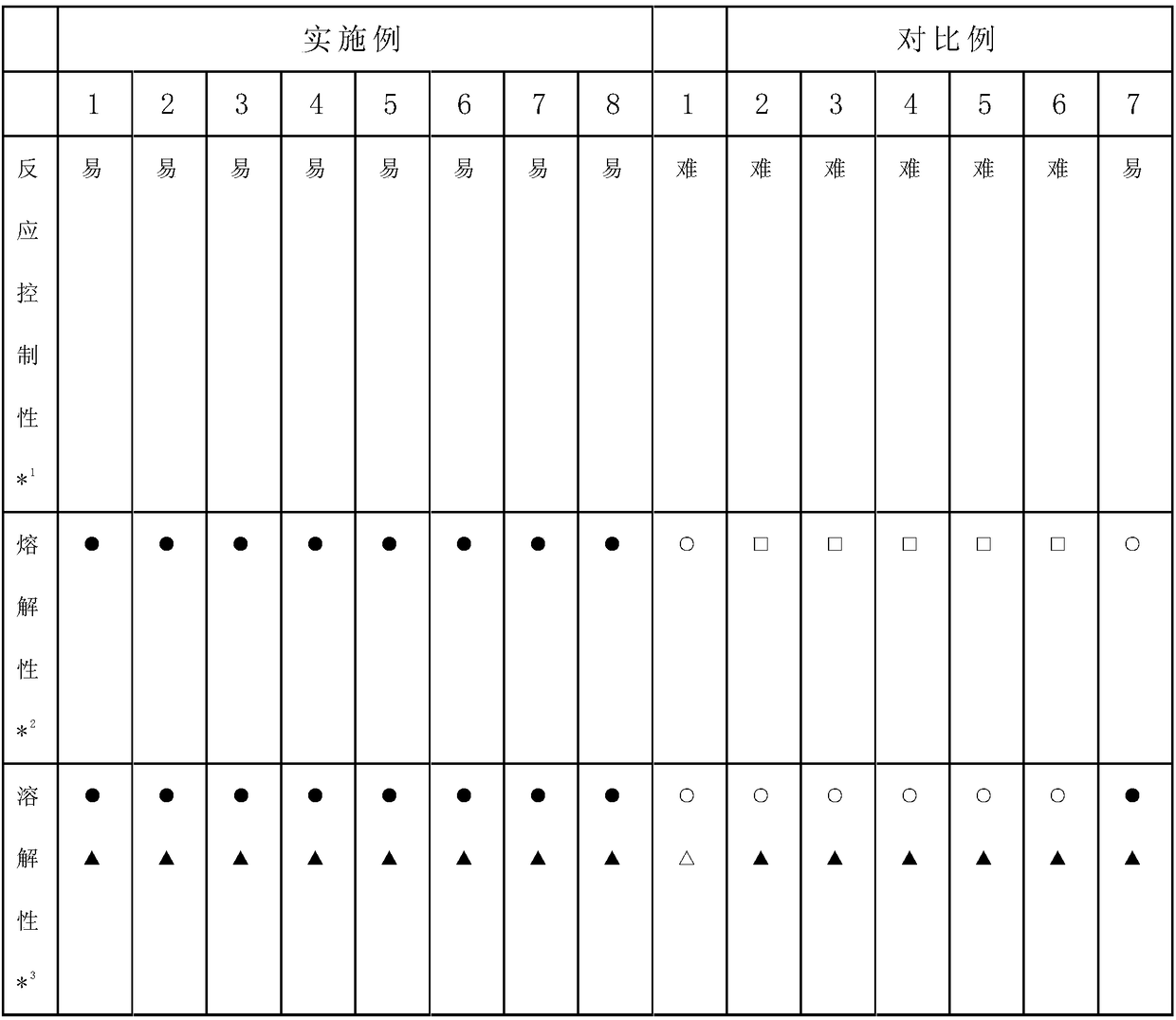

[0060] Add a certain amount of N,N-dimethylformamide (or N,N-dimethylacetamide) solvent into a flask equipped with a thermometer, a reflux condenser, a vacuum concentration device and a stirring device, and then three The molar ratio of functional fluoroketone and allylphenol is 1:(3-4) and a certain amount of accelerator are respectively added to the flask and mixed. Then the temperature of the solution was raised to 160-170° C., and the reaction was maintained at this temperature for 5-10 hours to obtain a crude product, which was filtered. Then the filtrate is cooled and precipitated, filtered, washed with water, and then dried to obtain the desired tripenylphenoxy compound.

[0061] The tripenylphenoxy compounds of the structural formulas (4), (5) and (6) were synthesized by the above method respectively.

[0062]

[0063] The structural formula (1) described in the following examples and comparative examples and (a) to (g) in the structure all refer to the chemical fo...

