Gas gun system for shooting hail

A gas cannon and hail technology, which is applied in the field of gas cannon system and hail launch gas cannon system, can solve the problems of inability to guarantee the integrity of hail, slow loading speed, and unsatisfactory continuous launch ability, so as to improve continuous launch capability, Improve the speed of reloading and maintain the effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

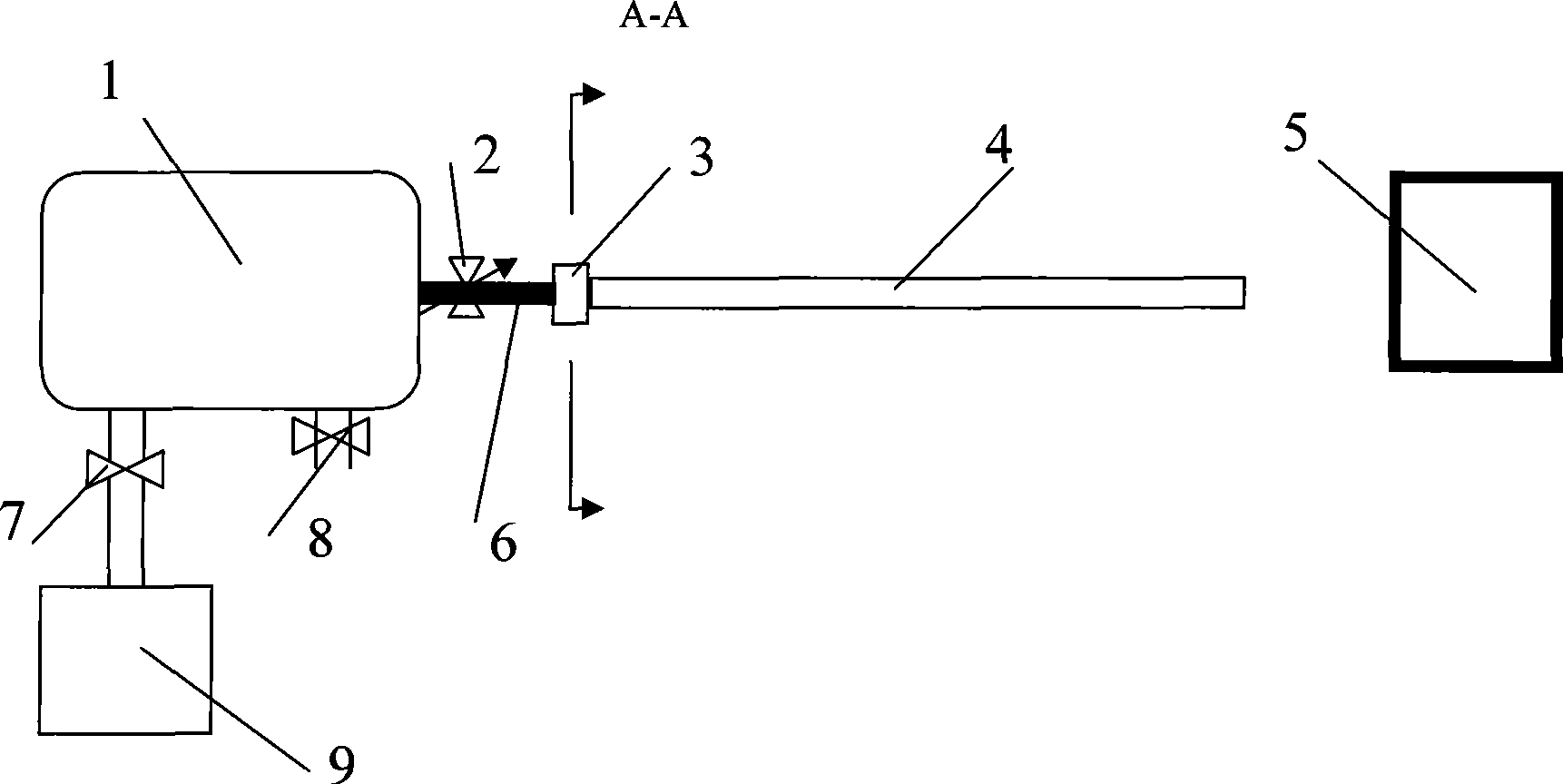

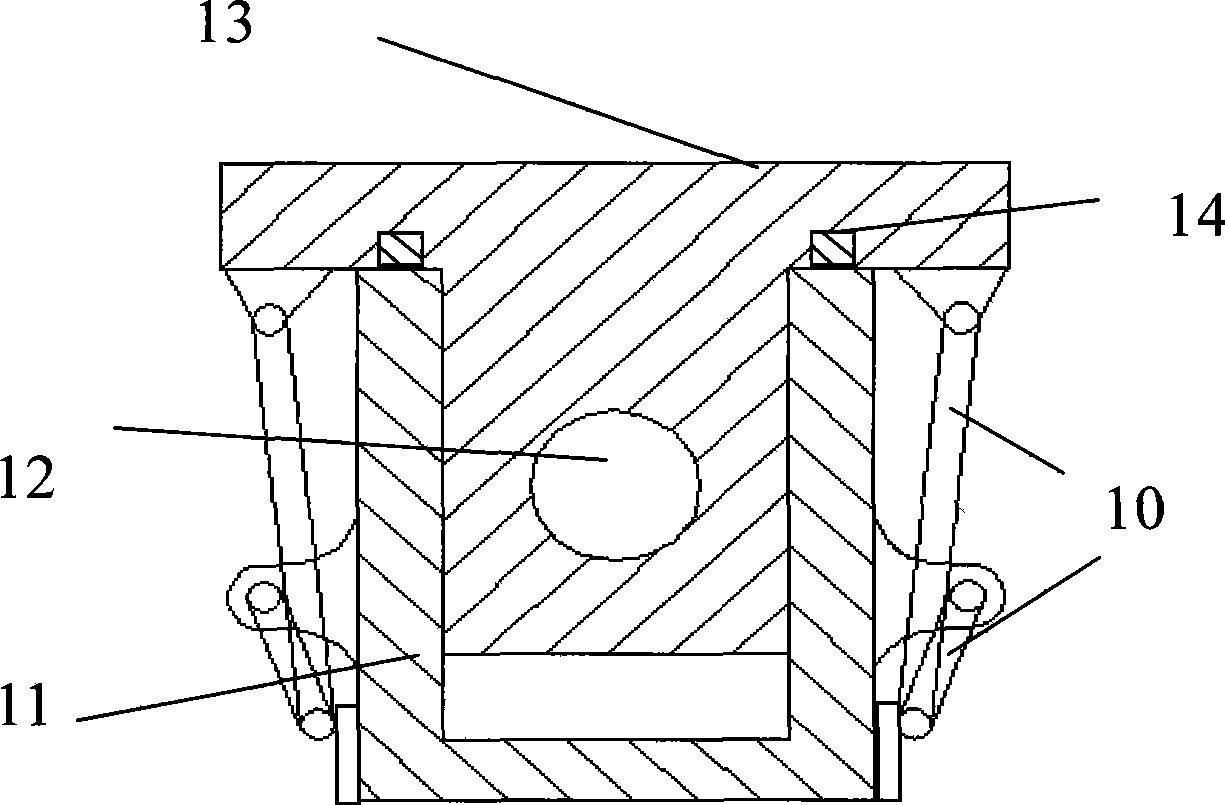

[0008] combine figure 1 and figure 2 As shown, a gas cannon system for launching hail, including: a high-pressure gas chamber 1, a quick control valve 2, a launch tube 4, a high-pressure gas pipe 6, an intake valve 7, a gas release valve 8 and a high-pressure air pump 9, wherein: a high-pressure air pump 9 The high-pressure air chamber 1 is connected with the high-pressure air chamber 1 through the intake valve 7, and the high-pressure air chamber 1 is also provided with a vent valve 8, and one end of the high-pressure air pipe 6 is connected with the high-pressure air chamber 1, and a quick control valve 2 is provided on the high-pressure air pipe 6 for Save high-pressure gas and maintain high-pressure gas pressure. The gas cannon system also includes a detachable quick-loading mechanism 3. The quick-loading mechanism 3 is connected to the other end of the high-pressure air pipe 6. The quick-loading mechanism 3 is composed of a locking link 10, The quick-loading mechanism b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com