Low-smoke halogen-free flame-retardant gum-dipped elastic cloth and preparation method thereof

A technology of elastic cloth and rubber dipping, which is applied in the preparation of low-smoke, halogen-free, flame-retardant, dipped elastic cloth, and in the field of low-smoke, non-halogen, flame-retardant, dipped elastic cloth, which can solve the problem of weak resistance to external force, oxygen barrier and sealing Problems such as loss of characteristics, generation of pores, etc., to achieve the effect of not being easy to break, not demanding equipment requirements, and ensuring full performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

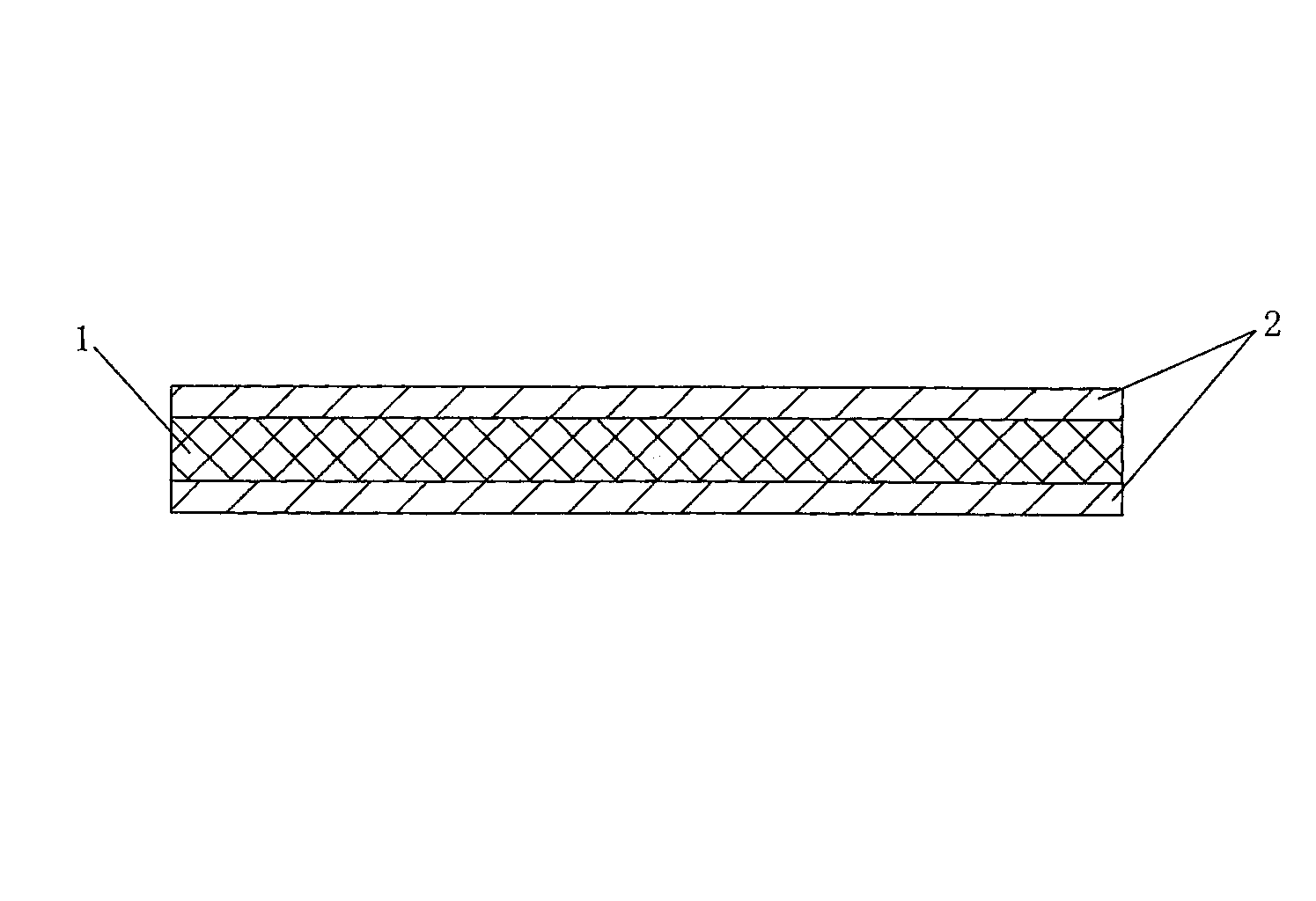

[0025] please see figure 1 , this example is based on the preparation figure 1 The low-smoke, halogen-free, flame-retardant dipped elastic cloth with the structure shown is taken as an example.

[0026] ) to prepare the dipping solution, first introduce 20 g of polyethylene glycol, 10 g of polyurethane, 300 g of dimethyl sulfoxide and 10 mg of polysiloxane emulsion with a concentration of 30% by weight, which are weighed in parts by weight. Stir in the reaction kettle of the stirrer at a heating temperature of 90°C and a stirring speed of 500n / min for 120min. After cooling, add an inorganic flame retardant, Al(OH), weighed by weight. 3 100g, Mg(OH) 2 40g and SiO 2 20g and then stirred for 30min evenly, the rotating speed of the stirrer was 1500n / min, to obtain the dipping solution;

[0027] B) Dipping, first introduce the dipping liquid obtained in step A) from the reaction kettle into the dipping tank, and then use the weft plain glass fiber cloth obta...

Embodiment 2

[0029] A) To prepare the dipping solution, first introduce 10g of polyethylene glycol, 10g of polyurethane, 100g of dimethyl sulfoxide and 2mg of polysiloxane emulsion with a concentration of 30% by mass, which are weighed in parts by weight. Stir in a reactor with a stirrer at a heating temperature of 100°C and a stirring speed of 800n / min for 180min. After cooling, add an inorganic flame retardant, Al(OH), weighed by weight. 3 80g was further stirred for 60min evenly, and the rotating speed of the stirrer was 1000n / min to obtain the dipping solution;

[0030] B) Dipping, first introduce the dipping liquid obtained in step A) from the reaction kettle into the dipping tank, and then use the polyester nonwoven fabric obtained from high-strength flame-retardant polyester fiber as raw material and spunlace method as the flame-retardant fiber base cloth 1. Pass through the dipping liquid in the dipping tank at a speed of 20m / min, and pass between the paired coating rollers ...

Embodiment 3

[0032] A) To prepare the dipping solution, first introduce 40g of polyethylene glycol, 60g of polyurethane, 500g of dimethylformamide and 20mg of polysiloxane emulsion with a concentration of 30% by mass, which are weighed in parts by weight. Stir in a reactor with a stirrer at a heating temperature of 80°C and a stirring speed of 200n / min for 300min. After cooling, add an inorganic flame retardant, Al(OH), weighed by weight. 3 100g, Mg(OH) 2 100g, CaCO 3 50g and SiO 2 50g was further stirred for 45min evenly, and the rotating speed of the stirrer was 2000n / min to obtain the dipping solution;

[0033] B) Dipping, first introduce the dipping liquid obtained in step A) from the reaction kettle into the dipping tank, and then use the high-strength flame-retardant nylon fiber as raw material and the weft-plain nylon fabric obtained by weaving knitting and weft-knitting technology as flame-retardant The fiber base cloth 1 passes through the dipping solution in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Smoke density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com