Forming mold and method of planar ceramic target material

A technology for ceramic targets and forming molds, which is applied in ceramic forming machines, molds, mold auxiliary parts, etc., can solve the problems of difficulty in obtaining compactness, low green strength, and high price, and achieves reduction of hydraulic press molding and one-time molding. The effect of handling process, improving yield and material yield, and reducing the risk of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

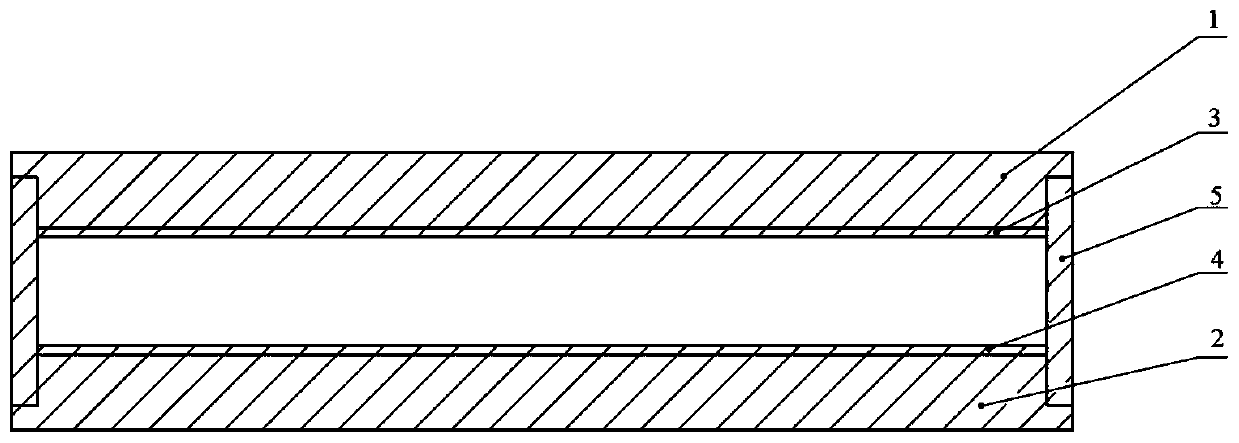

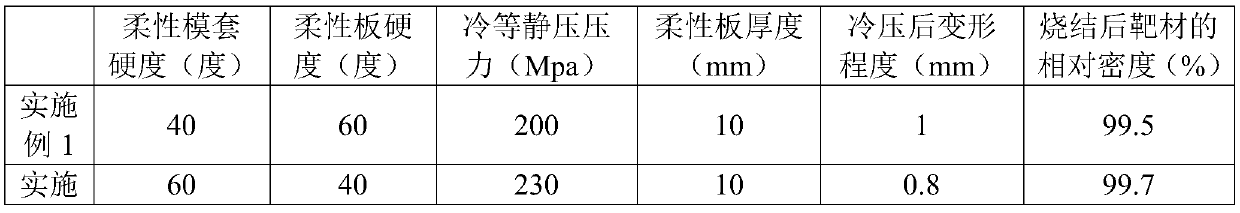

[0029] A molding die for a planar ceramic target, such as figure 1 As shown, it includes a steel mold, a flexible mold cover and a flexible plate. The steel mold includes an upper steel cover 1 and a lower steel cover 2. The upper steel cover 1 and the lower steel cover 2 are installed and combined to form a cavity body. The upper steel cover 1 and the lower steel cover 2 The material of the lower steel cover 2 is 45# steel, the two ends of the steel mold are provided with grooves, the flexible mold sleeve is installed in the groove, and is sealed with the steel mold, and the flexible plate is made of upper rubber The plate 3 and the lower rubber plate 4 are combined to form a hollow body placed in the steel mold. The cavity formed between the upper rubber plate 3, the lower rubber plate 4 and the flexible mold cover 5 is a powder filling cavity 6, and the powder filling cavity 6 is a square cavity; the material of the flexible mold cover 5 is polyurethane, and the Shore hardn...

Embodiment 2

[0037] A molding die for a planar ceramic target, such as figure 1 As shown, it includes a steel mold, a flexible mold cover and a flexible plate. The steel mold includes an upper steel cover 1 and a lower steel cover 2. The upper steel cover 1 and the lower steel cover 2 are installed and combined to form a cavity body. The upper steel cover 1 and the lower steel cover 2 The material of the lower steel cover 2 is 304 stainless steel. Both ends of the steel mold are provided with grooves. The flexible mold sleeve is installed in the groove and is sealed with the steel mold. The flexible plate is made of upper rubber The plate 3 and the lower rubber plate 4 are combined and placed in the cavity in the steel mold. The cavity formed between the upper rubber plate 3, the lower rubber plate 4 and the flexible mold cover 5 is a powder filling cavity 6, and the powder filling cavity 6 is a square cavity; the material of the flexible mold cover 5 is polyurethane, the Shore hardness is...

Embodiment 3

[0045] A molding die for a planar ceramic target, such as figure 1 As shown, it includes a steel mold, a flexible mold cover and a flexible plate. The steel mold includes an upper steel cover 1 and a lower steel cover 2. The upper steel cover 1 and the lower steel cover 2 are installed and combined to form a cavity body. The upper steel cover 1 and the lower steel cover 2 The material of the lower steel cover 2 is 45# steel, the two ends of the steel mold are provided with grooves, the flexible mold sleeve is installed in the groove, and is sealed with the steel mold, and the flexible plate is formed by the upper The rubber plate 3 and the lower rubber plate 4 are combined and placed in the cavity in the steel mold. The cavity formed between the upper rubber plate 3, the lower rubber plate 4 and the flexible mold sleeve 5 is a powder filling cavity 6, and the powder filling The cavity 6 is a square cavity; the material of the flexible mold cover 5 is polyurethane, and the Shore ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com