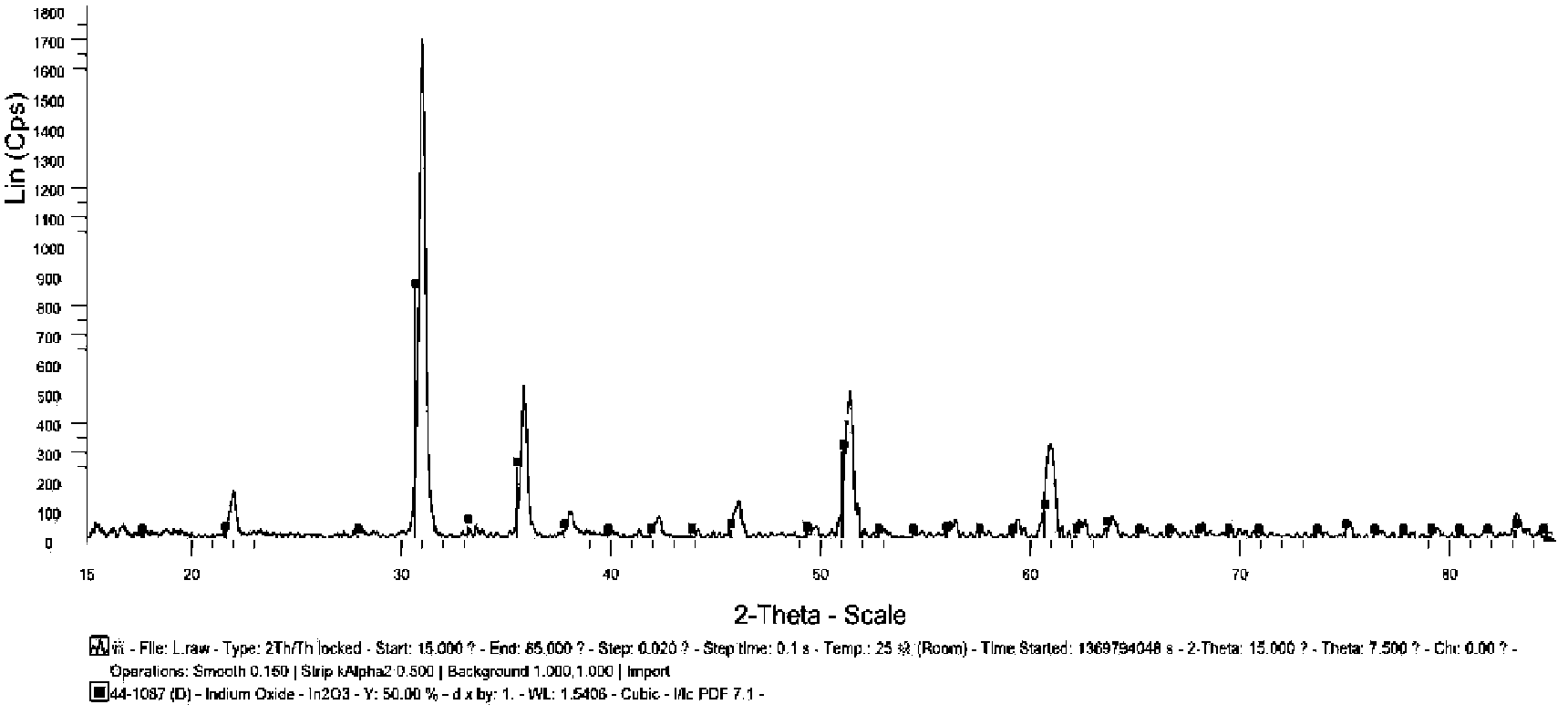

Preparation method of blue nanometer tin indium oxide powder

A nano-indium tin oxide and blue technology, applied in tin oxide, chemical instruments and methods, nanotechnology, etc., can solve the problems of solvent waste, unstable reaction pressure, poor crystallinity, etc., and achieve cost saving and simple equipment requirements , Conducive to the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of blue nano indium tin oxide powder, comprising the following steps:

[0028] 1) Add InCl 3 and anhydrous SnCl 4 It is 0.2mol / L solution that the concentration of metal ion is mixed with distilled water, then the ammoniacal liquor that molarity is 0.2mol / L is dissolved in distilled water to make alkaline solution, then the described alkaline solution that makes is with the concentration of 10ml / min Add dropwise to the 0.2mol / L solution at a dropping rate, and keep stirring, control the reaction temperature to 60°C, stop dropping when PH=7.1, continue to react for 30 minutes, and prepare a white indium tin oxide precursor;

[0029] 2) Wash the white indium tin oxide precursor prepared in step 1) three times with water and twice with ethanol, and then put it into a drying oven for drying at a temperature of 60°C. Grinding to obtain intermediate product B;

[0030] 3) Put the intermediate product B obtained in step 2) into a crucible, and then put ...

Embodiment 2

[0035] A preparation method of blue nano indium tin oxide powder, comprising the following steps:

[0036] 1) Add InCl 3 and anhydrous SnCl 4 It is mixed with distilled water to make a metal ion concentration of 0.2mol / L solution, then the urea with a molar concentration of 1mol / L is dissolved in distilled water to make an alkaline solution, and then the alkaline solution made is dripped at 50ml / min Add it dropwise to the 0.2mol / L solution at an accelerated rate, and keep stirring, control the reaction temperature to 60°C, stop the dropwise addition when PH=7.1, and continue the reaction for 30 minutes to prepare a white indium tin oxide precursor;

[0037] 2) Wash the white indium tin oxide precursor prepared in step 1) three times with water and twice with ethanol, and then put it into a drying oven for drying at a temperature of 80°C. Grinding to obtain intermediate product B;

[0038] 3) Put the intermediate product B obtained in step 2) into a crucible, and then put it...

