Omnidirectional filtering device for washing machine

A filter device, washing machine technology, applied in washing devices, other washing machines, applications, etc., can solve problems such as failure to achieve all-round filtration, and achieve the effects of low production cost, favorable for popularization and use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

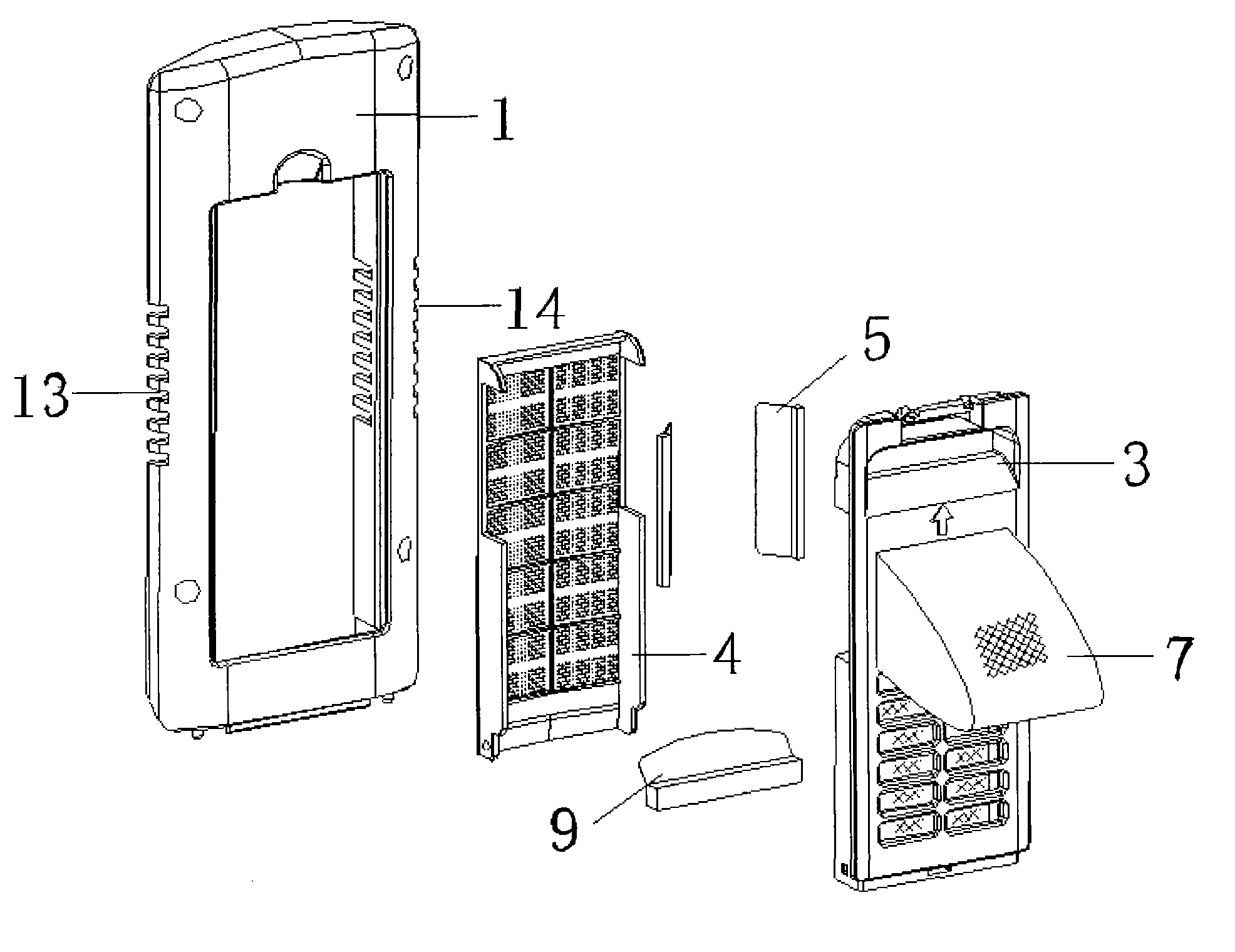

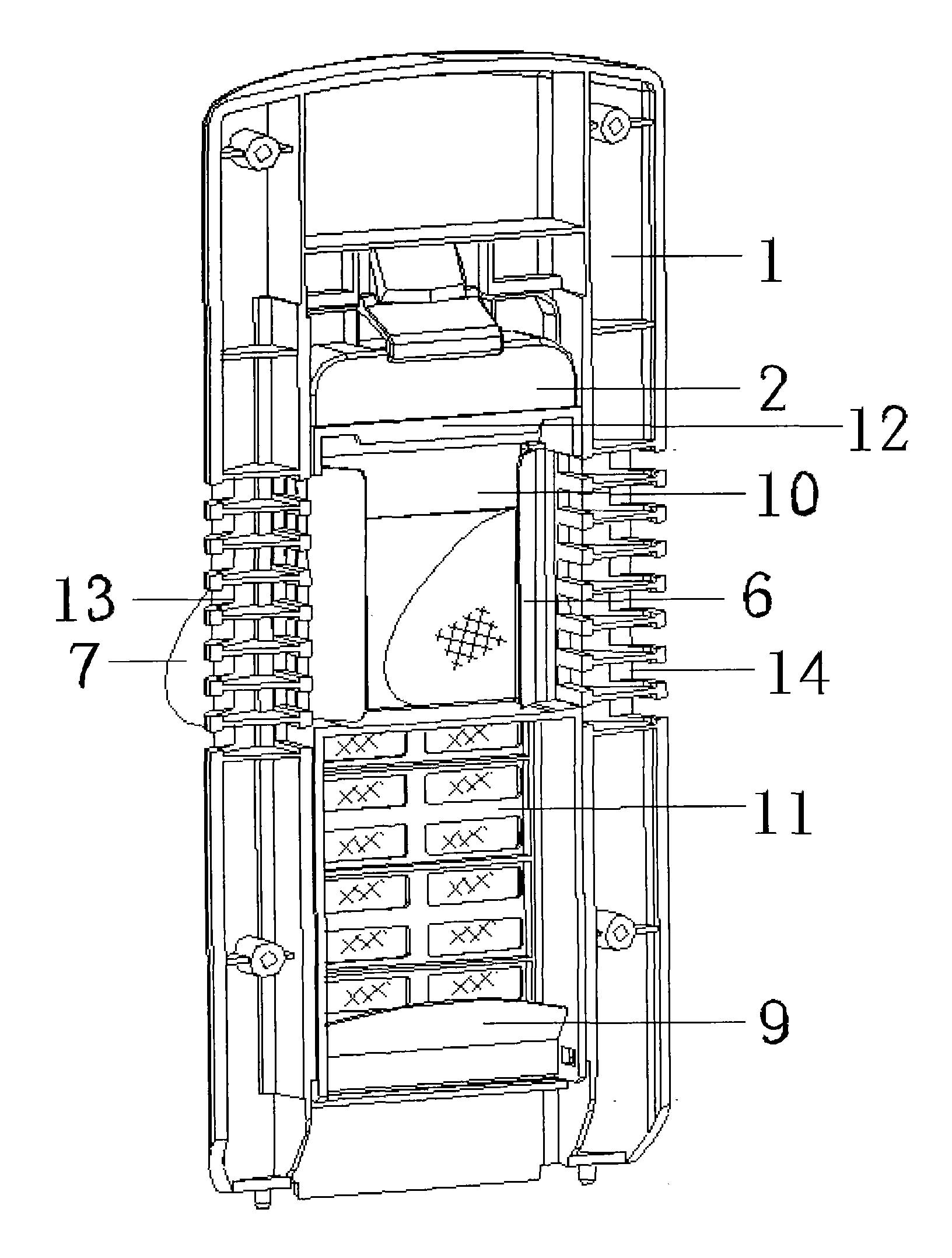

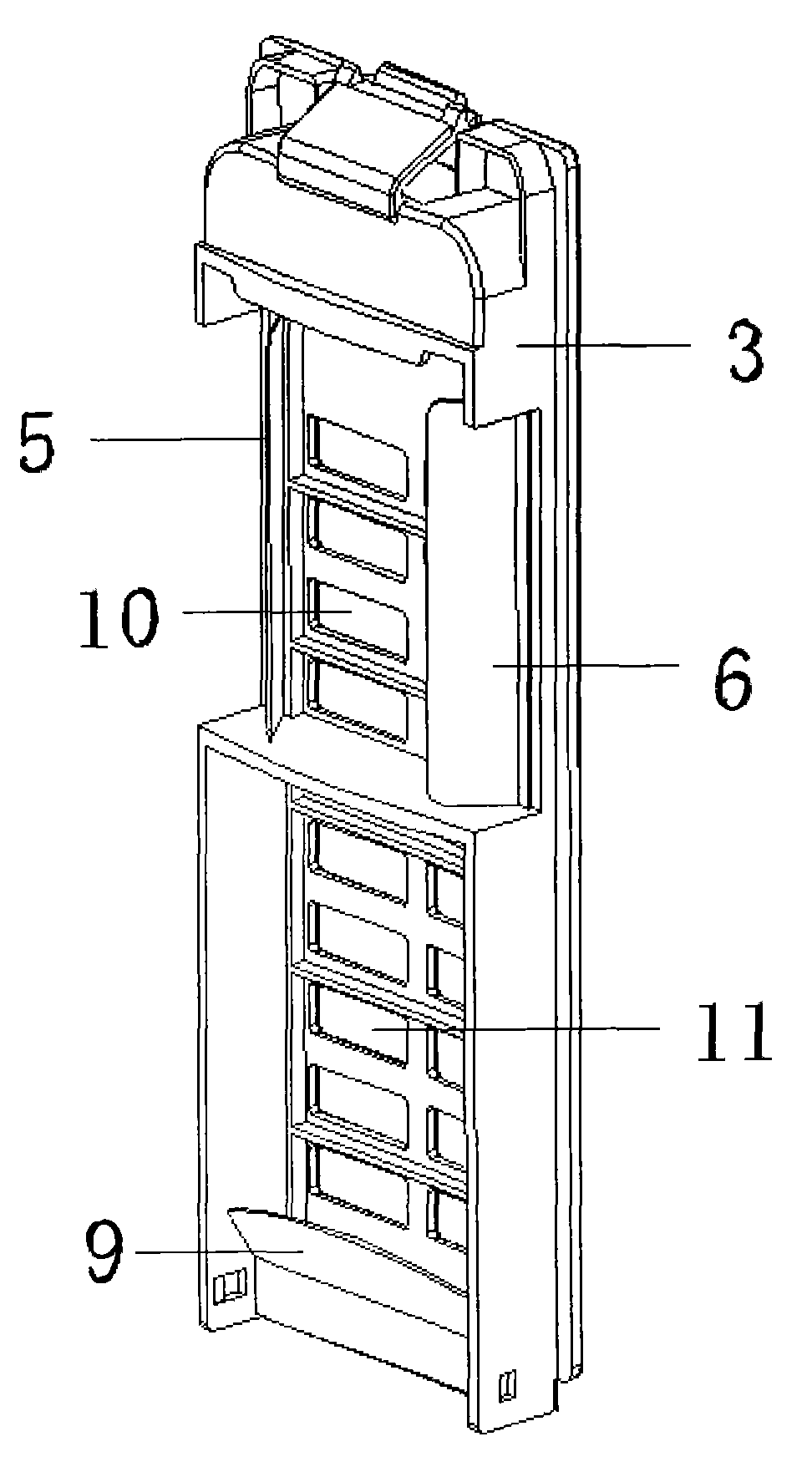

[0039] Such as figure 1 ,2 As shown, the all-round filter device for washing machine of the present invention includes a filter cover 1 and a lint filter 2 embedded in the filter cover 1, the lint filter 2 includes a box-type front cover 3 and a rear cover 4, and the middle part of the front cover 3 is provided with a The horizontal rib divides the filter cavity of the lint filter into an upper filter cavity 10 and a lower filter cavity 11, and the left and right side walls of the upper filter cavity 10 and