Perovskite solar cell based on metal nanoparticle interface modification and preparation method of perovskite solar cell

A technology of metal nanoparticles and solar cells, which is applied in the field of solar cells, can solve problems such as insufficient absorption, and achieve the effects of improved photoelectric conversion efficiency, high fill factor, and high photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

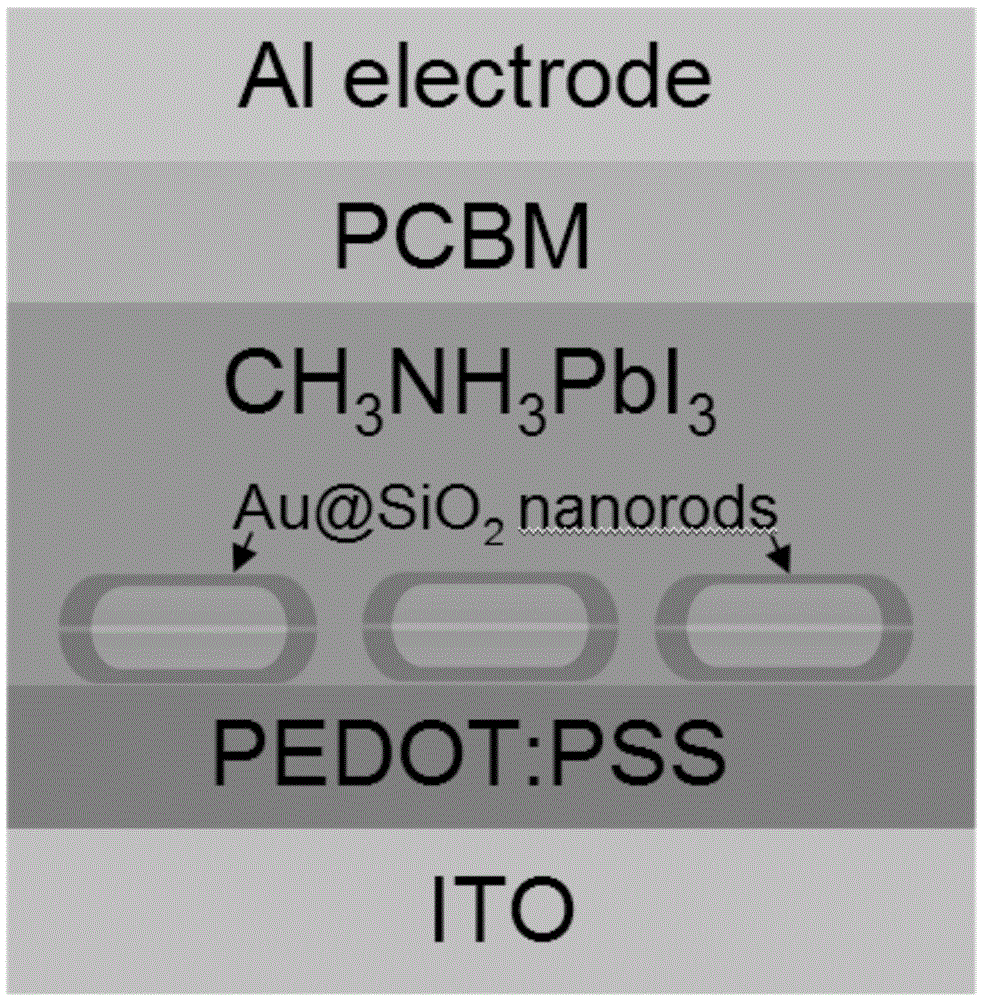

[0026] according to figure 1 Schematic diagram of perovskite solar cell device structure for device fabrication.

[0027] Commercial ITO was sonicated in an ultrasonic cleaner for 15 minutes through acetone, detergent, deionized water and isopropanol, then dried with nitrogen flow, and then treated with ozone for 20 minutes.

[0028] The cleaned and ozone-treated ITO glass was placed on a spin coater, and spin-coated at a speed of 3000 rpm to prepare a hole transport layer PEDOT:PSS, and then annealed on a 150-degree heating platform for 15 minutes.