Embodiment 3

[0043] A preparation method of blue nano indium tin oxide powder, comprising the following steps:

[0044] 1) Add InCl 3 and anhydrous SnCl 4 It is 0.2mol / L solution that metal ion concentration is mixed with distilled water, then the aqueous solution of ammonium bicarbonate that molar concentration is 0.5mol / L is dissolved in distilled water to make alkaline solution, then the described alkaline solution that makes is with Add dropwise at a rate of 10-50ml / min into the solution with a concentration of 0.2mol / L, and keep stirring, control the reaction temperature at 60°C, stop dropping when PH=7.1, continue to react for 30 minutes, and obtain white oxide Indium tin precursor;

[0045] 2) Wash the white indium tin oxide precursor prepared in step 1) three times with water and twice with ethanol, and then put it into a drying oven for drying at a temperature of 70°C. Grinding to obtain intermediate product B;

[0046] 3) Put the intermediate product B obtained in step 2) int...

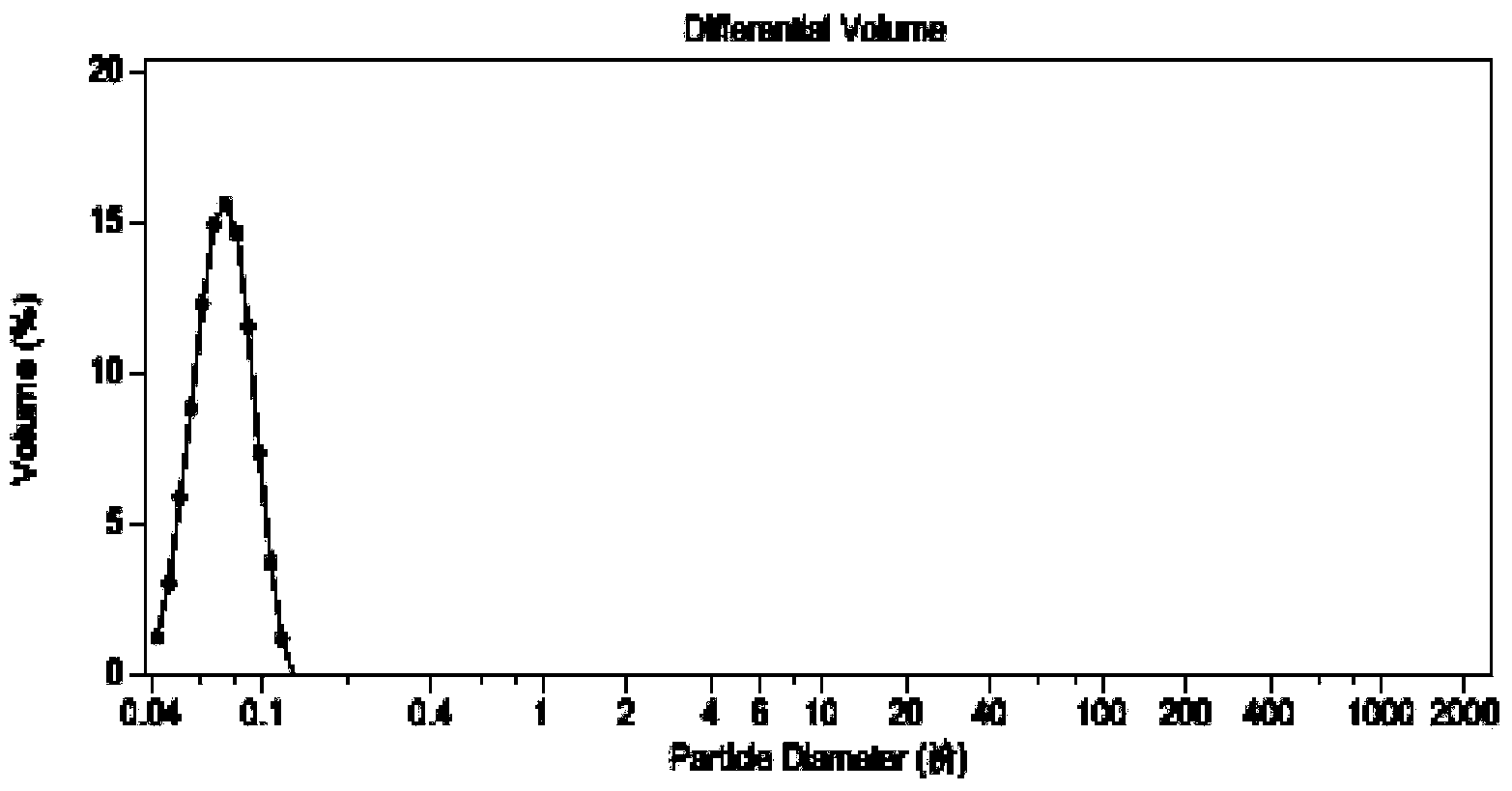

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com