Film solar cell and preparation method thereof

A solar cell and thin film technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as increasing the cost of batteries, and achieve the effects of avoiding recombination, improving photoelectric conversion efficiency, and increasing short-circuit current and open-circuit voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

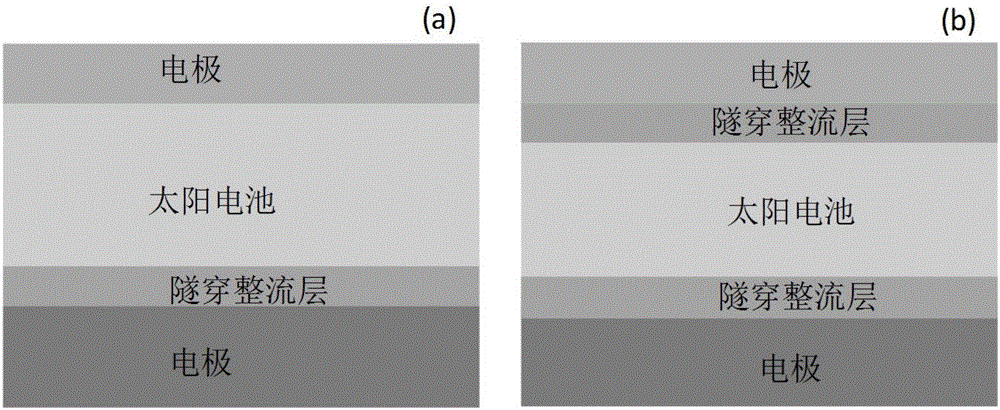

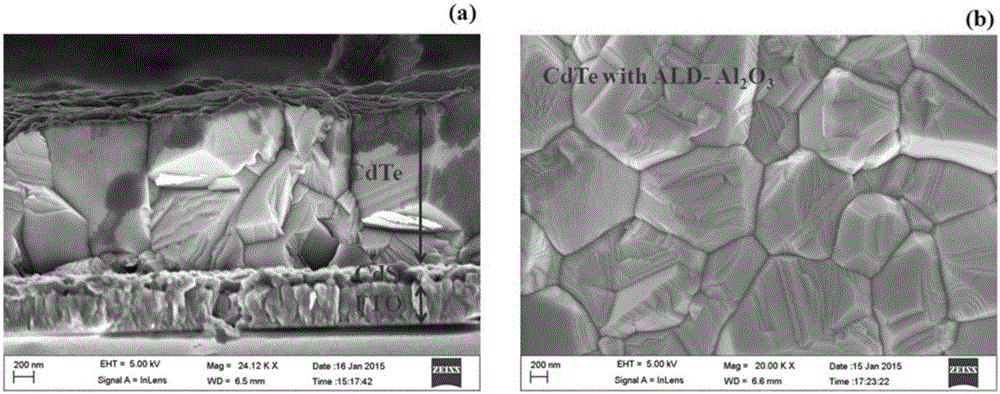

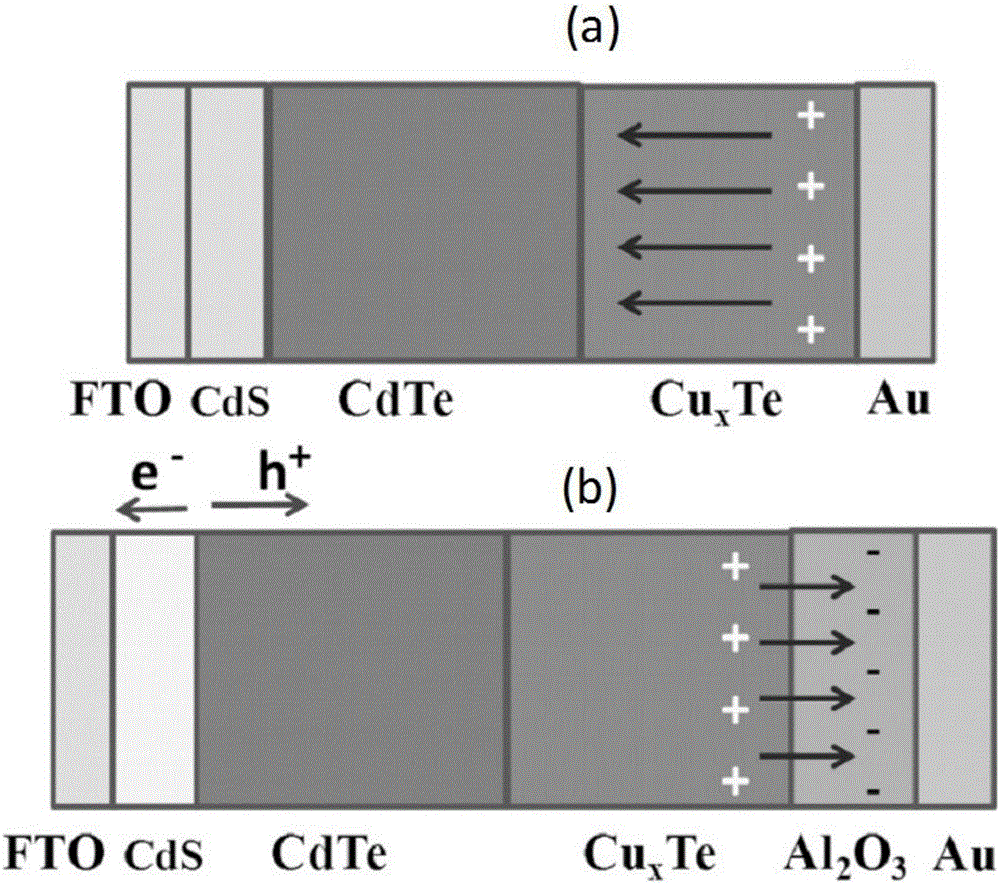

[0033] In this example, a cadmium telluride thin film solar cell was used for the experiment, and Al was formed on the surface of CdTe by atomic layer deposition 2 O 3 The tunneling rectification layer of this example is the tunneling rectification layer, which is disposed between the semiconductor layer and the back electrode layer.

[0034] The basic preparation process is as Image 6 As shown, a sputtering method is used to prepare a transparent front electrode layer FTO in sequence on a glass substrate, and the thickness can be 300 nm to 1 μm. In this example, a transparent electrode layer with a thickness of 500 nm is specifically prepared; then the n-type transition layer CdS is sputtered, and the thickness can be 100 -200nm. In this example, an n-type transition layer with a thickness of 145nm was specifically prepared, and a p-type light-absorbing layer CdTe film was prepared by vacuum evaporation deposition of CSS, and then CdCl was sequentially performed 2 Annealing, NP ...

Embodiment 2

[0038] This example uses cadmium telluride thin-film solar cells for testing. The difference from Example 1 is that this example will tunnel through the rectifier layer Al 2 O 3 The layer is provided between the semiconductor layer and the front electrode layer.

