Knife blade rotary grass cutter of rotary grass cutter

A lawn mower and rotary technology, which is applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of howling and other problems, and achieve the effects of low cost, noise reduction and uniform grass clippings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further described below in conjunction with accompanying drawing and embodiment:

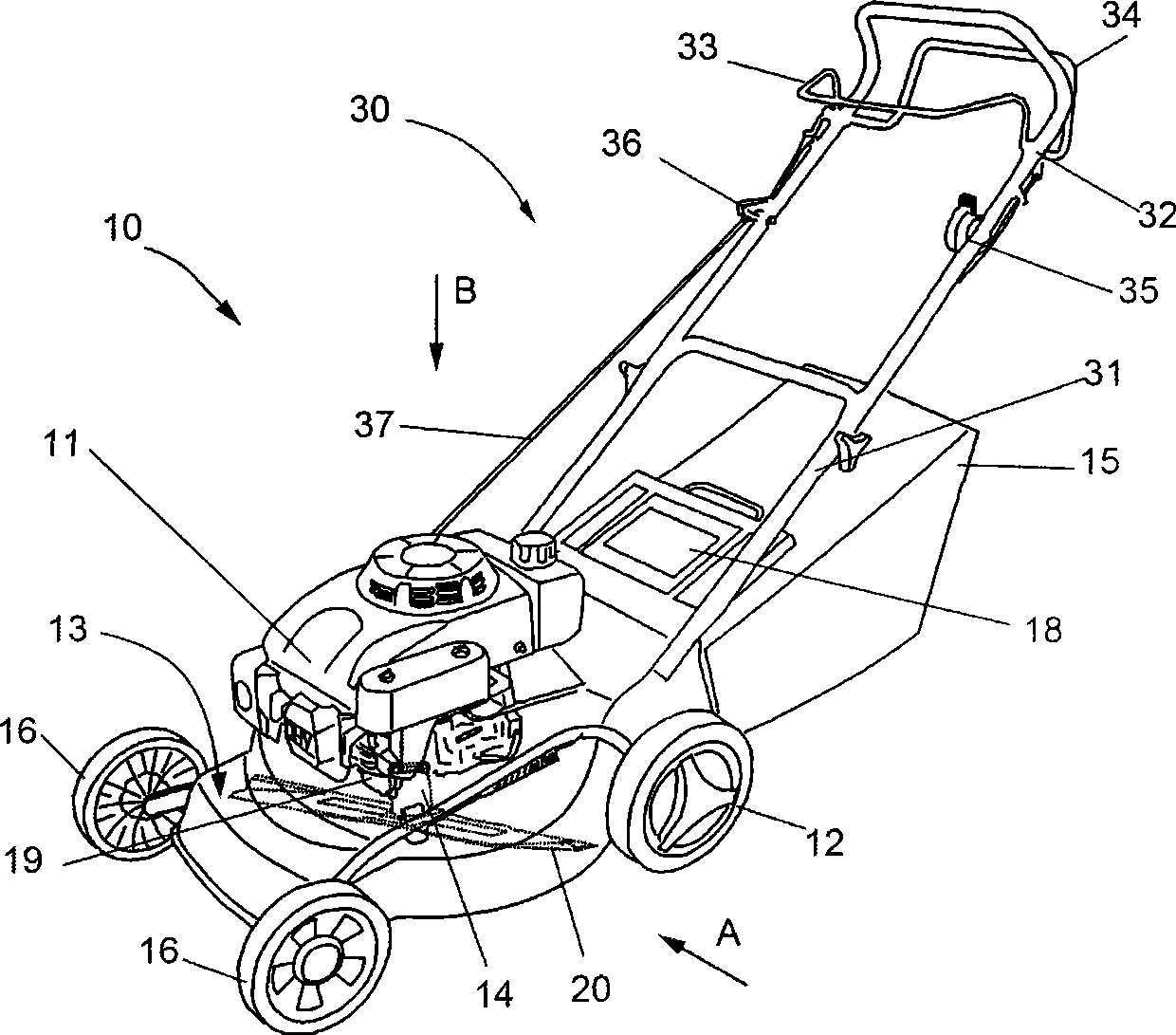

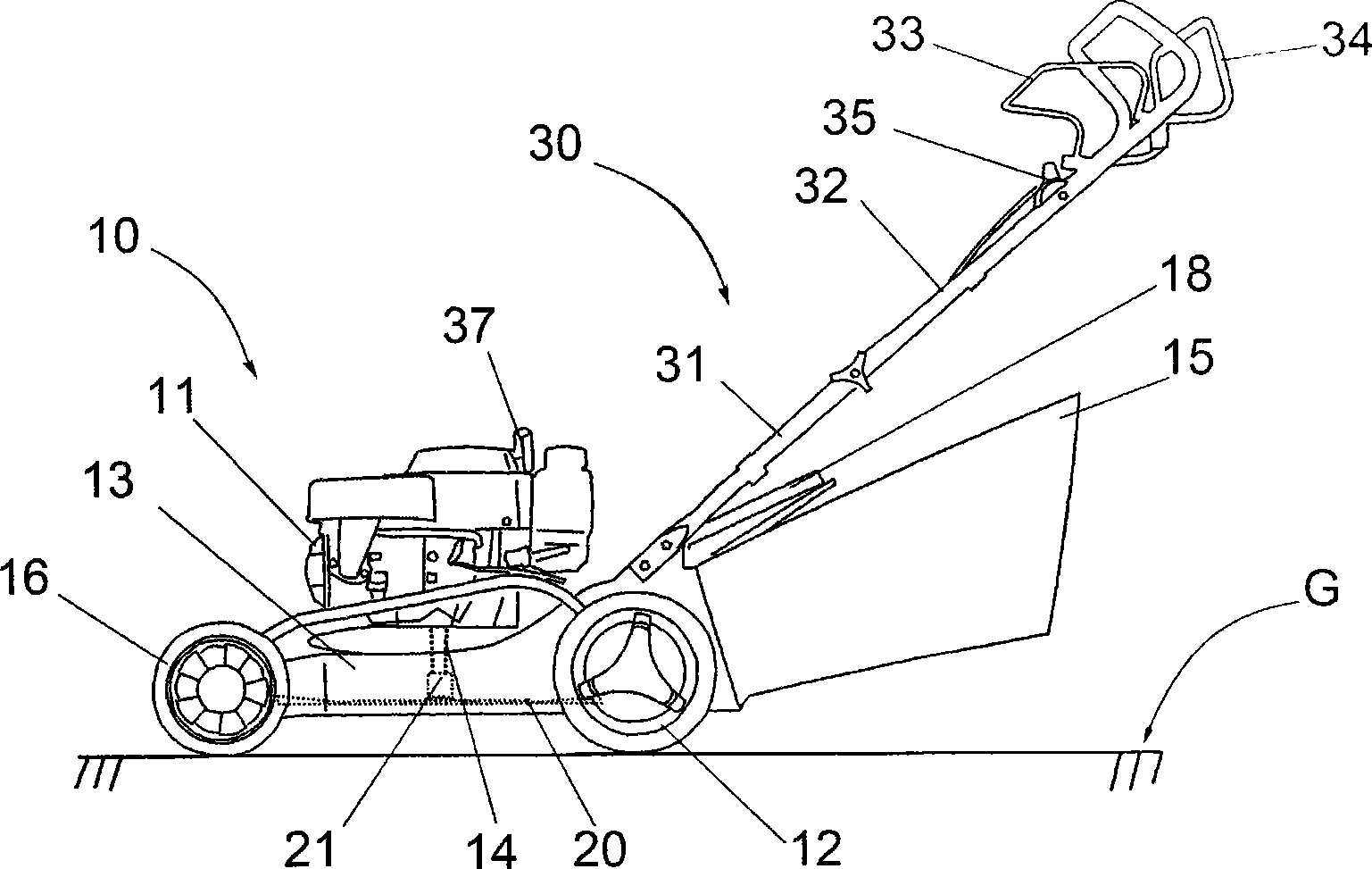

