Organic/inorganic hybrid solar cell and preparation method thereof

A solar cell, hybrid technology, applied in the fields of nanomaterials and energy, to achieve the effects of increasing open circuit voltage, performance, and short circuit current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

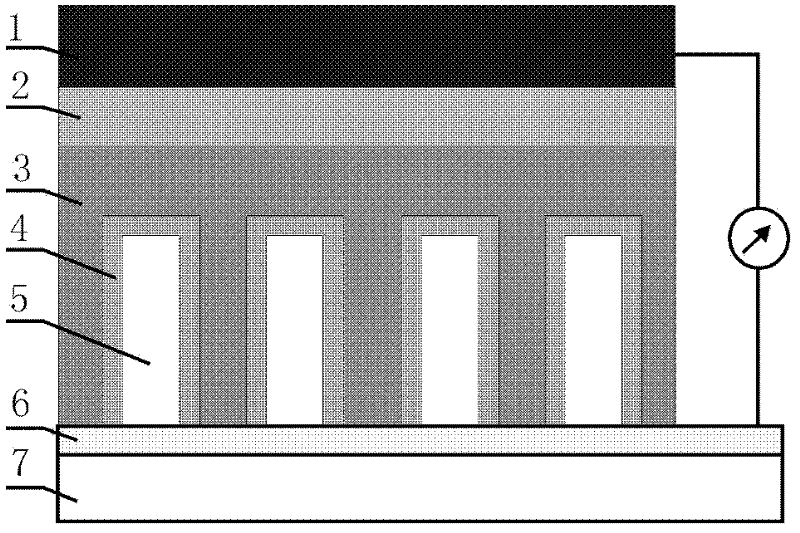

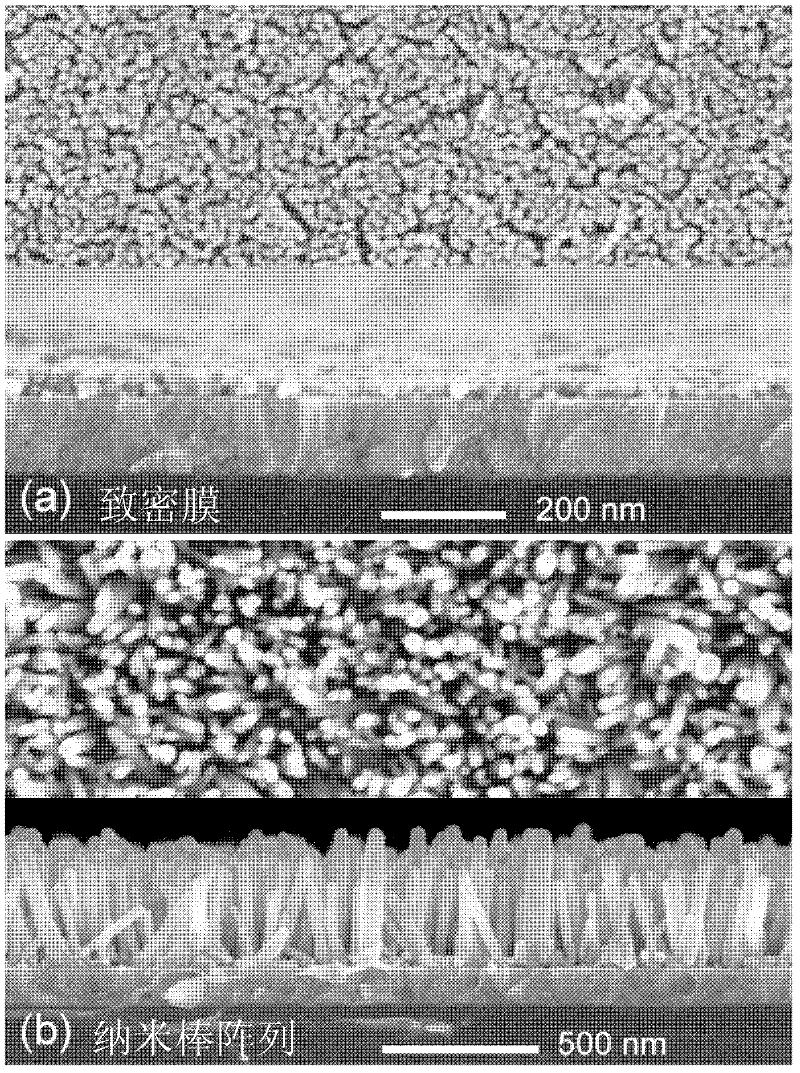

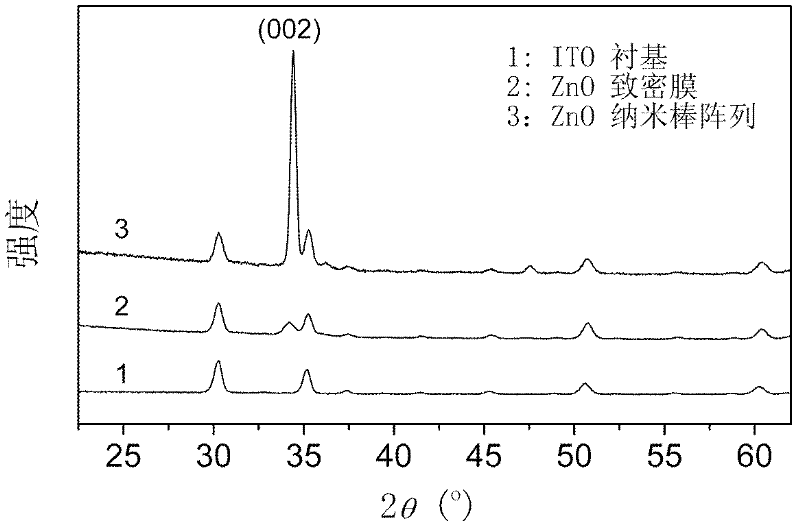

[0035] Example 1: Preparation of ZnO nanorod arrays.

[0036] (1-1) Preparation of ZnO dense film:

[0037] First, etch the ITO on the ITO conductive glass (ITO thickness is 100-120nm, ≤15Ω / □) to 12×4mm with concentrated hydrochloric acid and Zn powder 2 Thin strips; ultrasonically cleaned with acetone, isopropanol, and ultrapure water, and dried with dry nitrogen before use.

[0038] 0.16 g of zinc acetate [Zn(CH 3 COO) 2 2H 2 O] was dissolved in 1 g of water, and after complete dissolution, 4 ml of absolute ethanol was added, and then 100 μl of glacial acetic acid was added dropwise; the mixture was stirred at room temperature for 2 hours to obtain a colorless, clear and transparent solution. The above solution was spin-coated on ITO glass (2000 rpm, 60 seconds), and repeated four times to obtain a uniform film. Then, the zinc acetate film was aged in a container with a relative humidity of 52% (at room temperature) for 24 hours, and then calcined in a muffle furnace at...

Embodiment 2

[0043] Example 2: Preparation of ZnO-CdS heterogeneous core-shell nanorod arrays.

[0044] (2-1) Preparation of ZnO nanorod array: Same as Example 1.

[0045] (2-2) Preparation of ZnO-CdS heterogeneous core-shell nanorod arrays:

[0046] At room temperature, ZnO nanorod arrays were prepared at a concentration of 10 × 10 -3 mol / L of Cd(NO 3 ) 2 After soaking in the aqueous solution for 30 seconds, rinse with water for 30 seconds to remove a large amount of Cd(NO 3 ) 2 solution; then, this ZnO nanorod array was immediately placed in a 10×10 -3 mol / L Na 2 Soak in S aqueous solution for 30 seconds, and rinse with water for 30 seconds to remove unreacted Na 2 S solution; a SILAR process has been completed so far. The thickness of the CdS layer is controlled by the number (n) of SILAR processes. After repeating the SILAR process for n=30 and 50 times, a ZnO-CdS heterogeneous core-shell structure nanorod array (ie, ZnO-CdS-NA) was obtained.

[0047] (2-3) Characterization o...

Embodiment 3

[0049] Example 3: Preparation of polymer / heterogeneous core-shell nanorod array solar cells.

[0050] (3-1) Preparation of ZnO nanorod array: Same as Example 1.

[0051] (3-2) Preparation of ZnO-CdS heterogeneous core-shell structure nanorod array: same as Example 2.

[0052] (3-3) Preparation of MEH-PPV / ZnO-CdS-NA solar cells:

[0053] Using freshly distilled chlorobenzene as a solvent, prepare a MEH-PPV solution with a concentration of 10 mg / mL and stir it at room temperature for 24 hours. 100 microliters of MEH-PPV solution was uniformly dispersed on the ZnO-CdS-NA (n=30 or 50) layer, and then spin-coated (1500 rpm, 60 seconds) to deposit the polymer onto the ZnO-CdS-NA Above; after vacuum drying at 60°C for 12 hours to remove the solvent chlorobenzene, heat treatment at 150°C for 15 minutes in a nitrogen-protected glove box to allow the polymer to fully penetrate between the nanorods, and the polymer layer above the nanorods The thickness is 30-80nm.

[0054] Then, on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com