Straw composting method

A composting method and straw technology, applied in the field of agricultural straw resources, can solve the problems of large power consumption, cumbersome composting operations, increased workload, etc., and achieve the effects of simple and easy technology, reduced compost volume, and convenient operation for farmers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

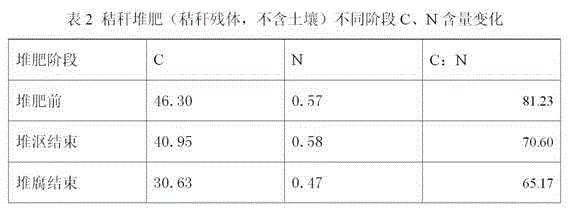

[0024] Embodiment 1 (do not add poultry manure)

[0025] Implementation location: Madian Experimental Station, Mengcheng County, Anhui Province

[0026] Test material: wheat straw in the harvest period

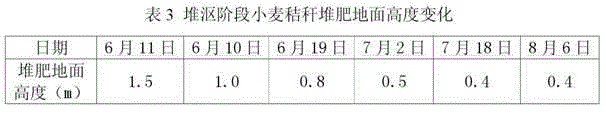

[0027] Straw composting started on June 10, 2014, and the wheat straw composting composting stage (70 days) was from June 10th to August 19th, and the wheat straw composting composting stage (35 days) was from August 19th to September 23rd. . Compost samples were collected at the end of compost retting and composting to analyze the water content and C and N contents.

[0028] How to make wheat straw compost:

[0029] ①. Dig a pit in the field with a length and width of 2 meters and a depth of about 1 meter; ②. Put straw such as wheat into the pit, step on it, add a thin layer of soil for every 50 cm thick straw, and the soil is taken from the soil of the field cultivation layer , the amount of soil added is as soon as the straw is covered, and the straw is piled up to 1.5 ...

Embodiment 2

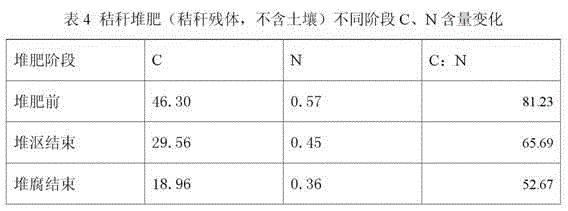

[0037] Embodiment 2 (add poultry and livestock manure)

[0038] Implementation location: Madian Experimental Station, Mengcheng County, Anhui Province

[0039] Test material: wheat straw in the harvest period.

[0040] Straw composting started on June 10, 2014, and the composting stage of wheat straw composting (70 days) was from June 10th to August 19th, and the composting stage of wheat straw composting (35 days) was from August 19th to September 23rd. . Compost samples were collected at the end of compost retting and composting to analyze the water content and C and N contents.

[0041] Wheat Straw Composting Method

[0042] ①. Dig a pit with a length and width of 2 meters and a depth of about 1 meter in the field; ②. Put straw such as wheat into the pit, step on it, and add a small amount of fresh chicken manure for every 50 cm thick straw (300 kg of wheat straw in total) 75 kg of fresh chicken manure), add a small amount of cultivated soil, cover the straw, and pile t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com