Device for realizing rotary fluid supply and recycle during revolving/rotating type magnetorheological polishing

A technology of magnetorheological polishing and orbital rotation, which is applied in the direction of grinding/polishing equipment, metal processing equipment, manufacturing tools, etc. It can solve the problems of easy deposition and unsmooth operation, reduce workload, facilitate maintenance, and avoid deposition and the effect of not running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

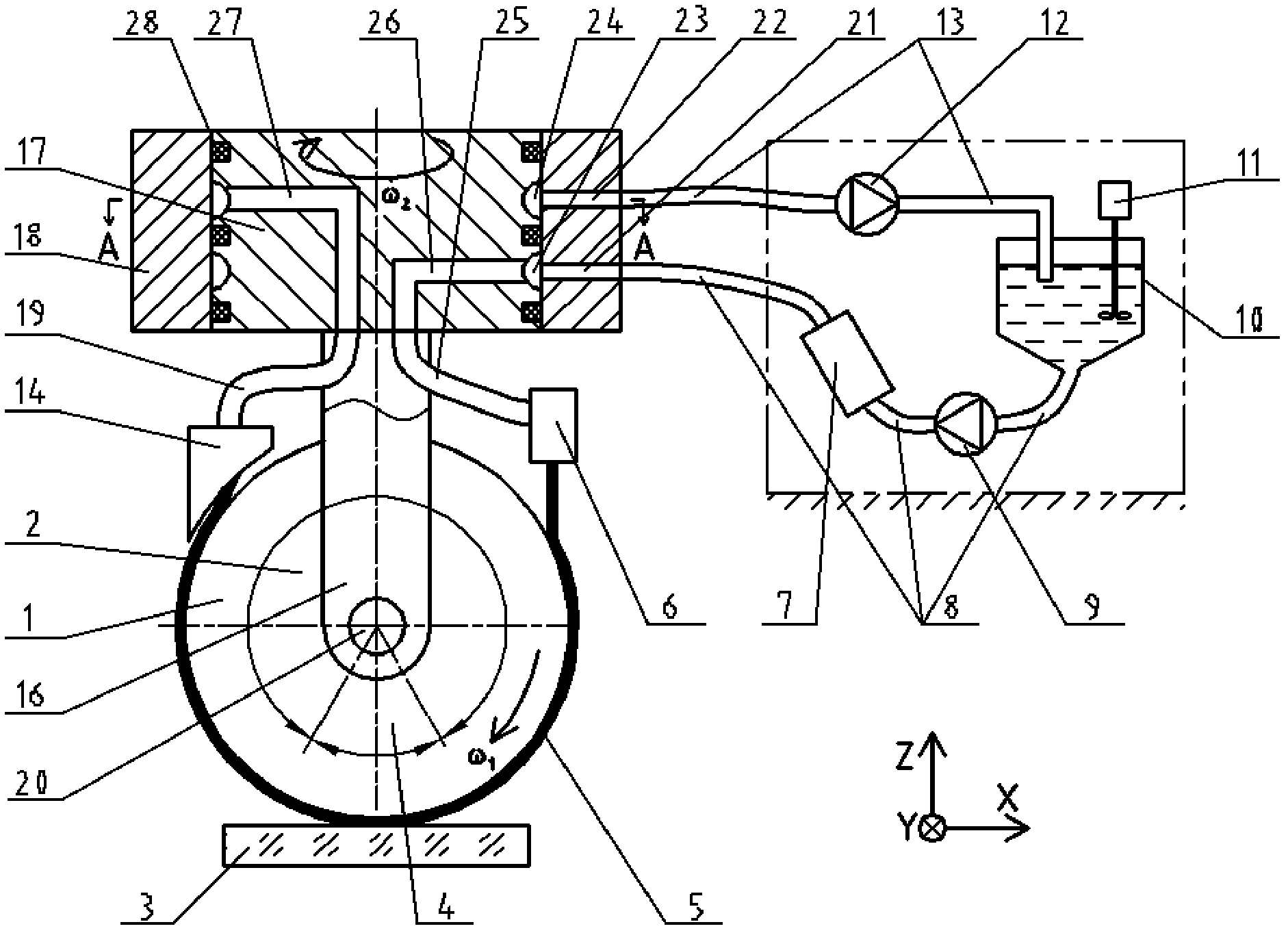

[0020] The principle, structure and working process of the present invention will be further described below in conjunction with the accompanying drawings.