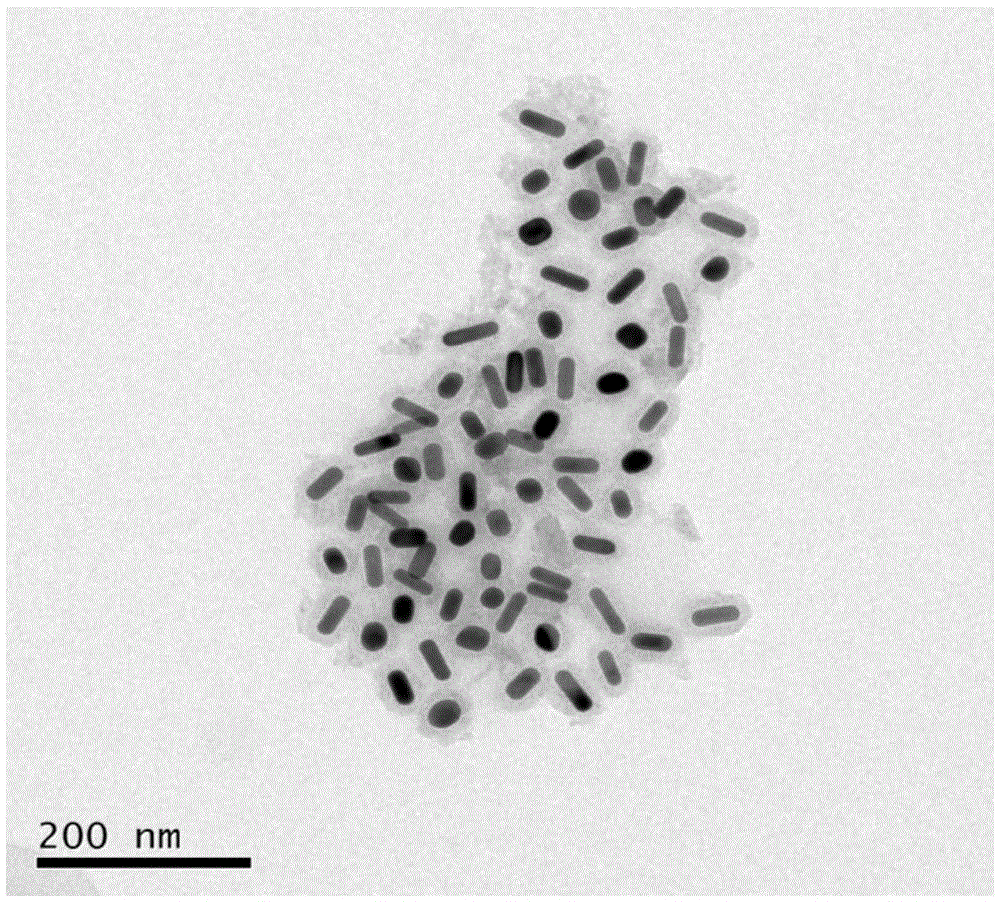

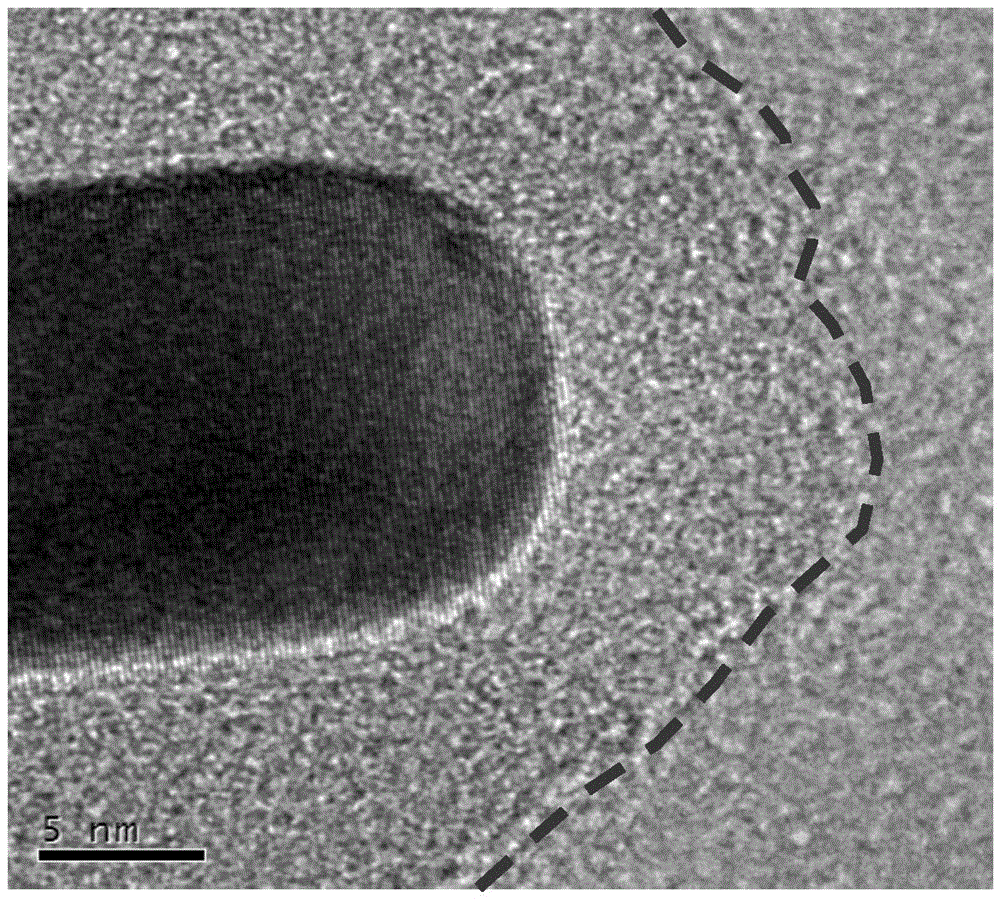

[0029] AuSiO 2 Nanoparticles were made into ethanol solutions with concentrations of 0.032pM, 0.047pM and 0.095pM, and then ultrasonicated for 5 minutes to fully disperse, spin-coated on the PEDOT:PSS layer at a speed of 3000 rpm, and then annealed at 120 degrees for 5 minutes , prepared AuSiO 2 The morphology and size distribution of the nanoparticle layer are as follows figure 2 , image 3 and Figure 4 ; image 3 It can ...

Embodiment 2

[0038] Commercial ITO was sonicated in an ultrasonic cleaner for 15 minutes through acetone, detergent, deionized water and isopropanol, then dried with nitrogen flow, and then treated with ozone for 20 minutes.

[0039] The cleaned and ozone-treated ITO glass was placed on a spin coater, and spin-coated at a speed of 3000 rpm to prepare a hole transport layer PEDOT:PSS, and then annealed on a 150-degree heating platform for 15 minutes.

[0040] AuSiO 2 Nanoparticles were made into an ethanol solution with a concentration of 0.047pM, then ultrasonicated for 5 minutes to fully disperse, then spin-coated on the PEDOT:PSS layer at a speed of 3000 rpm, and annealed at 120 degrees for 5 minutes.

