Preparation method of dry powder of wood preservative

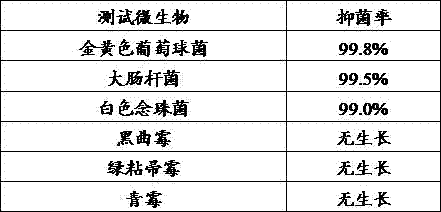

A technology of wood preservative and dry powder, which is applied in the direction of biocide-containing paints, adhesives, fireproof coatings, etc. It can solve the problems of long curing time, easy cracking of phenolic resin adhesive color, high curing temperature, etc., and achieve good flatness , Excellent antibacterial, anti-corrosion and flame retardant properties, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of wood preservative dry powder, described preparation method comprises the steps:

[0028] (1) Prepare the main ingredient: use phenolic resin adhesive as the base material, adjust the pH value to neutral, heat up to 55°C, add an appropriate amount of epoxy resin, maintain constant temperature for 15 minutes, and then cool to room temperature;

[0029] (2) Preparation of functional agent: adequate amount of propolis powder, flame retardant powder, organic bentonite and antioxidants are fully mixed, heated to 65°C to form a stable molten viscous fluid, filtered to remove particulate impurities for later use;

[0030] (3) Prepare the finished adhesive: mix the main agent, functional agent and solvent in an appropriate proportion, and let stand for 8 hours after vacuum degassing;

[0031] (4) The material in step (3) is vacuum removed from the solvent, and the finished wood preservative dry powder is obtained by spray drying;

[0032] The addition ...

Embodiment 2

[0037] The preparation method of wood preservative dry powder, described preparation method comprises the steps:

[0038] (1) Prepare the main ingredient: use phenolic resin preservative dry powder as the base material, adjust the pH value to neutral, raise the temperature to 65°C, add an appropriate amount of epoxy resin, maintain a constant temperature for 5 minutes, and then cool to room temperature;

[0039] (2) Preparation of functional agent: adequate amount of propolis powder, flame retardant powder, organic bentonite and antioxidants are fully mixed, heated to 75°C to form a stable molten viscous fluid, filtered to remove particulate impurities for later use;

[0040] (3) Preparation of the finished adhesive: the main agent, functional agent and solvent are mixed evenly in an appropriate ratio, and left to stand for 8-12 hours after vacuum degassing;

[0041] (4) The material in step (3) is vacuum removed from the solvent, and the finished wood preservative dry powder ...

Embodiment 3

[0047] The preparation method of wood preservative dry powder, described preparation method comprises the steps:

[0048] (1) Prepare the main ingredient: use phenolic resin preservative dry powder as the base material, adjust the pH value to neutral, raise the temperature to 60°C, add an appropriate amount of epoxy resin, maintain constant temperature for 10 minutes, and then cool to room temperature;

[0049] (2) Preparation of functional agent: adequate amount of propolis powder, flame retardant powder, organic bentonite and antioxidants are fully mixed, heated to 70°C to form a stable molten viscous fluid, filtered to remove particulate impurities for later use;

[0050] (3) Preparation of the finished adhesive: the main agent, functional agent and solvent are mixed evenly in an appropriate ratio, and left to stand for 8-12 hours after vacuum degassing;

[0051] (4) The material in step (3) is vacuum removed from the solvent, and the finished wood preservative dry powder i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com