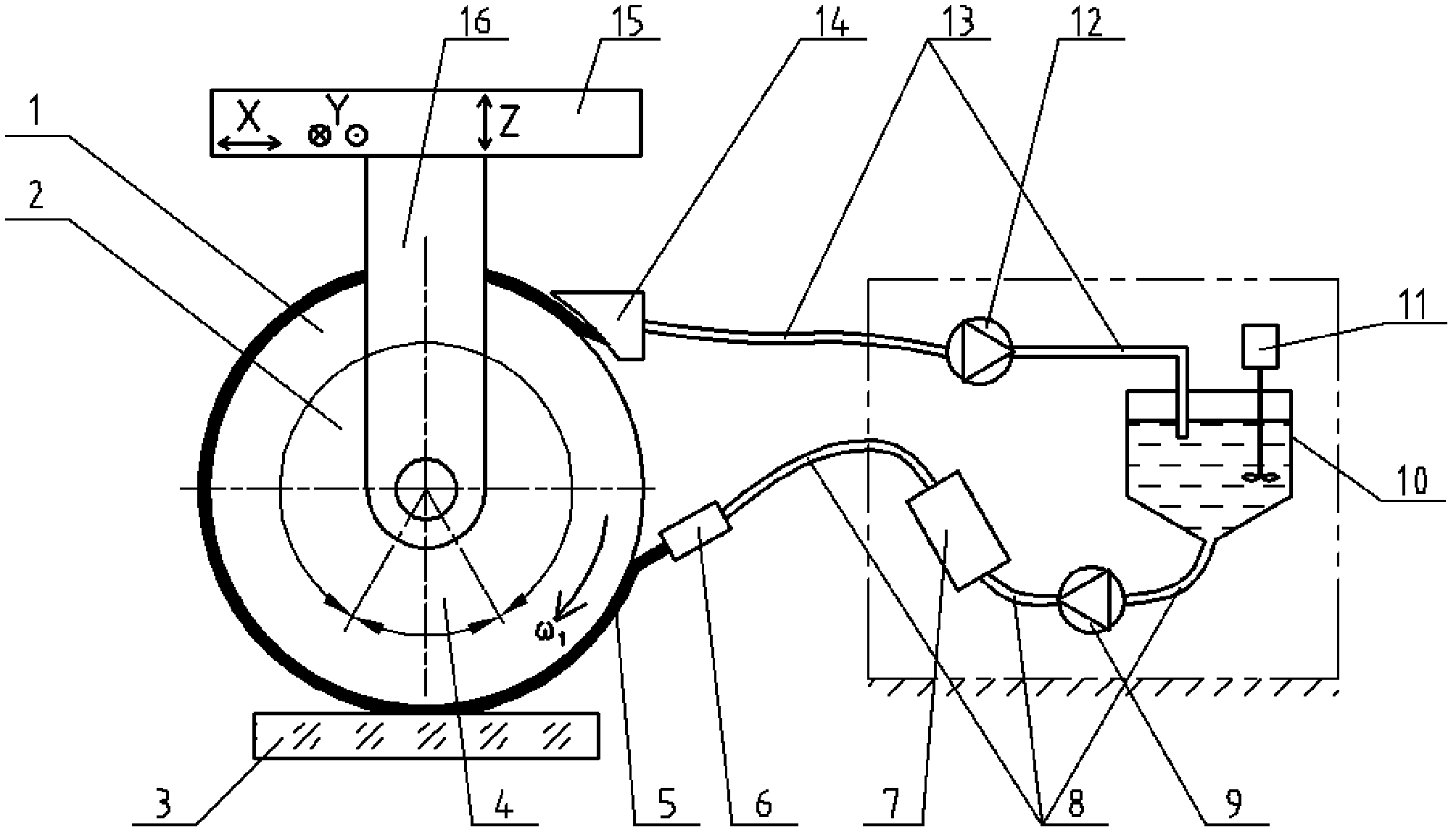

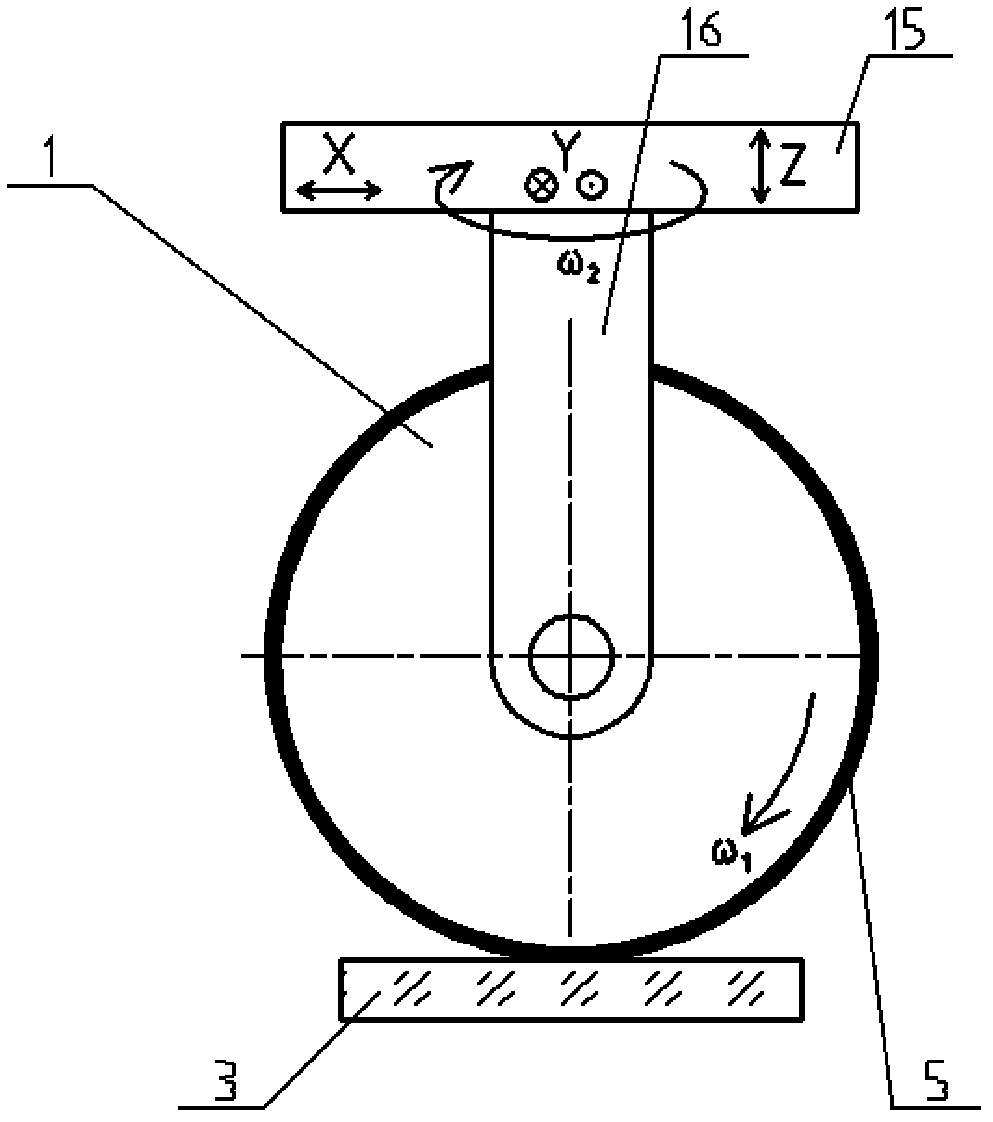

[0021] image 3 A schematic diagram of the principle structure of a device for realizing rotary liquid supply and recovery in the revolving magnetorheological polishing provided by the present invention, the device includes a housing 18, a revolving base 17, a bearing seat 16, a rotating shaft 20, a polishing wheel 1 and Circulatory system; the revolving base 17 is installed inside the casing 18 and performs revolving motion along the Z-axis direction; the bearing seat 16 is fixed on the revolving base 17; the rotation shaft 20 is installed on the bearing seat 16 through a bearing above; the polishing wheel 1 is fixed on the rotation shaft 20; the circulation system includes a liquid storage tank 10, an agitator 11 arranged in the liquid storage tank 10, a liquid injection pipe 8, a liquid suction pipe 13, a liquid inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com