Method for preparing molding material for chemical delivery pipes

A technology for molding materials and drug delivery tubes, which is applied in the field of preparation of drug delivery tube molding materials, can solve the problems of insufficient sewage purification and bacterial treatment, and achieve the effects of convenient dosing, meeting the needs of use, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

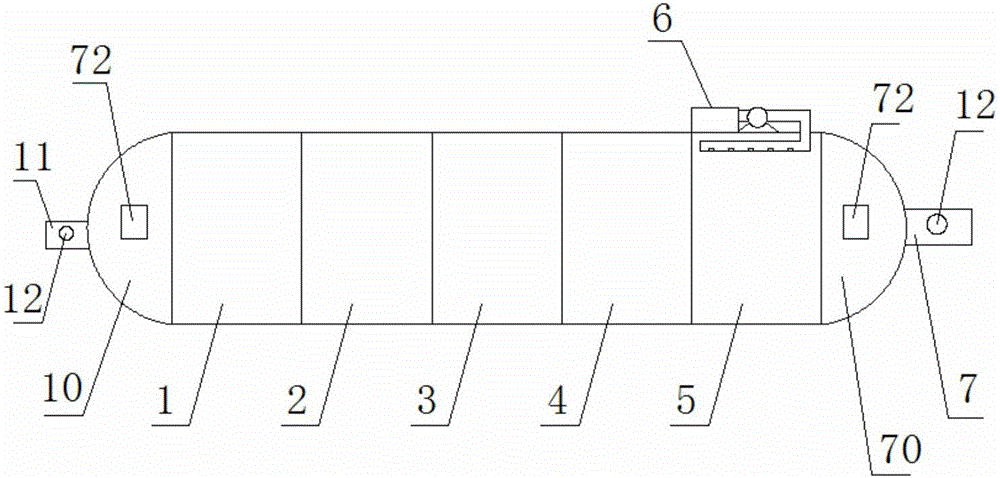

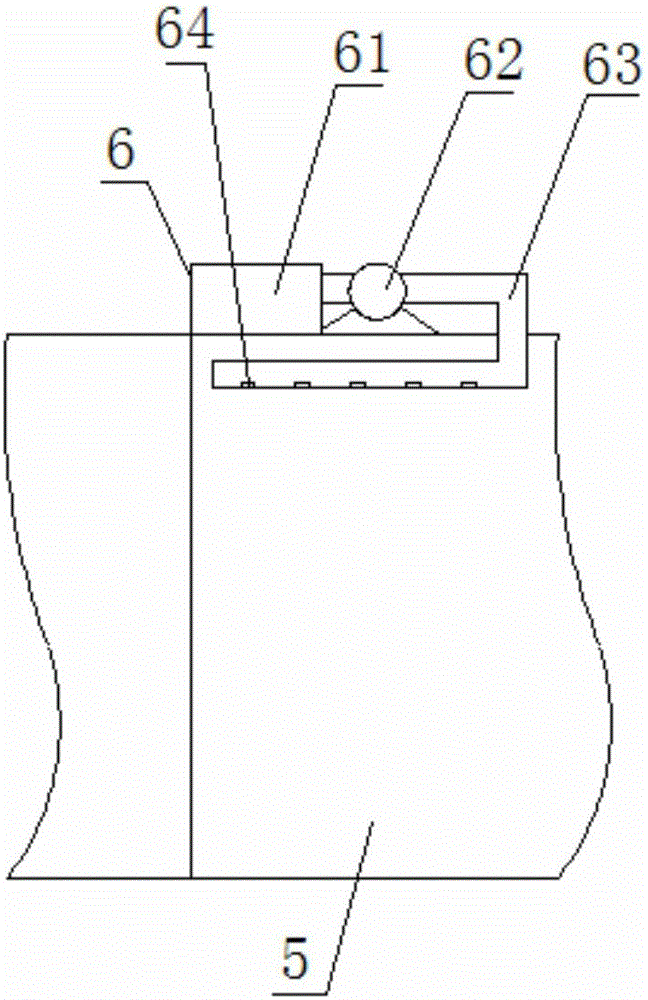

[0031] Such as Figure 1 to Figure 2 As shown, the present invention provides a sewage treatment equipment, comprising: a water inlet 11, a water inlet chamber 10 connected to the water inlet 11, a primary sedimentation chamber 1 connected to the water inlet chamber 1, an aeration chamber connected to the primary sedimentation chamber 1 Oxidation chamber 2, heavy metal reaction chamber 3 connected with aeration oxidation chamber 2, acid-base neutralization chamber 4 connected with heavy metal reaction chamber 3, purification and disinfection chamber 5 connected with acid-base neutralization chamber 4, purification and disinfection chamber 5 connected The water outlet chamber 70, the water outlet 7 connected with the water outlet chamber 70; the purification and disinfection chamber 5 is provided with a dosing device 6; A drug delivery tube 63; a flowmeter 62 is connected in series on the drug delivery tube 63; several drug outlet holes 64 are provided below the drug delivery t...

Embodiment 2

[0035] The drug delivery tube molding material is made of the following raw materials in parts by weight:

[0036] 60 parts of polyvinyl chloride resin, 60 parts of polypropylene resin, 5 parts of processing modifier, 15 parts of methyl methacrylate-butadiene-styrene ternary graft copolymer, 5 parts of antioxidant, lubricant 5 parts, 10-deacetyl baccatin III 5 parts.

[0037] The preparation method of the drug delivery tube molding material, the steps are as follows:

[0038] ①. Add 30 parts of polyvinyl chloride resin, 30 parts of polypropylene resin, 2 parts of processing modification additives, and 5 parts of methyl methacrylate-butadiene-styrene ternary graft copolymer into the stirring equipment, Stirring and mixing at room temperature to obtain premix A;

[0039] ②. Add 5 parts of antioxidant, 5 parts of lubricant, and 5 parts of 10-deacetylbaccatin III into the mixing equipment, stir and mix at room temperature to obtain premix B;

[0040] 3. Add 30 parts of polyviny...

Embodiment 3

[0042] The dosing device for sewage treatment equipment is set above the purification and disinfection room, and includes a liquid medicine box, a medicine delivery tube connected to the medicine solution box and extending to the interior of the purification and disinfection room, and the medicine delivery tube is connected in series There is a flow meter, and several drug outlet holes are arranged under the drug delivery tube; the drug delivery tube is made of drug delivery tube molding material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com