Novel making process method of lithium ion battery

A lithium-ion battery and manufacturing process technology, applied in electrolyte battery manufacturing, sustainable manufacturing/processing, non-aqueous electrolyte batteries, etc., can solve the problems of battery impact, corrosion appearance, shell expansion, etc., to reduce the dependence on the external environment , reduce cost input and ensure the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

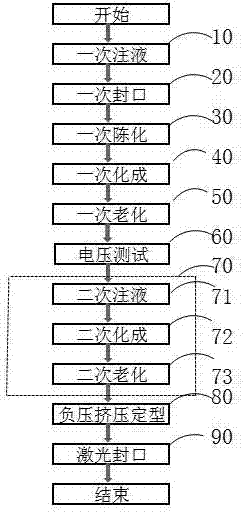

[0014] Below in conjunction with schematic diagram, the embodiment of the present invention is described in detail:

[0015] Please refer to figure 1 , the manufacturing process of the novel lithium-ion battery in the embodiment of the present invention comprises:

[0016] One-time liquid injection step 10: when the lithium-ion battery is liquid-filled, inject the preset ratio of the total weight of the electrolyte. For a liquid injection step 10, the total weight of the electrolyte is a predetermined weight of the electrolyte required to meet the performance of the battery cell. The battery performance includes capacity, cycle and rate performance, etc., and the preset ratio is 70%- 100%, the ambient humidity of this step is 1% to 2%, and the temperature is 20-25°C. In the first example of the present invention, the injected electrolyte can meet the performance requirements of the battery, and the battery does not need secondary liquid injection, that is, the three steps fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com