[0041] Lead bromide and methyl bromide are prepared in a molar ratio of 1:1 into a DMF solution with a concentration of 500 mg / ml, heated at 60 degrees for one hour, and then the perovskite CH 3 NH 3 PbBr 3 Spin deposition of precursor solution onto AuSiO at 4000 rpm 2 The thin layer ...

Embodiment 3

[0046] Commercial ITO was sonicated in an ultrasonic cleaner for 15 minutes through acetone, detergent, deionized water and isopropanol, then dried with nitrogen flow, and then treated with ozone for 20 minutes.

[0047] The cleaned and ozone-treated ITO glass was placed on a spin coater, and spin-coated at a speed of 3000 rpm to prepare a hole transport layer PEDOT:PSS, and then annealed on a 150-degree heating platform for 15 minutes.

[0048] AuSiO 2 Nanoparticles were made into an ethanol solution with a concentration of 0.047pM, then ultrasonicated for 5 minutes to fully disperse, then spin-coated on the PEDOT:PSS layer at a speed of 3000 rpm, and annealed at 120 degrees for 5 minutes.

[0049] Lead chloride, lead iodide and methyl bromide are prepared in a molar ratio of 1:1:1 into a DMF solution with a concentration of 580 mg / ml, heated at 60 degrees for one hour, and then the perovskite CH 3 NH 3 PB x Cl 3-x Spin deposition of precursor solution onto AuSiO at 4000 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com