the bottom of the lower filter cavity 11 are provided with a water inlet of the filter device. Wherein the upper filter cavity 10 is used to collect the lint that enters the water through its left and right side walls, and the lower filter cavity 11 is used to collect the lint that enters the water from the bottom. Therefore, the present invention can not only effectively filter the washing water that enters the water inlet at the bottom of the lint filter from the bottom o...

Embodiment 2

[0044] Such as figure 1 , 2 As shown, the all-round filter device for washing machine of the present invention includes a filter cover 1 and a lint filter 2 embedded in the filter cover 1, the lint filter 2 includes a box-type front cover 3 and a rear cover 4, and the middle part of the front cover 3 is provided with a The transverse rib divides the filter cavity of the lint filter into an upper filter cavity 10 and a lower filter cavity 11, and the vertical height ratio of the upper filter cavity 10 and the lower filter cavity 11 along the washing tub is 1:5. The left and right side walls of the upper filter chamber 10 and the bottom of the lower filter chamber 11 are provided with water inlets of the filter device. Wherein the upper filter cavity 10 is used to collect the lint that enters the water through its left and right side walls, and the lower filter cavity 11 is used to collect the lint that enters the water from the bottom. Therefore, the present invention can not...

Embodiment 3

[0049] Compared with Embodiment 1, the difference is that the washing machine filter device also includes a filter cover (not shown in the figure) located on the filter front cover 3, and the filter cover fixes the bag filter 7 to the filter cover Between the front cover 3 of the lint filter. The sheet-type filter plate is separated into a window type. The longitudinal height ratio of the upper filter cavity 10 and the lower filter cavity 11 along the washing tub is 1:6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com