Fluid supply method and apparatus

A technology of liquid and supply source, applied in the field of liquid supply system, can solve the problems of difficult printing head, restricting the installation of printing head, etc., and achieve the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

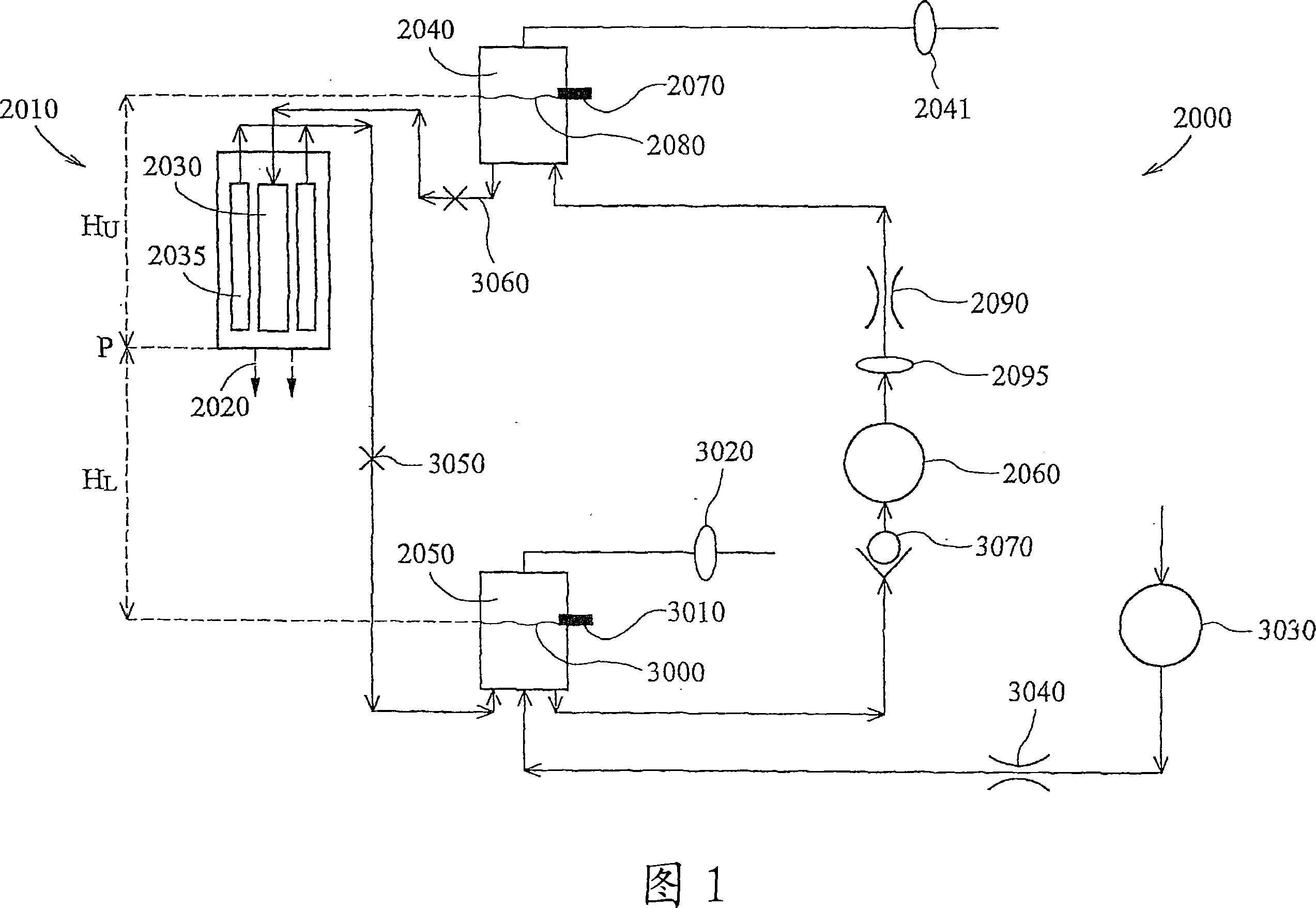

Embodiment Construction

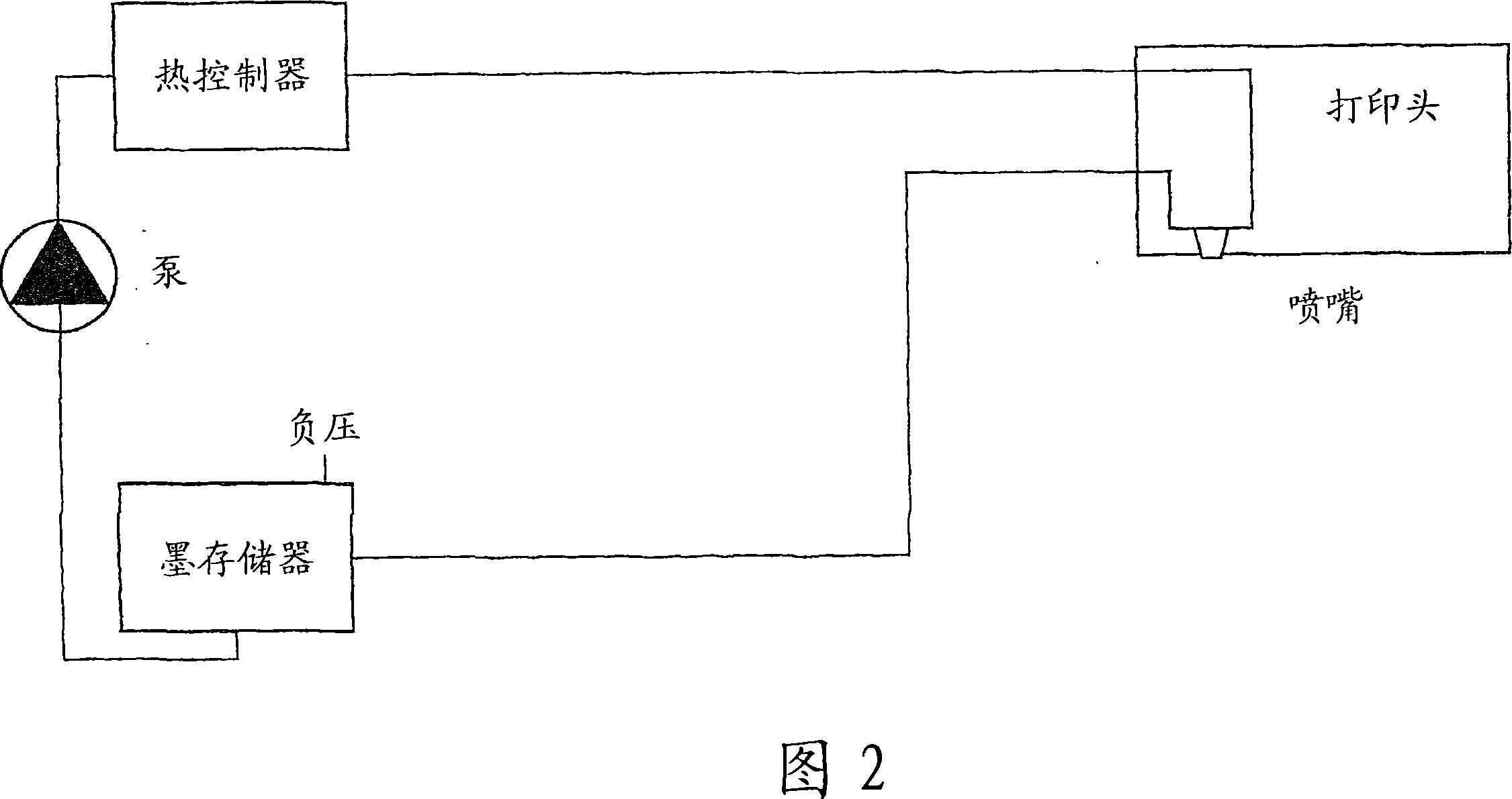

[0031] Figure 2 shows a closed, thermally controlled, recirculating-throgh-ejection chamber liquid supply system with negative pressure at the nozzle. The liquid supply system has the advantage of being completely isolated from the atmosphere (except at the nozzles) so that there is no problem of sucking in air. Moreover, the system is simple and thus low in cost. The system is also compact and flexible in terms of component arrangement, especially its height. The pump generates positive pressure upstream and negative pressure downstream, and the pump speed is selected to maintain flow in excess of the maximum printhead jet. The flow is typically 10 times the maximum jet rate and can be as high as 30 times the maximum jet rate.

[0032] The pumping circuit (pumping circuit) between the pump and the nozzle, including the internal flow path of the print head, is roughly symmetrical in its liquid resistance, but in order to generate the small negative pressure required at the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com