A gradient doped silicon-based heterojunction solar cell and its preparation method

A solar cell and gradient doping technology, which is applied in the field of solar cells, can solve the problems that cannot be pushed to the pn junction region to increase the photocurrent, achieve high photoelectric conversion efficiency, increase short-circuit current, and reduce losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

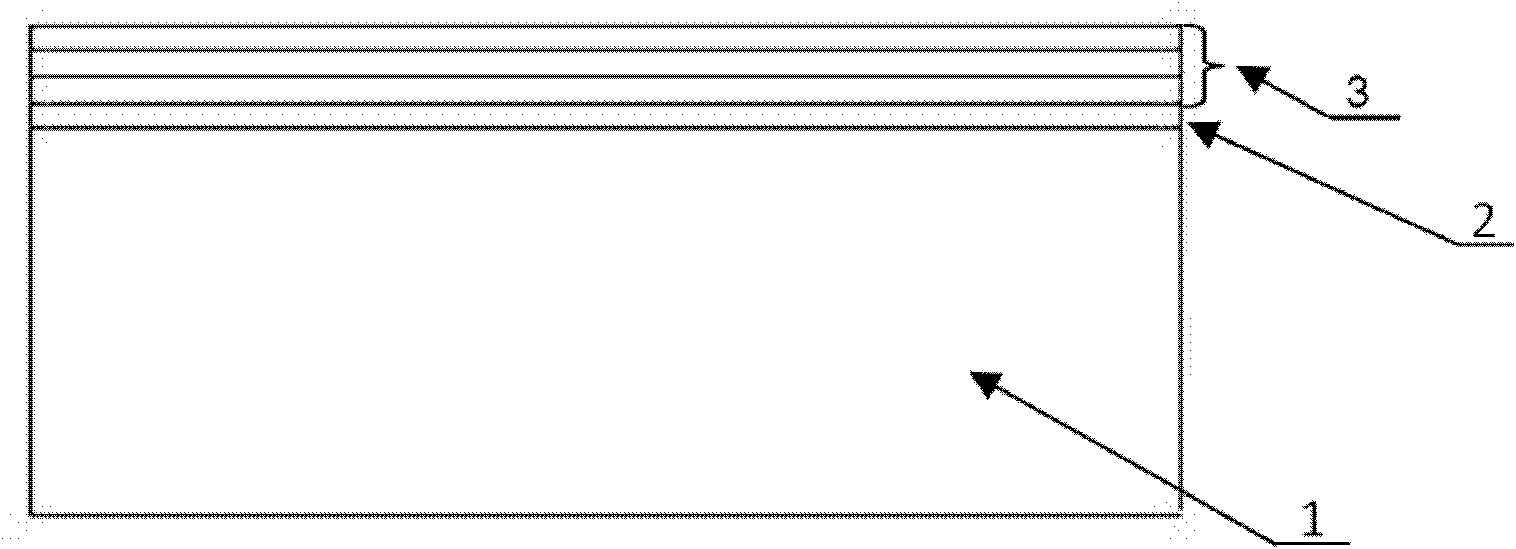

[0030](1) In this embodiment, a p-type single crystal silicon substrate Ω·cm with a resistivity of 3Ω·cm produced by zone melting is adopted, the orientation of the single crystal silicon is (100), and the thickness is 300 μm. First measure 300mL of deionized water, 300mL of ethanol and 300mL of acetone into the container to make a 1:1:1 mixed cleaning solution, and then put such figure 1 Put the single crystal silicon substrate 1 shown in the mixed cleaning solution, put the container containing the mixed cleaning solution and the substrate into an ultrasonic cleaner, and perform ultrasonic cleaning for 15 minutes. After cleaning, put the substrate into an oven to dry Drying, the oven temperature is set to 130 ° C; then the mixed solution of hydrochloric acid and hydrogen peroxide prepared according to the volume ratio of 1:1 is used to remove the metal impurities on the surface of the single crystal silicon substrate, washed with deionized water and then dried;

[0031] (2) ...

Embodiment 2

[0046] (1) The p-type monocrystalline silicon chip of resistivity 3Ω cm produced by zone melting is used as substrate, and all the other are with embodiment 1 step (1);

[0047] (2) same as step (2) in embodiment 1;

[0048] (3) same as step (3) in embodiment 1;

[0049] (4) same as step (4) in embodiment 1;

[0050] (5) Put the dried p-type single crystal silicon substrate above into the PECVD deposition chamber, and evacuate the body to 1×10 -5 Pa, the substrate temperature is heated to 185° C., and then hydrogen, silane, and phosphine gas diluted with hydrogen are introduced as reaction gases. The volume content of phosphine in the phosphine gas used is 5%, and the rest is hydrogen. The doping concentration in the doped amorphous silicon film is controlled by controlling the flow of phosphine gas, and the total flow of silane, hydrogen, and phosphine gas is controlled to be 100 sccm. First, the flow rate of silane is 5 sccm, the flow rate of hydrogen gas is 94.5 sccm, th...

Embodiment 3

[0062] (1) The n-type monocrystalline silicon chip of resistivity 3Ω cm produced by zone melting is used as substrate, and all the other are with embodiment 1 step (1);

[0063] (2) same as step (2) in embodiment 1;

[0064] (3) same as step (3) in embodiment 1;

[0065] (4) same as step (4) in embodiment 1;

[0066] (5) Put the dried n-type single crystal silicon substrate into the PECVD deposition chamber, and evacuate to 1×10 -5 Pa, the substrate temperature is heated to 200°C, then feed hydrogen and silane as reaction gas, the flow of hydrogen is 95 sccm, the flow of silane is 5 sccm, the total flow is 100 sccm, that is, the volume concentration of silane in the reaction gas is 5%, The pressure of the PECVD deposition chamber was controlled at 50 Pa. After the state was stabilized, the RF power was turned on and the power was adjusted to 50 W. The deposition was performed for 2 minutes, and then the RF power was turned off to stop the deposition. At this point the depos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com