Environment-friendly fiber framework material dip solution and dipping process

An environment-friendly, fiber-skeleton technology, applied in the field of environment-friendly fiber-skeleton material dipping solution and dipping process, can solve pollution and other problems, and achieve good bonding effect and low stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 9-15

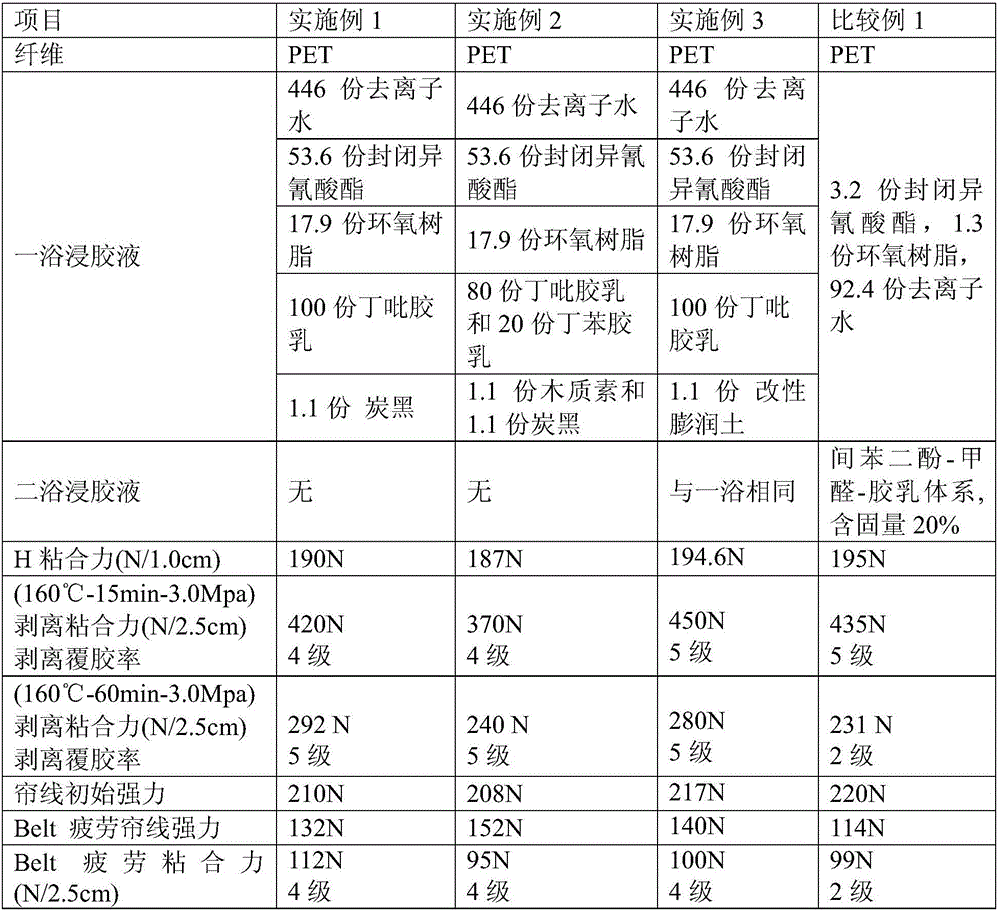

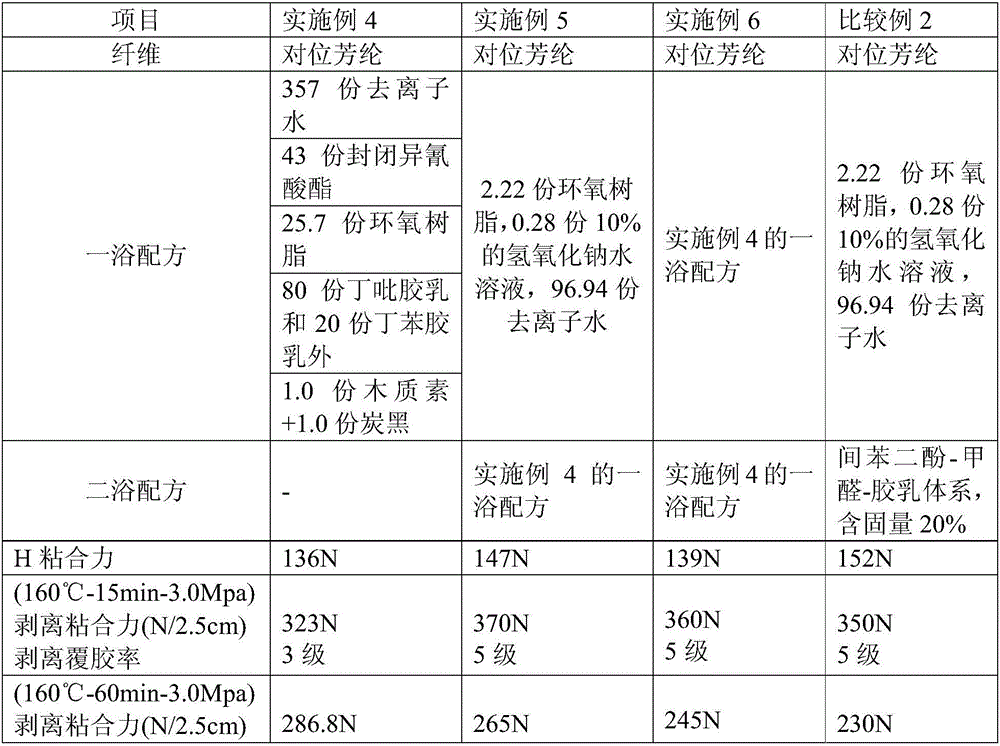

[0039] Examples 9-15 were tested, test method: H adhesion was tested according to GB / T 19390-2014 method, peeling surface adhesion was measured and rated according to ASTM-D4393 method, the results are shown in Table 4.

[0040] Table 4

[0041]

[0042]

[0043] It can be seen from Table 4 that the results of Example 10 show that the one-bath dipping process is not easy to use if the solid content is below 10%, otherwise the adhesive performance will be adversely affected. Examples 11 and 12 show that below 5% solids, even with double-bath immersion, the adhesive properties will be adversely affected. Example 13 shows that when the total solid content is more than 10%, reducing the rubber latex consumption to 80 parts, H extraction adhesion has adverse effects. Example 14 shows that when the solid content is more than 10%, the rubber latex consumption is 80 parts, the rubber modifier consumption is 0.5 part, and the carboxylated styrene-butadiene latex with higher acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com