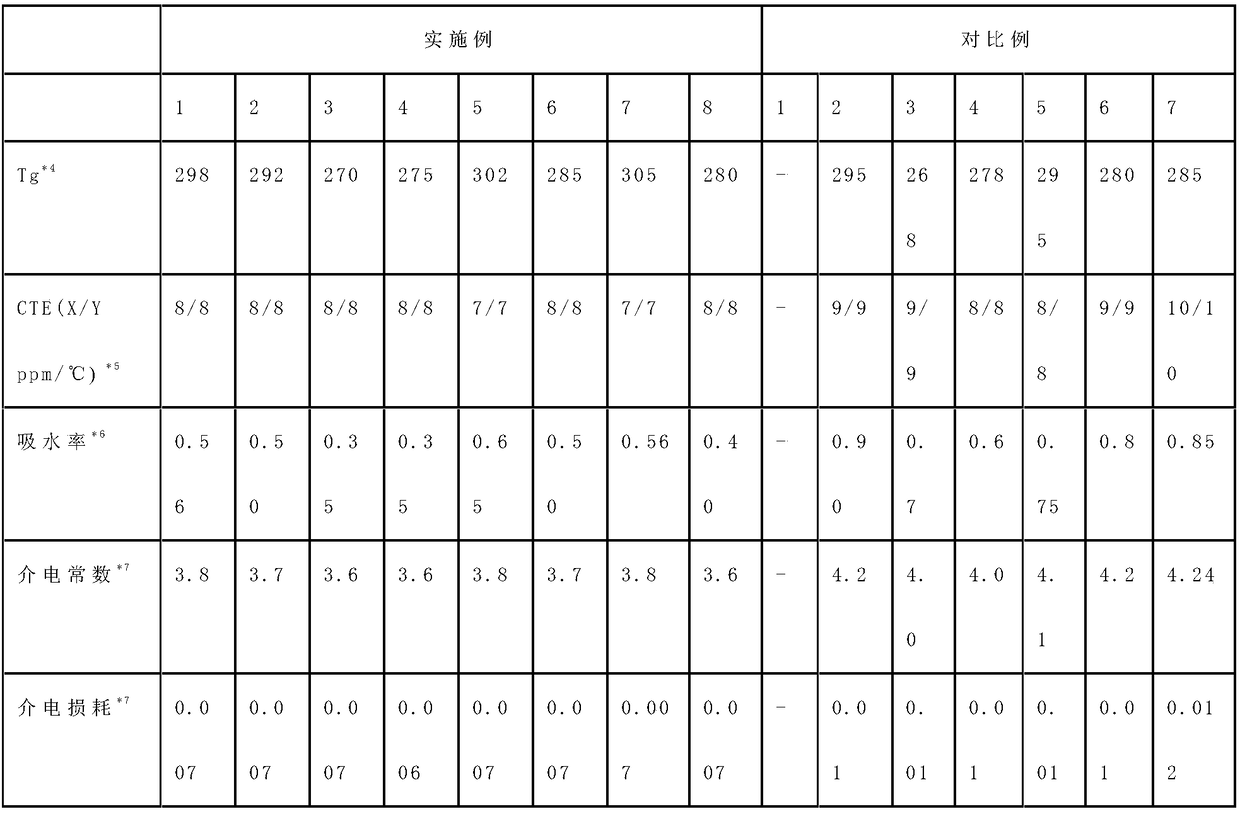

Embodiment 1

[0069] Take structure (a) and (d) bismaleimide (wherein the mass ratio of structure (a) and (d) is 50:30) 100g in structural formula (1), propenyl phenoxy compound (structural formula (4)) 60g, put into a 500ml beaker, and react at 145°C for 1.5h to obtain a modified composite bismaleimide prepolymer. Get this bismaleimide prepolymer of 60g after cooling and add appropriate amount of acetone to dissolve. After the modified bis-horse resin is completely dissolved, add 15g of cyanate (the selected cyanate resin is: BA-3000S or CE01PS), 15g of biphenyl epoxy resin (NC3000H, epoxy equivalent 288g / mol), 10g containing Phosphorus phenolic resin (XZ92741), 0.05g 2-methyl-4-ethylimidazole, 100g spherical silica (average particle size 0.7 micron, SFP-30M, DENKA), stirred and mixed evenly to obtain glue.

[0070] The glue is dipped and coated on E glass fiber cloth (2116, unit weight is 104g / m 2 ) and baked in an oven at 160°C for 5 minutes to obtain a prepreg with a resin content of ...

Embodiment 2

[0075] Take structure (a) and (d) bismaleimide (wherein the mass ratio of structure (a) and (d) is 50:15) 100g in structural formula (1), propenyl phenoxy compound (structural formula (4)) 60g, put into a 500ml beaker, and react at 145°C for 2.0h to obtain a modified composite bismaleimide prepolymer. Get this bismaleimide prepolymer of 60g after cooling and add appropriate amount of acetone to dissolve. After the modified bis-horse resin is completely dissolved, add 15g of cyanate (the selected cyanate resin is: BA-3000S or CE01PS), 15g of biphenyl epoxy resin (NC3000H, epoxy equivalent 288g / mol), 10g containing Phosphorus phenolic resin (XZ92741), 0.05g 2-methyl-4-ethylimidazole, 100g spherical silica (average particle size 0.7 micron, SFP-30M, DENKA), stirred and mixed evenly to obtain glue.

[0076] The preparation methods of the prepreg and the copper-clad laminate are the same as in Example 1. The preparation method of the interlayer insulating film is the same as

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com