Watches and method for their production

A technology of bamboo and bamboo nails, applied in the direction of nails, U-shaped nails, connecting components, etc., can solve the problems of insufficient strength, difficulty in nailing high-density wood, and uncontrollable depth of wood penetration, etc., to achieve high density and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

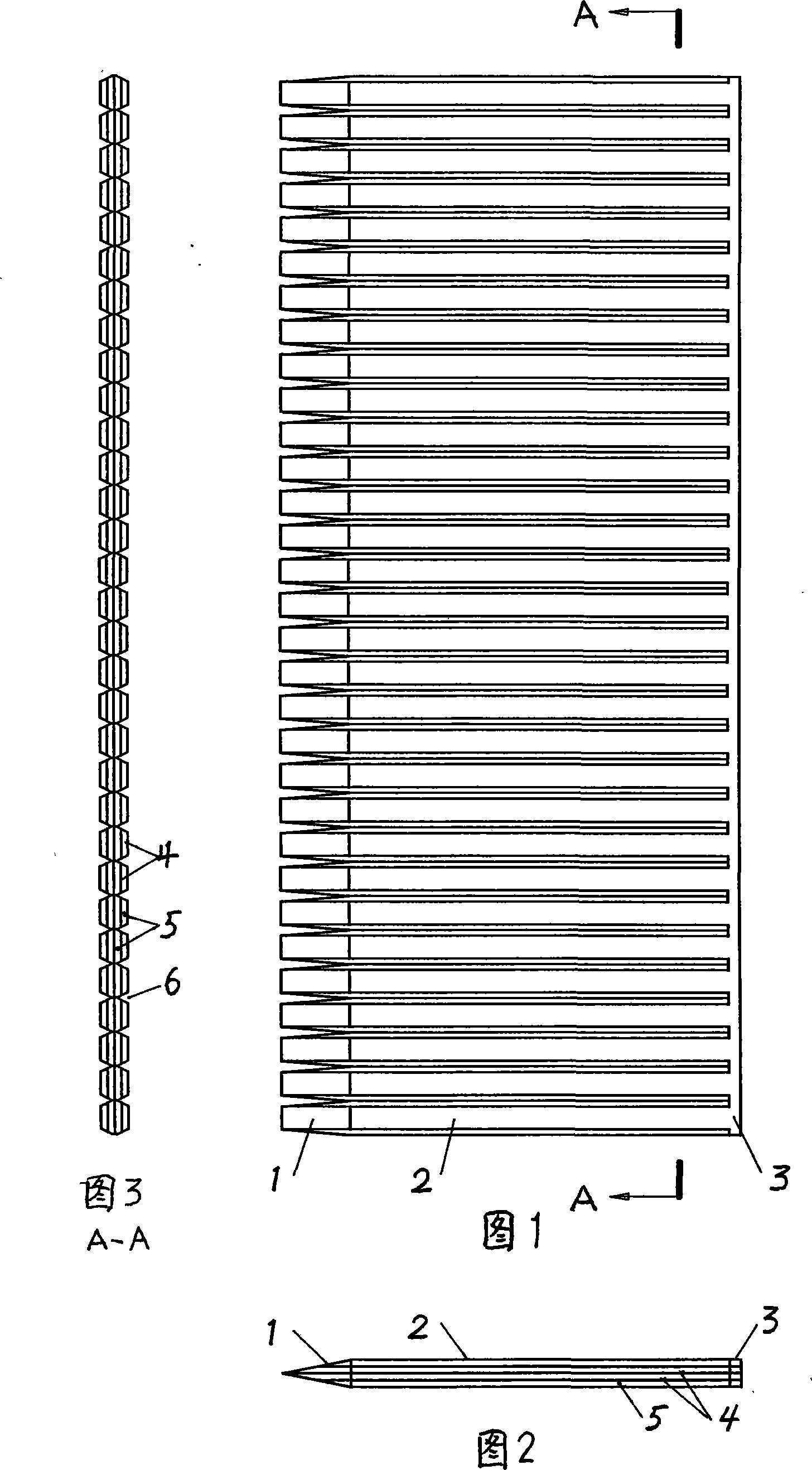

[0019] The present invention is described in detail below in conjunction with embodiment and with reference to accompanying drawing, manufactures this row nail and carries out as follows:

[0020] (1) Select large-scale bamboos such as moso bamboo, hemp bamboo, giant dragon bamboo and other 4-5-year-old bamboos with a breast diameter greater than 10cm, remove bamboo green and bamboo yellow, and use bamboo meat to spin into veneers or split strips into thin slices, and make the same bamboo section slices together.

[0021] (2) Drying: Send the flakes into a drying kiln to dry to a moisture content of 4%-10%.

[0022] (3) Sizing by dipping or double-sided gluing, it is better to use phenolic glue with high hardness after curing. Dipping for 10-180 seconds, the amount of glue applied on both sides is 150-240g / m 2 , The solid content of the glue is 15-50%. The length of dipping time is directly proportional to the thickness of bamboo slices.

[0023] (4) Re-dry until the moist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com