Method for preparing battery cathode active substance calcium zincate

A technology of active material and battery negative electrode, which is applied in the field of preparation of calcium zincate, an active material of battery negative electrode, can solve the problems of reduced high current working capacity, low power characteristics, and reduced real porosity of electrodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

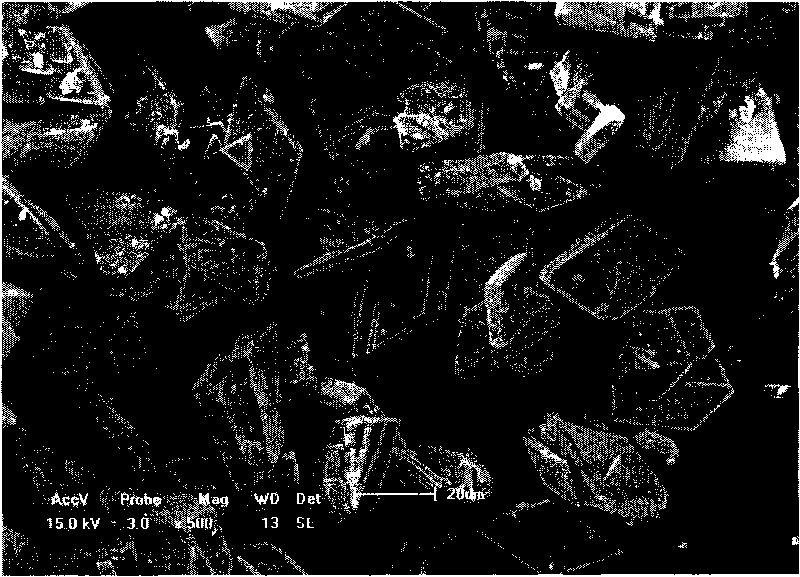

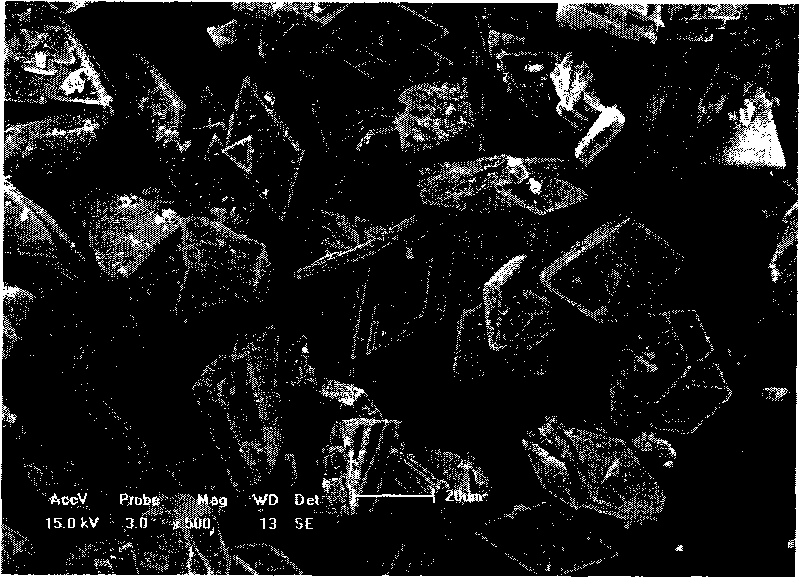

Image

Examples

Embodiment 1

[0027] Embodiment 1: Weigh 578g of analytically pure CaCl with a content of not less than 96% 2 Put it in a clean container, add purified water to 4000ml. Stir until the slightly yellow solution is transparent and clear, cover it for later use; weigh 1392g of analytically pure ZnCl with a content of not less than 98% 2 Put it into a clean container, add pure water to 10000ml, stir until the milky white solution is transparent and clear, cover it for later use; mark the container with a scale of 8000ml, rinse it, rinse it with pure water, and dry it for later use; weigh 1333g Put ≥96% analytically pure NaOH into a container, add pure water to 8000ml, and stir until the solution is clear; use n-hexanol and OP-10 according to the ratio of n-hexanol: OP-10: cyclohexane = 800mL: 1200mL: 4000mL After mixing with a small mixer, add an appropriate amount of cyclohexane, and stir well to make an emulsion; pour 8000ml of 4mol / L NaOH solution into a 30000ml capacity mixer, start stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com