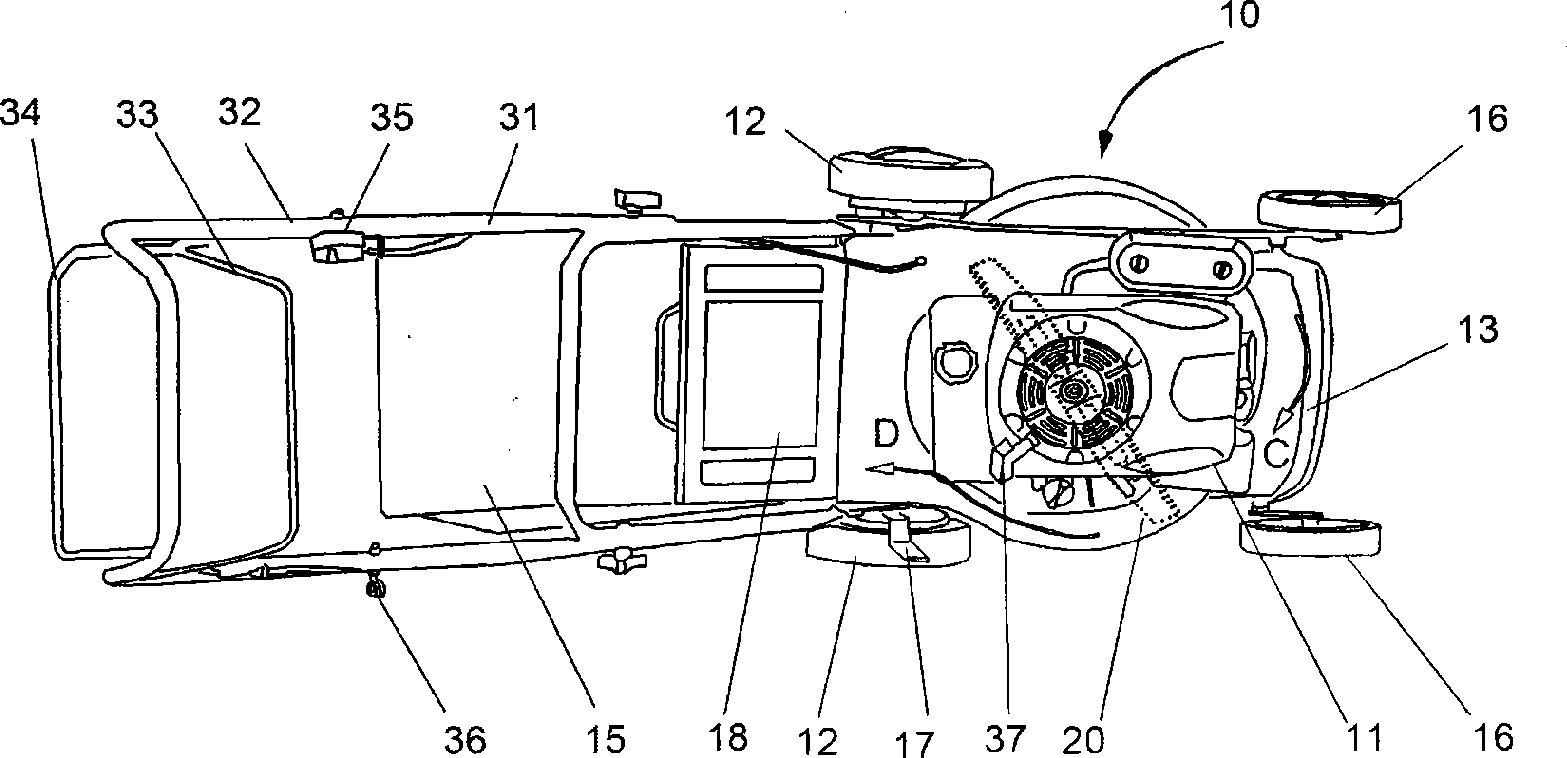

[0020] First, refer to figure 1 , figure 2 and image 3 , shown in the figure is the lawn mower using the blade of the present invention. The lawn mower 10 shown in this example is a self-propelled lawn mower equipped with an engine 11 capable of turning the blade 20 and driving the two rear wheels 12 . The engine 11 is installed on the base assembly 13, and the blade 20 is fixed on the output shaft 14 of the engine 11, and the torque is transmitted to the output shaft 14 by the engine 11 to rotate the blade 20, so as to complete the mowing operation and cut the grass Grass clippings are discharged into the grass collector 15.

[0021] Two front wheels 16 are installed on the base assembly 13, and two front wheels 16 and two rear wheels 12 are installed on the base assembly 13 of the lawn mower 10 to adjust the adjustment height of the lawn mower 10 by the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com