[0039] The transparent electrode layer FTO is prepared sequentially by sputtering method on the glass substrate. The thickness of this example can be 300nm~1μm. In this example, a transparent electrode layer with a thickness of 500nm is prepared; then Al is formed on the surface of the front electrode by atomic layer deposition 2 O 3 The tunneling rectifier layer of this example, the specific tunneling layer preparation process can refer to the specific process of Example 1, the thickness of the tunneling layer is 1nm; then the n-type transition layer CdS is sputtered, the thickness can be 100-200nm In this example, an n-type transition layer with a thickness of 145 nm was specifically prepared, and a p-type light-absorbi...

Embodiment 3

[0043] In this example, a copper indium gallium selenium thin film solar cell is used for the experiment. The physical vapor deposition method is mainly used to form cuprous oxide Cu on the back electrode of the copper indium gallium selenium thin film solar energy. 2 The O layer is the tunneling rectification layer of this example; the tunneling rectification layer is arranged between the semiconductor layer and the back electrode layer.

[0044] Sputtering on the glass substrate. The metal back electrode layer Mo is prepared by sputtering on the glass substrate in sequence. The thickness of this example can be 500nm~1μm. In this example, a metal electrode layer with a thickness of 1μm is prepared; the deposition temperature of the tunneling layer is 200℃. The background vacuum is 1.0×10 -3 Below Pa, pass argon Ar as the sputtering gas, and a small amount of oxygen as the reactive gas. (1) Under the action of the alternating electric field applied by the RF power supply to the sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com